High frequency coupling excitation automobile generator

An automobile generator and high-frequency coupling technology, which is applied to synchronous generators, control generators and electrical components through magnetic field changes, and can solve problems such as increasing the heat generation of generators, large volume, and poor low-speed charging performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] Its implementation mode is further described below in conjunction with accompanying drawings.

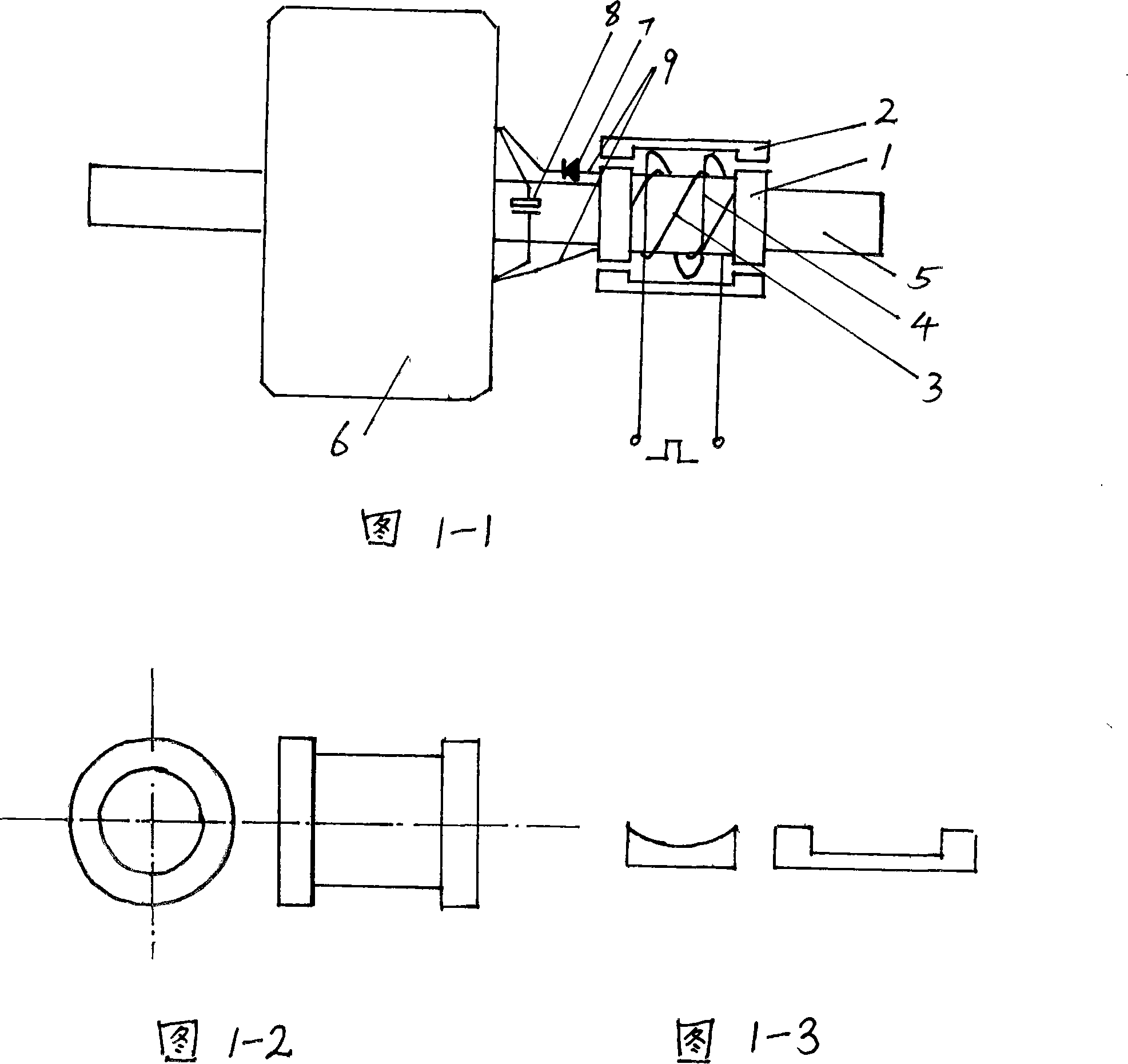

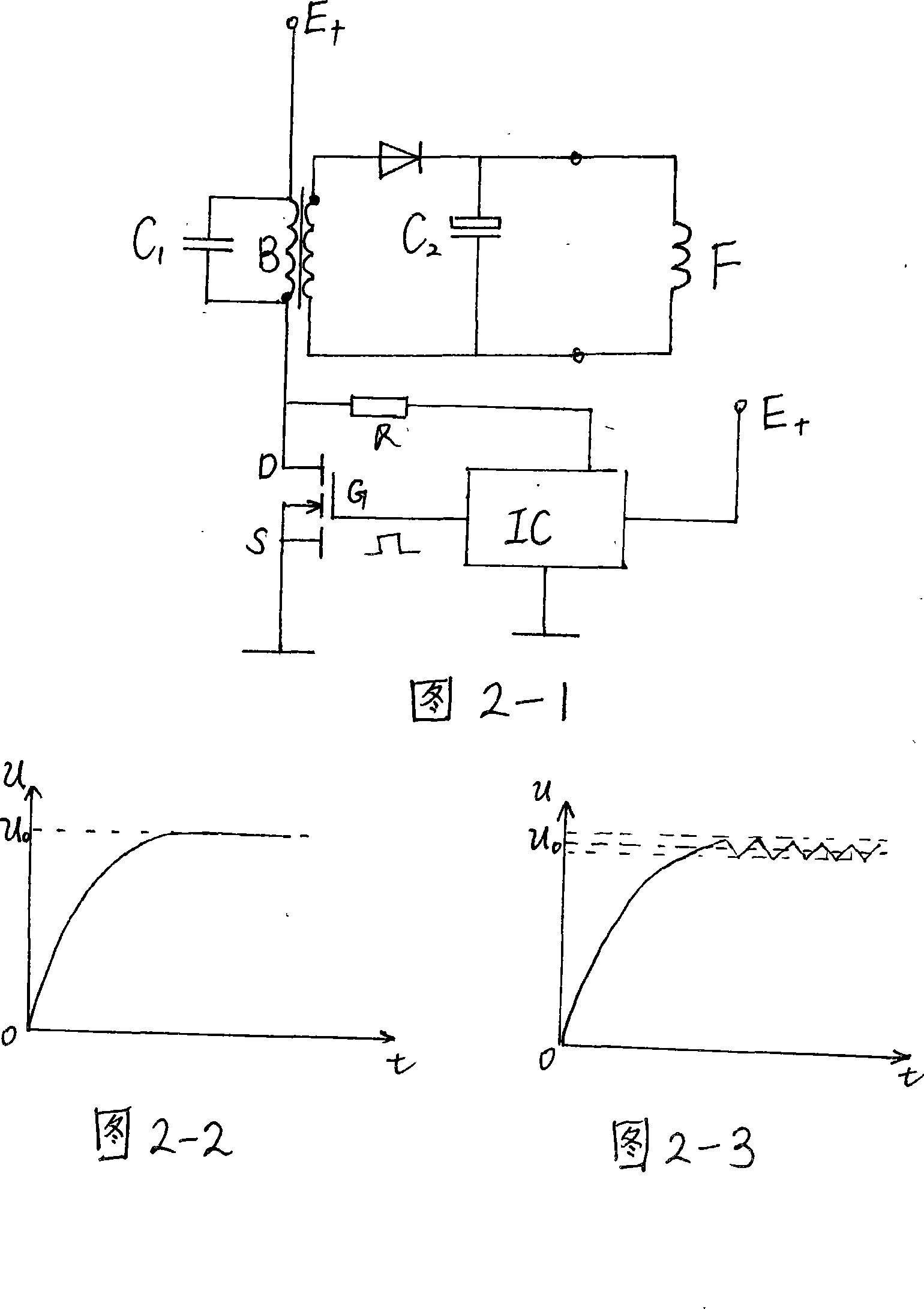

[0009] 1 in Figure 1-1 is a ring-shaped magnetic conductor made of high-frequency magnetic material, and its shape is shown in Figure 1-2. The magnetic ring is placed on the shaft of the generator rotor, and a buffer sleeve of plastic material is used between the magnetic ring and the shaft to fix the magnetic ring and the shaft together. A coil 3 is wound on the magnetic ring, and wires 9 at both ends of the coil are drawn out from one side of the magnetic ring. When the rotor rotates, the magnetic ring rotates with the shaft simultaneously with the coil 3 on it. 4 in the figure is a coil sheathed on the outside of the coil 3, and a strip-shaped magnetizer 2 of the same material as the magnetic ring is arranged above and below the coil 4, and its shape is shown in Fig. 1-3. These two magnetic strips and the coil 4 are made integrally to be enclosed within the outside of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com