High-efficiency precise DC brushless motor

A DC brushless and motor technology, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of high cost of permanent magnet brushless motors, short life and low efficiency of brushed coreless motors, and achieve simplified fan blades Assembly process, low noise, and simple assembly process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

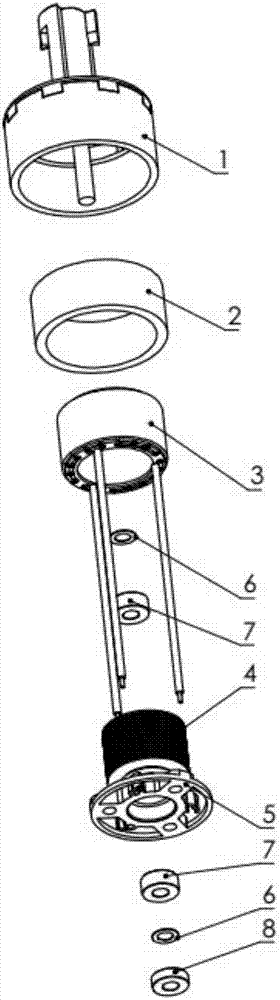

[0029] like figure 1 As shown, it is a high-efficiency precision brushless DC motor proposed by the embodiment of the present invention, which includes an outer rotor assembly 1, a ring magnet 2, an armature winding assembly 3, and a laminated stator installed on the same axis from top to bottom. 4 and the frame assembly 5; wherein, the laminated stator 4 is installed on the middle cylinder of the frame assembly 5, the frame assembly 5 includes a flange 501, a bearing 7 and a gasket 6 arranged in the flange 501, and arranged on The middle cylinder above the flange 501, the front and rear ends of the flange 501 are provided with bearing chambers, and the bearing 7 is installed in the bearing chamber.

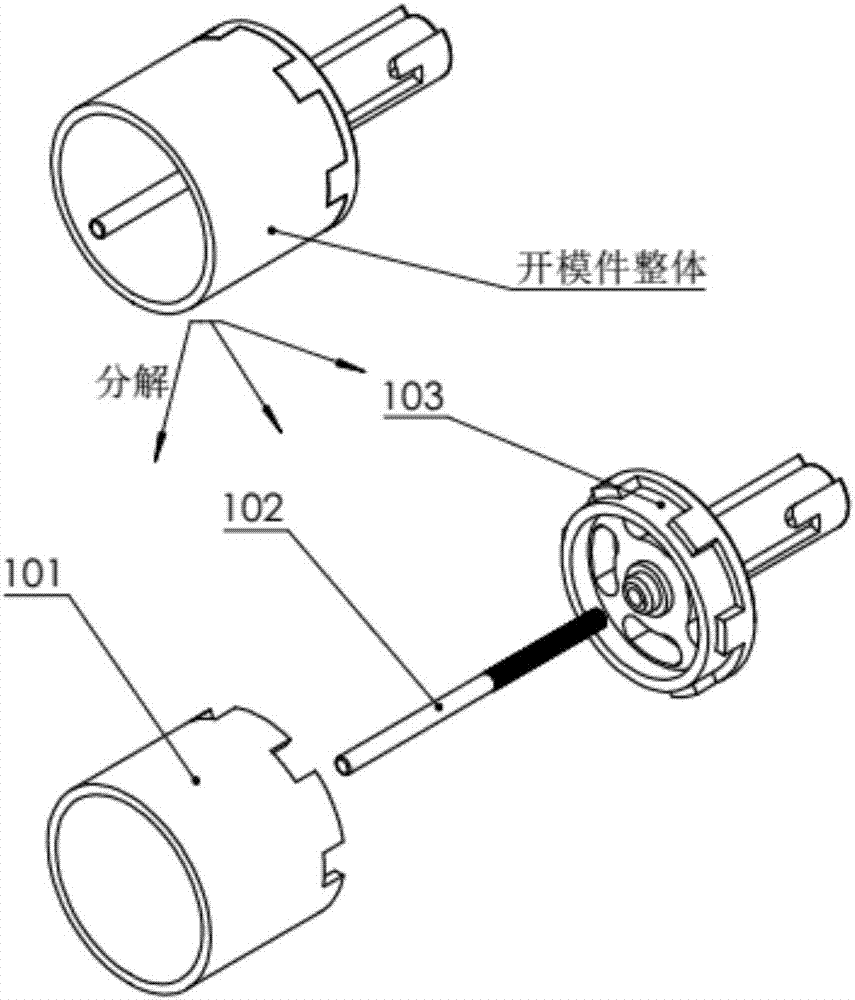

[0030] Further, a circular hole is opened in the middle of the ring magnet 2, and the rotating shaft 102 passes through the hole to set the ring magnet 2 in the casing 101 of the outer rotor assembly 1, and the ring magnet 2 and the casing 101 adopt clearance fit, And fixed by s...

Embodiment 2

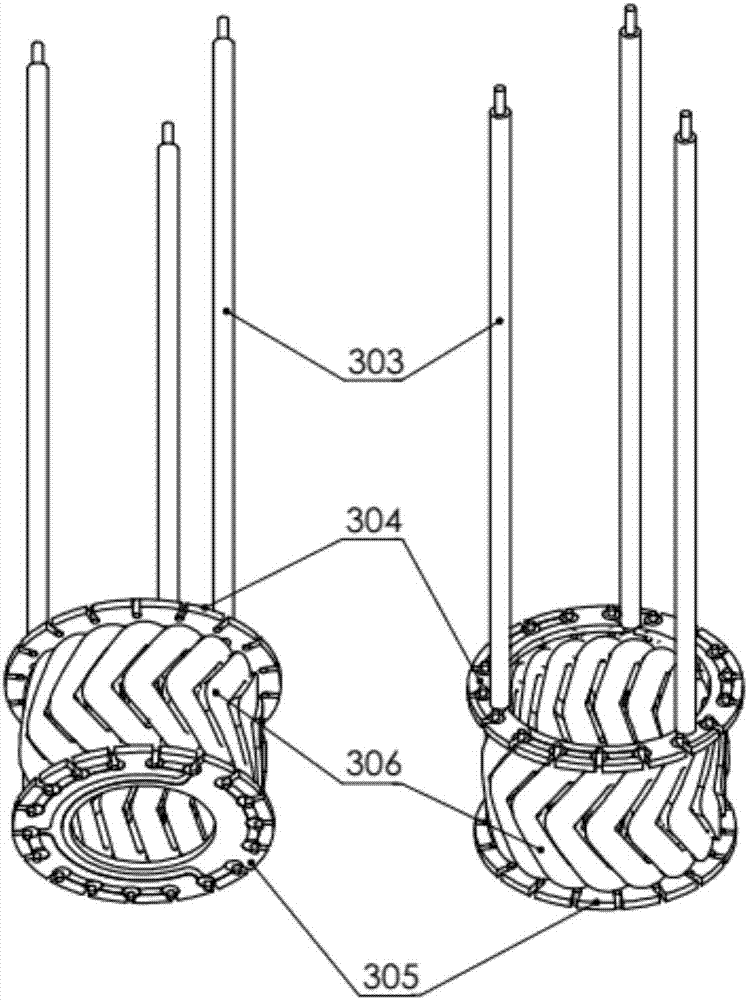

[0043] like Image 6 Shown is the structure of another embodiment of the armature winding assembly 3 of the present invention. The armature winding assembly 3 includes a coreless armature winding 306 , a winding wire head 301 , a connecting buckle 302 and a terminal wire 303 . This solution is mainly aimed at the coreless armature winding 306 produced by the winding process.

[0044] In the second embodiment, an armature winding assembly 3 different from that in the first embodiment is used, and the rest of the components are connected by the same structure.

[0045] like Figure 7 As shown, when the present invention is applied to the direct-drive power motor of the UAV, the end of the front cover is provided with a self-locking structure of the UAV fan blade, which can easily install and disassemble the fan blade, thereby simplifying the assembly process of the UAV fan blade ; And it comes with self-locking structure of fan blades, which avoids the tedious process of screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com