Mobile phone lens cleaning production line device

A production line and lens technology, applied in the direction of transmission, gear transmission, mechanical equipment, etc., can solve the problems of wear, unstable transmission of the production line system, and easy jamming of the transmission belt, so as to achieve smooth transmission, good cleaning effect, and improve cleanliness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to describe the technical solution of the above-mentioned invention in more detail, the following inventors list specific examples to illustrate the technical effects; it should be emphasized that these examples are used to illustrate the present invention and not limit the scope of the present invention.

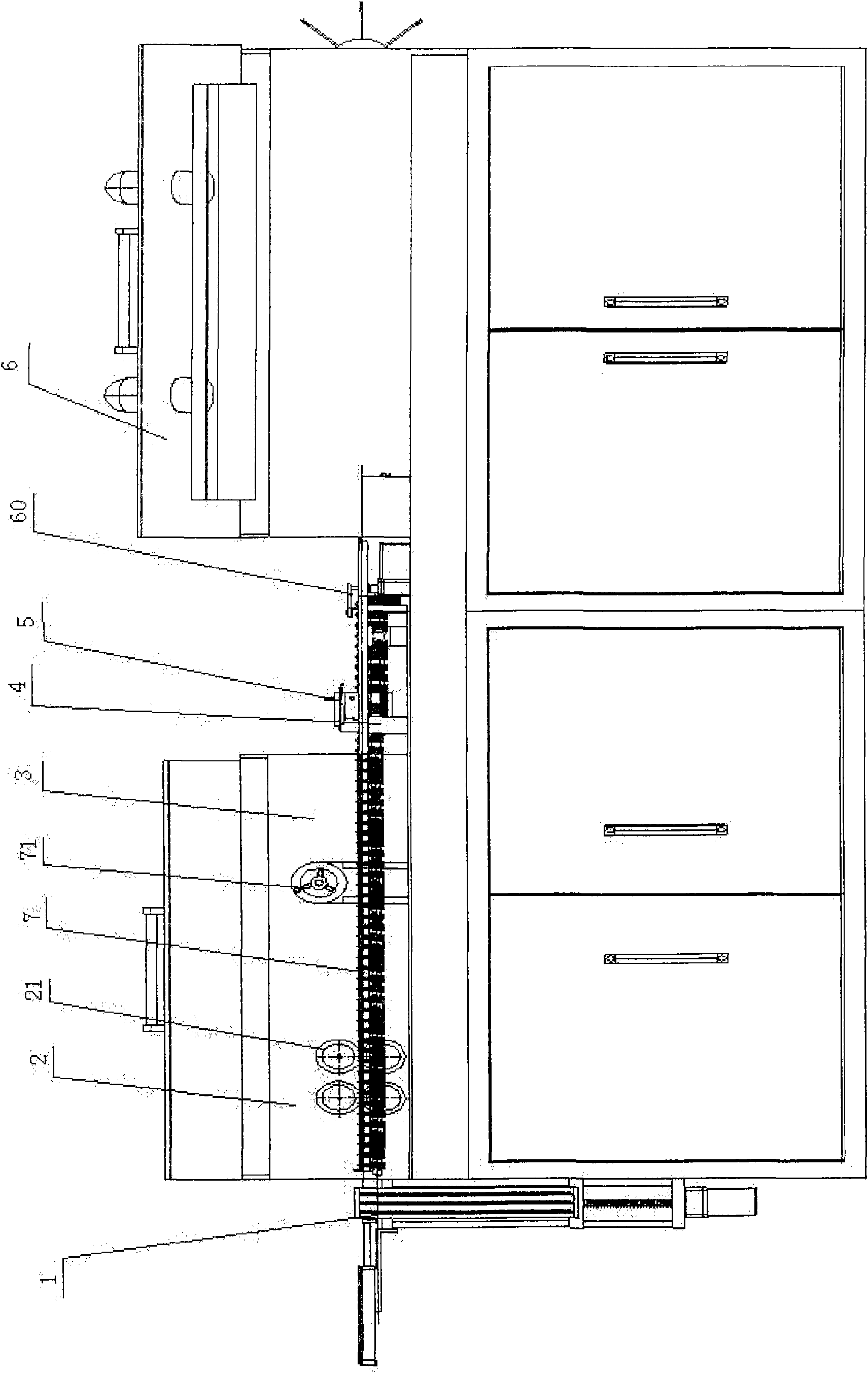

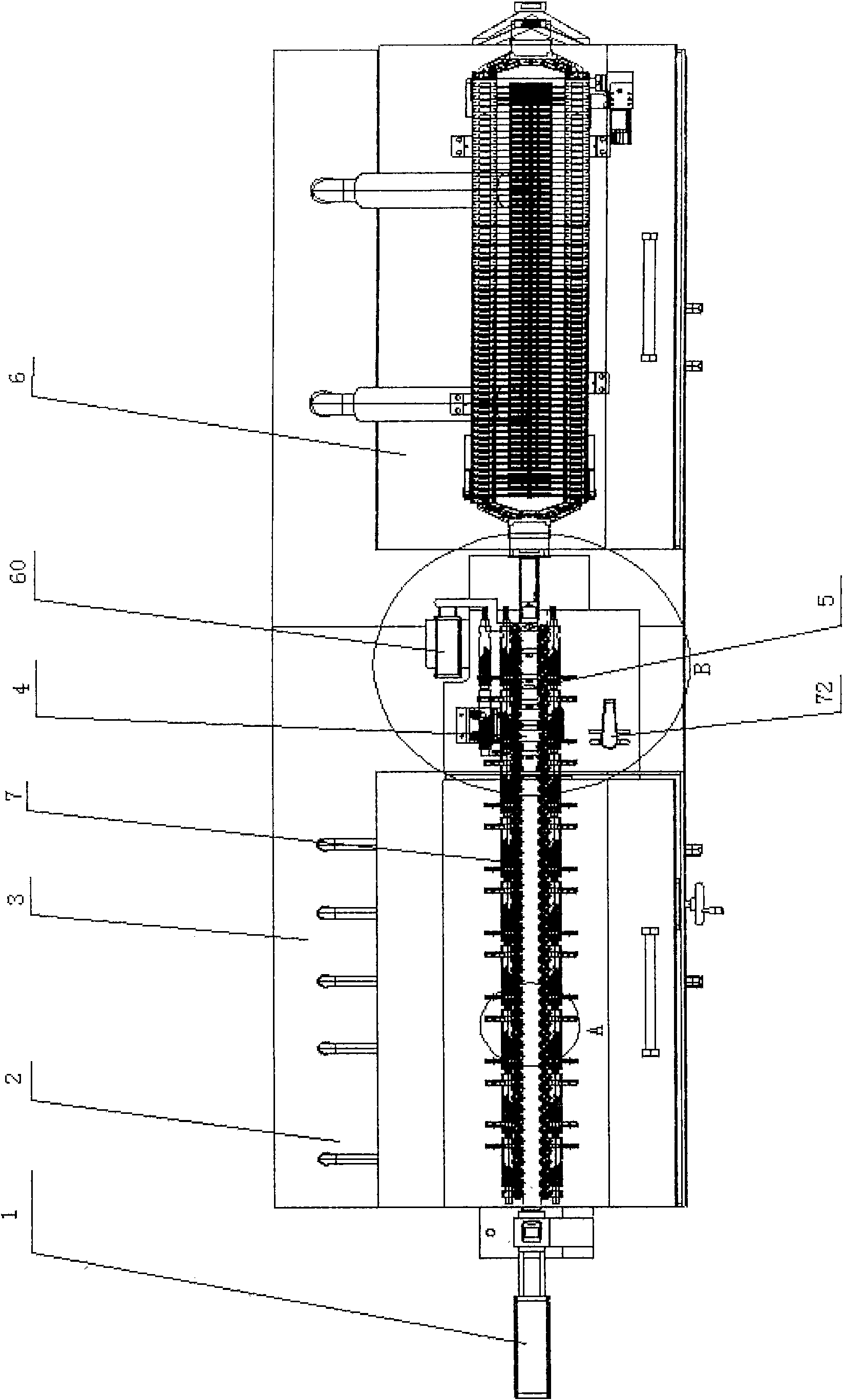

[0036] Example Figures 1 to 4 , the mobile phone lens cleaning production line device, including a feeding mechanism 1, a cleaning mechanism and a drying mechanism 6 arranged in sequence, the feeding mechanism includes a feeder plate and a feed cylinder arranged on the outside of the feeder plate, and the feeder plate The mobile phone lens is laid respectively, and the described feeding cylinder pushes the mobile phone lens on the stock plate backward through the push plate to enter the cleaning mechanism, and the worm and worm gear transmission device 7 is set in the cleaning mechanism to move the mobile phone lens backward.

[0037] The cleaning mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com