Elastically-driven rotational joint

A technology of rotating joints and elastic drive, applied in the directions of manipulators, manufacturing tools, joints, etc., can solve the problems of complex mechanism, difficult installation and maintenance, small driving capacity, etc., and achieve the effect of broad application prospects, convenient installation and maintenance, and large output angle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is described in more detail below in conjunction with accompanying drawing example:

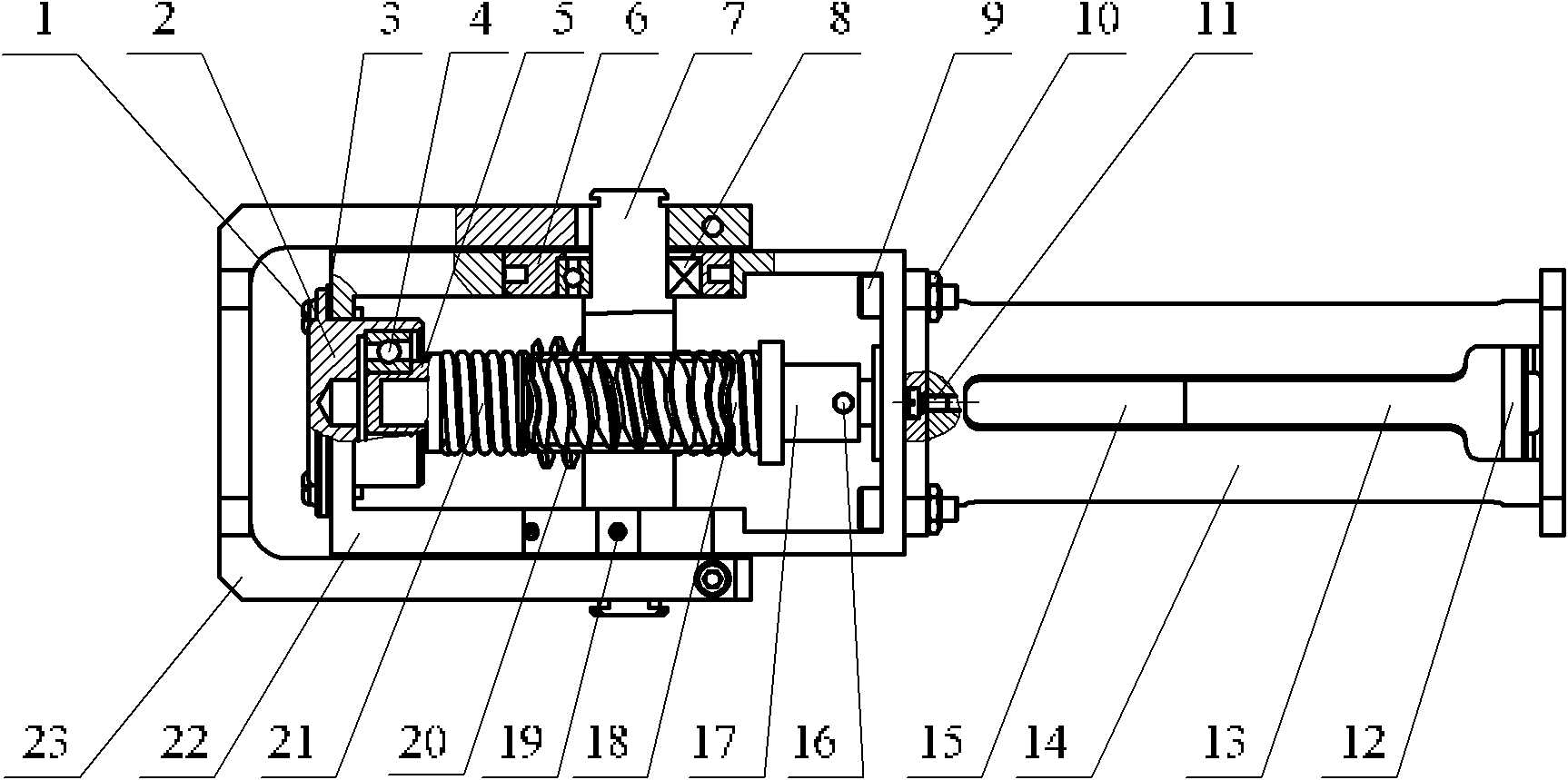

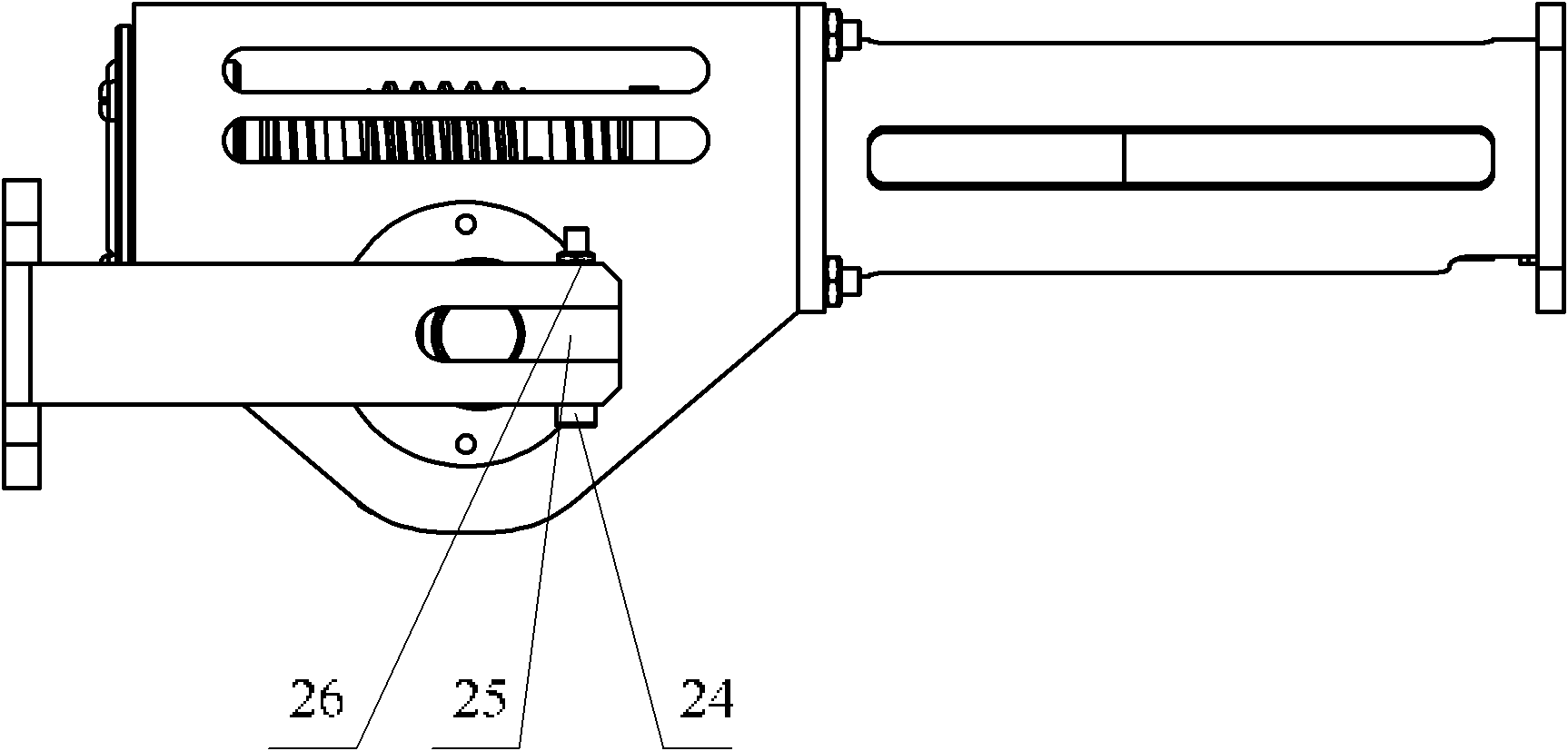

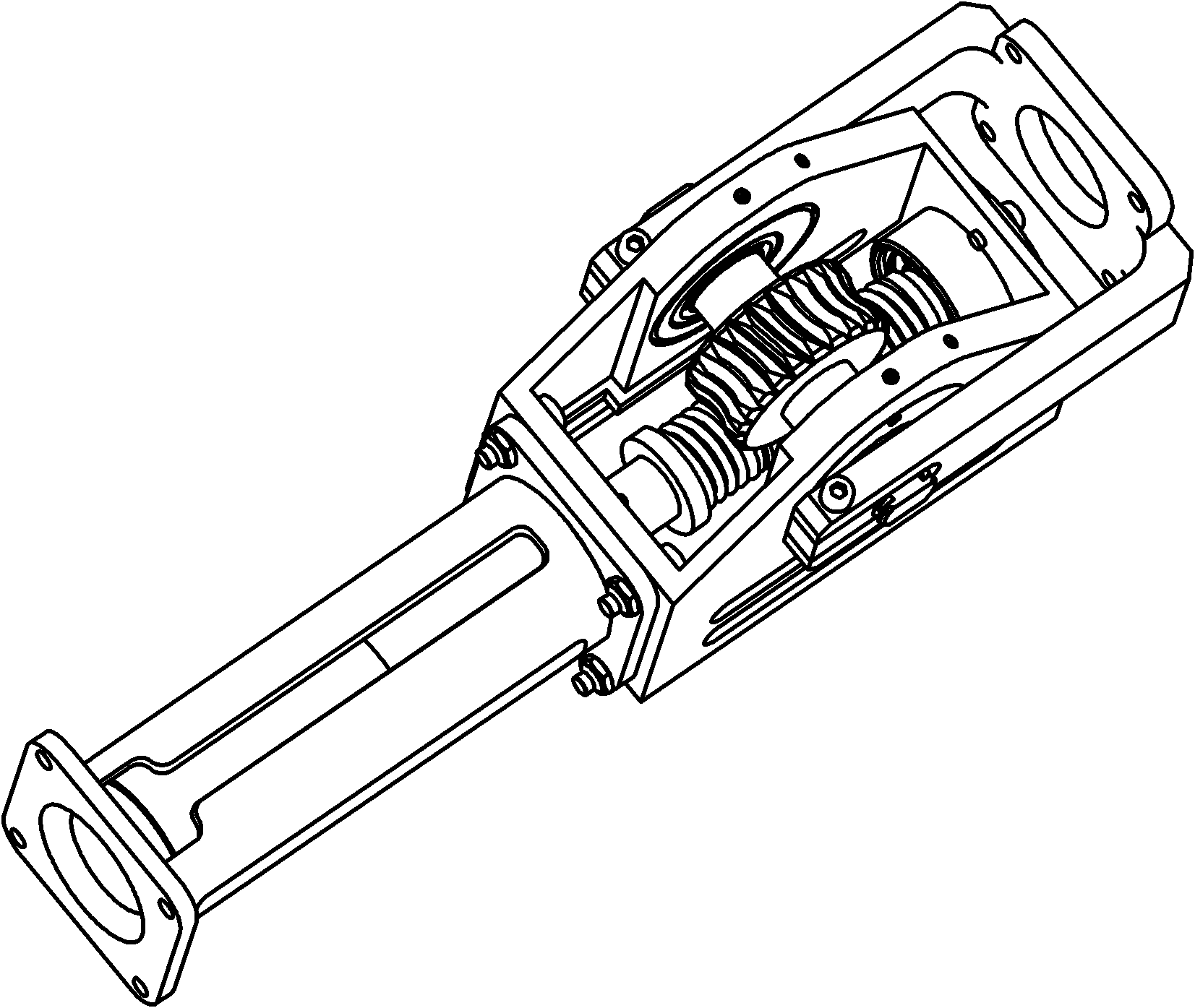

[0018] combine Figure 1 to Figure 3 , the elastically driven rotary joint of the present invention is mainly composed of the following parts: end cover screw 1, adjusting end cover 2, adjusting gasket 3, angular contact ball bearing 4, spring top sleeve 5, eccentric hole copper sleeve 6, worm gear 7 , deep groove ball bearing 8, hexagon socket bolt 9, nut 10, countersunk head screw 11, encoder 12, DC motor 13, motor frame 14, reduction box 15, cylindrical pin 16, spline shaft 17, first spring 18, Set screw 19, worm screw 20, second spring 21, box body 22, output frame 23, hexagon socket head bolt 24, U-shaped groove stopper 25, nut 26.

[0019] The specific implementation method of the present invention is as follows: the box body 22 and the motor frame 14 are connected by four hexagon socket bolts 9, which jointly constitute the supporting frame of the entire j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com