Embedded two-layer harmonic drive reducing gear

A technology of harmonic transmission and deceleration device, which is applied in the direction of transmission, transmission parts, gear transmission, etc., can solve the problems of inability to realize super large torque output, insufficient compact distribution, low harmonic rate, etc., and achieve compact structure and structure Sophisticated, Small Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

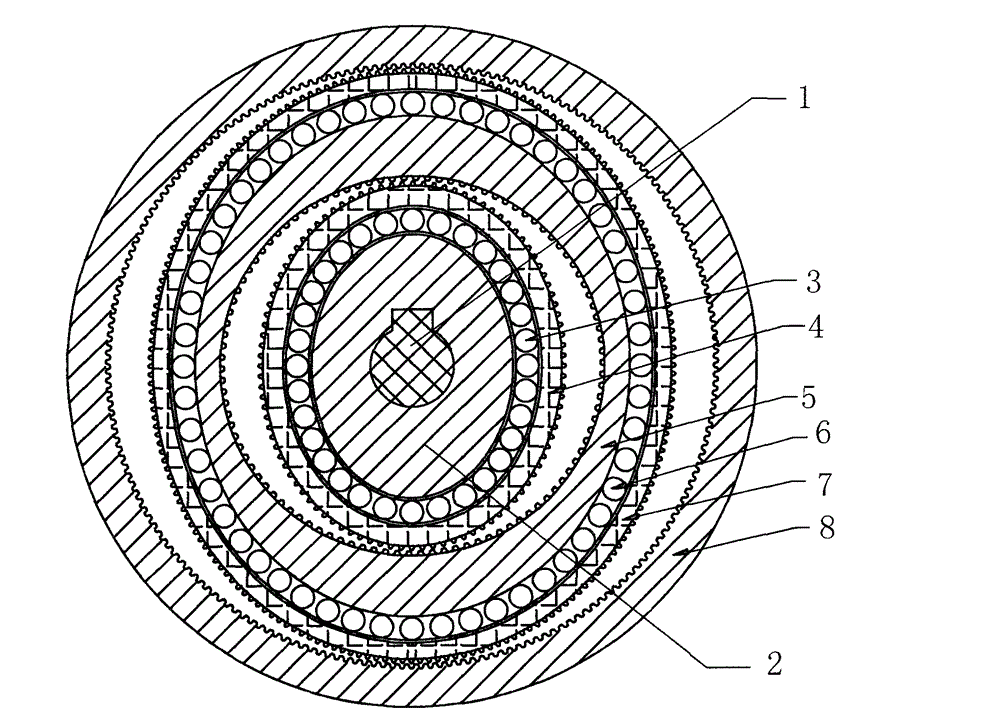

[0015] Such as figure 1 The mosaic type double-layer harmonic drive reduction device shown includes a wave generator. The output end of the wave generator is provided with an input shaft 1, and a cam 2 is installed outside the input shaft 1. It is unique The reason is that the cam 2 used in the present invention is distributed with an inner layer of flexible bearings 3 . Specifically, the inner layer flexible bearing 3 is covered with an inner layer flexible wheel 4 . Looking further, the inner flexible wheel 4 is overcoated with an inner steel wheel 5 , and the inner steel wheel 5 is overcoated with an outer flexible bearing 6 . At the same time, the outer layer flexible bearing 6 is covered with an outer layer flexible wheel 7 , and the outer layer flexible wheel 7 is covered with an outer layer steel wheel 8 .

[0016] As far as a preferred embodiment of the present invention is concerned, the outer circle of the inner steel wheel 5 used is elliptical.

[0017] Judging f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com