Brushless double-feedback motor of winding rotor

A technology of doubly-fed motors and wound rotors, which is applied to asynchronous induction motors, electromechanical devices, electrical components, etc., and can solve the problems of slot space utilization, effective conductor utilization of rotor windings, low winding coefficients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

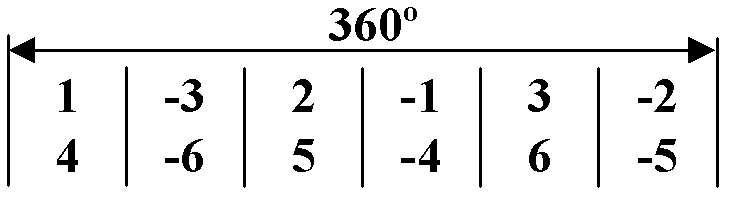

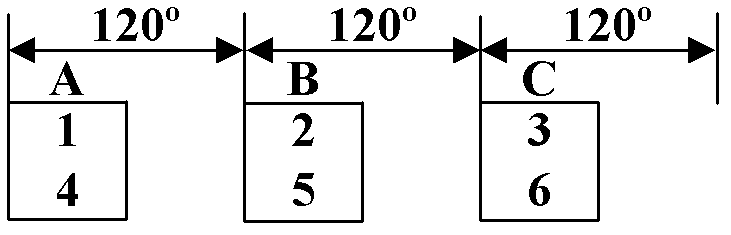

[0070] Including the stator and the rotor, the stator has independent power windings and control windings, and the power windings and control windings are pole pairs p 1 = 2, p 2 = 4 three-phase symmetrical windings; 84 rotor slots are evenly distributed along the circumference on the rotor core, and there are 3-phase rotor windings on the rotor core, and each phase rotor winding has 2 parallel branches, and each parallel branch is composed of two coil groups ,

[0071] In the parallel branch, the first coil group has two coils with different numbers of turns, both of which adopt the first pitch y 1 =11, the total number of coils is 9, and the number of turns of each coil is 14 and 22 respectively; the second coil group has 2 kinds of coils with different numbers of turns, both of which adopt the second pitch y 2 =14, the total number of coils is 4, and the number of turns of each coil is 2 and 7 respectively; the coils in the first coil group are connected in series, the co...

Embodiment 2

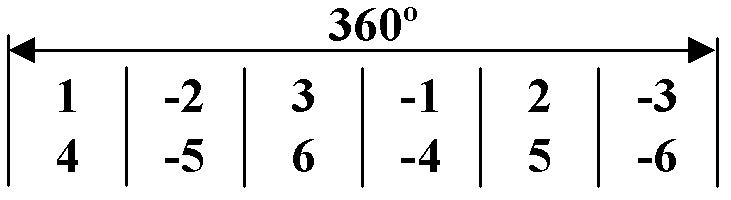

[0078] Including the stator and the rotor, the stator has independent power windings and control windings, and the power windings and control windings are pole pairs p 1 = 2, p 2 = 4 three-phase symmetrical windings; 84 rotor slots are evenly distributed along the circumference on the rotor core, and there are 3-phase rotor windings on the rotor core, and each phase rotor winding has 2 parallel branches, and each parallel branch is composed of three coil groups ,

[0079] In the parallel branch, the first coil group has 4 coils with different numbers of turns, all using the first pitch y 1 = 11, the total number of coils is 10, and the number of turns of each coil is 2, 15, 18 and 21 respectively; the second coil group has 2 kinds of coils with different numbers of turns, all adopting the second pitch y 2 = 14, the total number of coils is 4, and the number of turns of each coil is 2 and 3 respectively; the third coil group has coils with one type of turns, and the third pit...

Embodiment 3

[0086] Including the stator and the rotor, the stator has independent power windings and control windings, and the power windings and control windings are pole pairs p 1 = 2, p 2 = 4 three-phase symmetrical windings; 84 rotor slots are evenly distributed along the circumference on the rotor core, and there are 3-phase rotor windings on the rotor core, and each phase rotor winding has 2 parallel branches, and each parallel branch is composed of two coil groups ,

[0087] In the parallel branch, the first coil group has 4 coils with different numbers of turns, all of which adopt the first pitch y 1 =12, the total number of coils is 10, and the number of turns of each coil is 5, 13, 15 and 21 respectively; the second coil group has 2 kinds of coils with different numbers of turns, all adopting the second pitch y 2 =14, the total number of coils is 8, and the number of turns of each coil is 3 and 4 respectively; the coils in the first coil group are connected in series, the coil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com