Robot joint based on harmonic wave speed reducer

A technology of harmonic reducer and robot joints, which is applied in the direction of manipulators, components with teeth, manufacturing tools, etc., can solve the problems of increasing the difficulty of processing, low transmission efficiency, and difficulty in realization, and achieve motor life protection, single-stage The effect of large transmission ratio and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is described in more detail below in conjunction with accompanying drawing example:

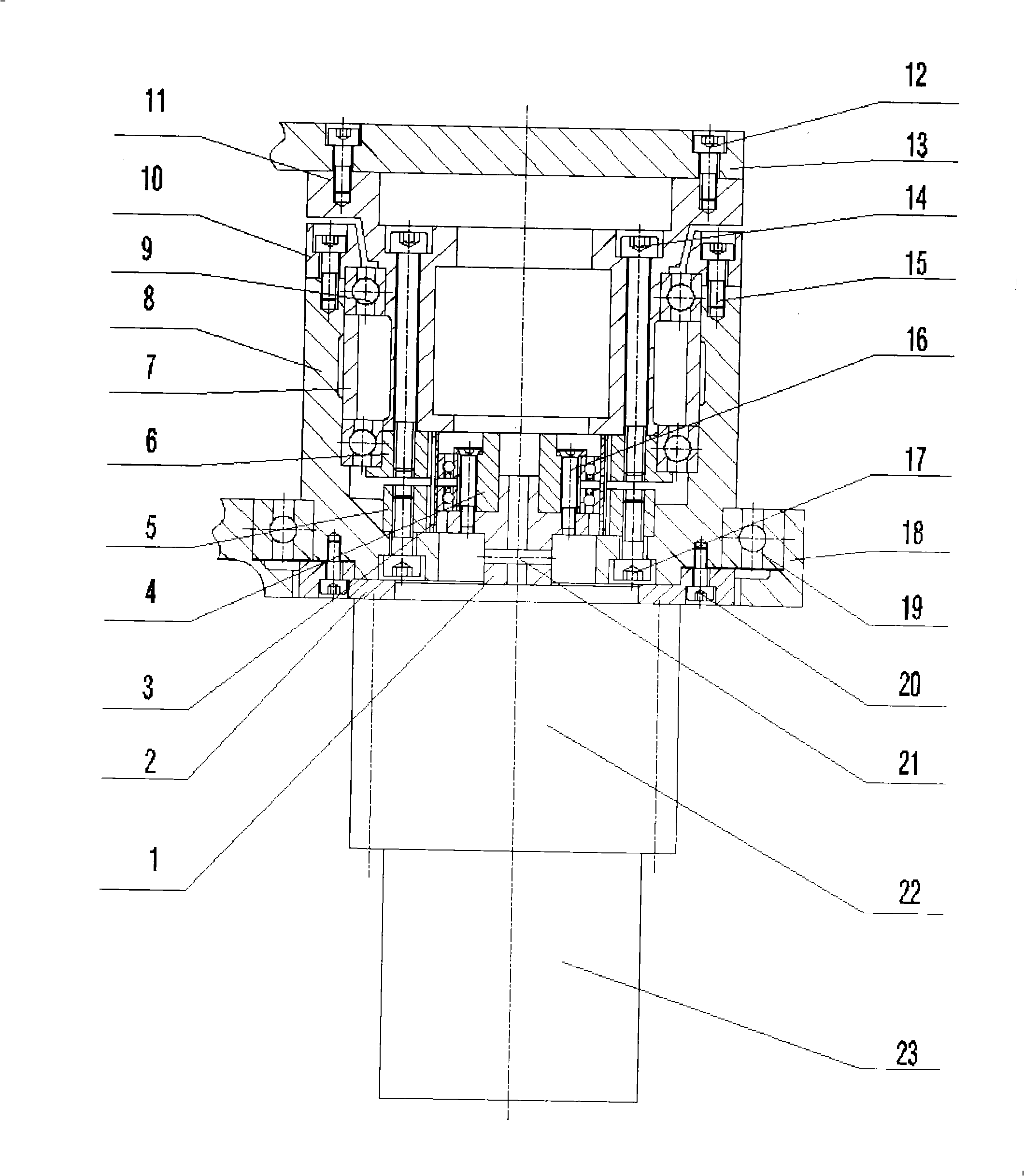

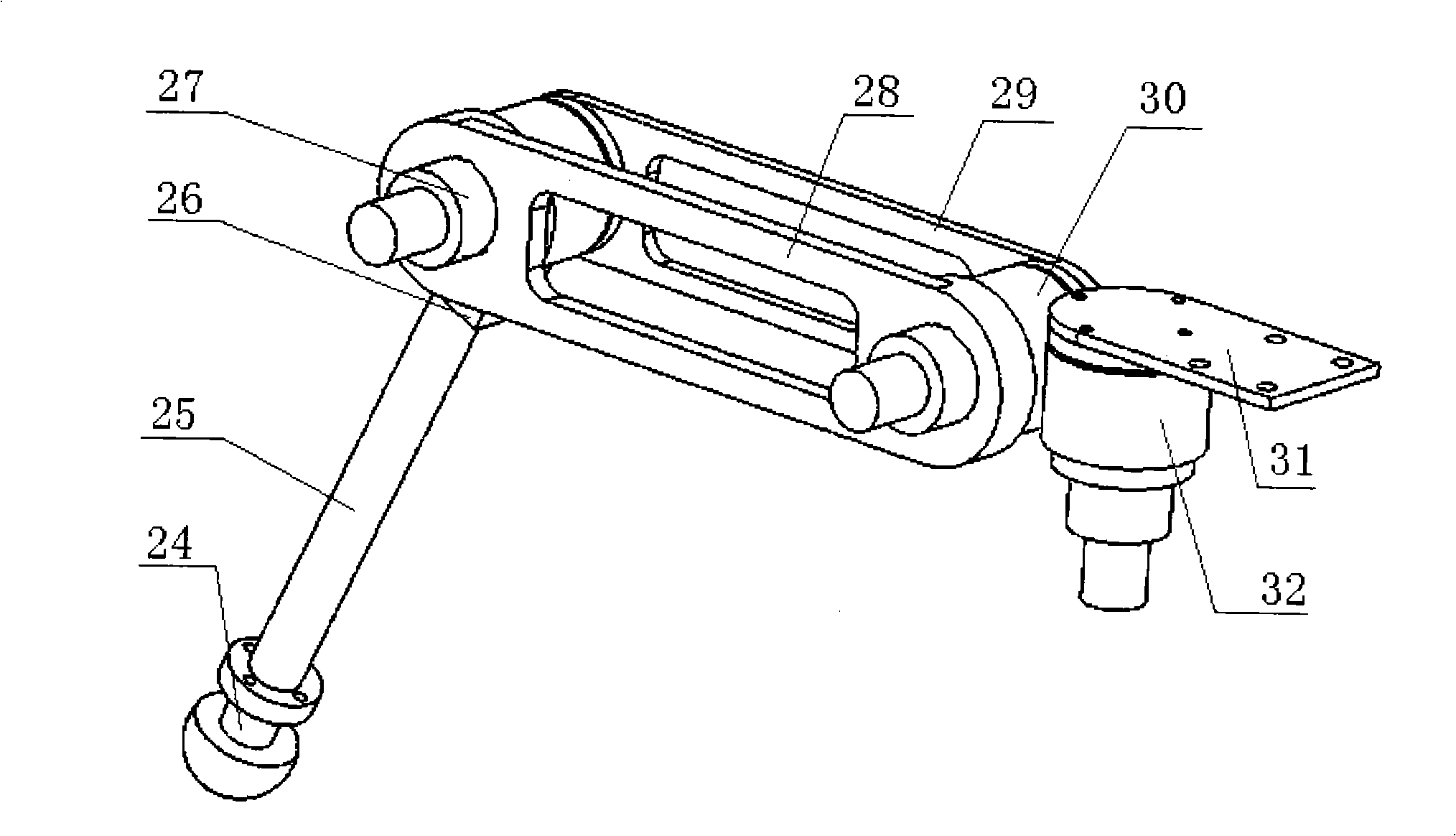

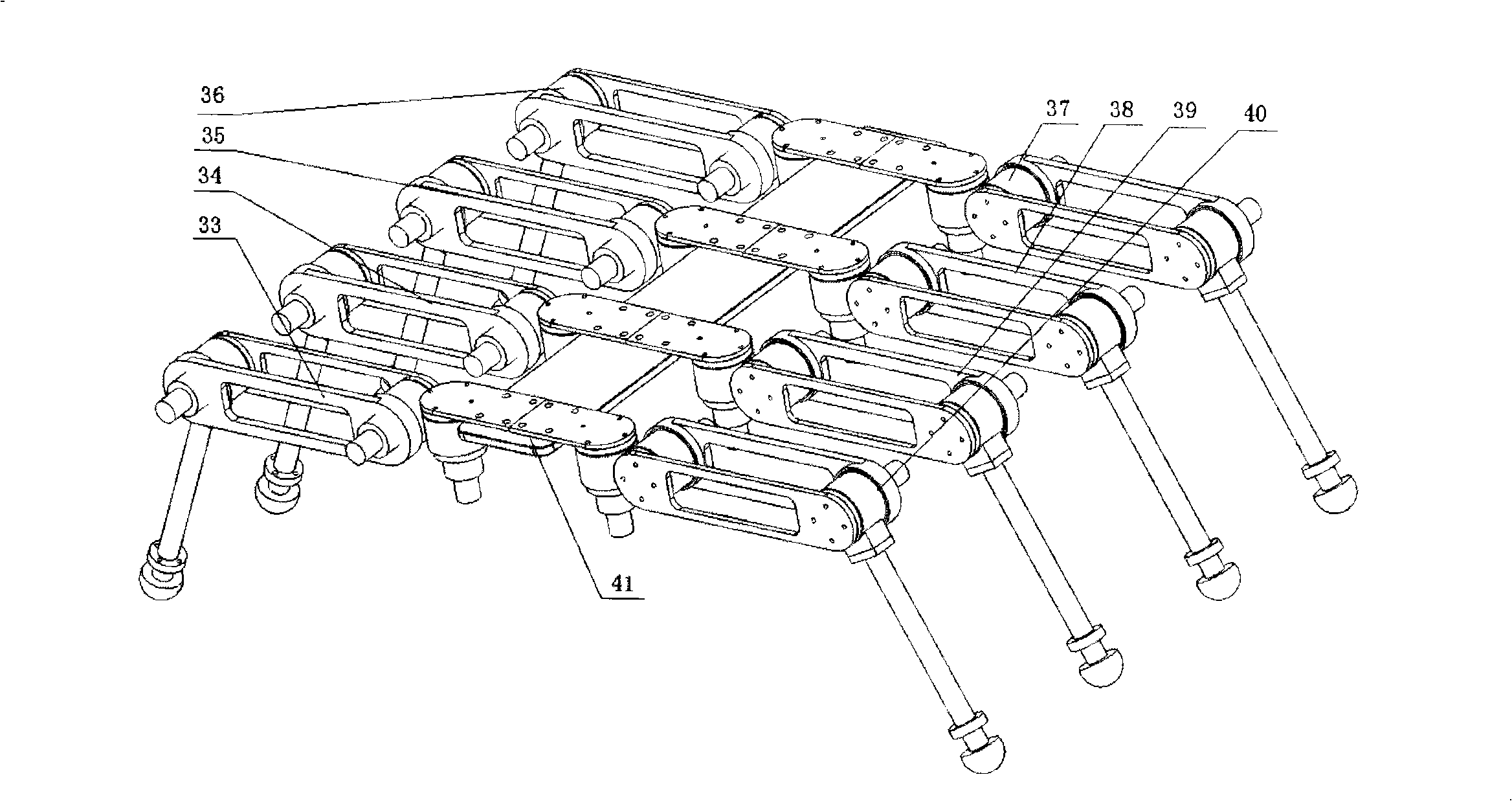

[0029] combine figure 1 , the composition of the robot joint based on the harmonic reducer mainly includes: coupling 1, motor baffle 2, flexible wheel 3, wave generator 4, fixed steel wheel 5, rotating steel wheel 6, bearing sleeve 7, shell 8 , Deep groove ball bearing 9, Bearing bracket 10, End cover 11, Hexagon socket head cylindrical screw 12, Coupling arm 13, Hexagon socket head cylindrical screw 14, Hexagon socket head cylindrical screw 15, Cross recessed countersunk head screw 16, Internal hexagon head Cylindrical screw 17, auxiliary connecting arm 18, deep groove ball bearing 19, hexagon socket head cylindrical screw 20, motor shaft connecting pin 21, motor 22 and photoelectric encoder 23.

[0030] Detailed assembly method: use a coupling 1 to connect the motor 22 through the motor shaft connection pin 21, and the other end of the coupling is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com