Equidirectional multivariable gear speed differential continuously variable transmission for automobile

A continuously variable transmission, multi-variable technology, used in belt/chain/gear, fluid transmission, mechanical equipment, etc., can solve the problem of incapable gear and gear transmission, and achieve excellent transmission performance, low product price, and fuel saving. Effect

Inactive Publication Date: 2011-06-15

罗永

View PDF4 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the current gear transmission devices are all step-variable, that is, after the driving gear is separated from the force transmission relationship with a fixed speed, it establishes a force transmission relationship with another fixed speed, so that the output can change the speed in a step-by-step state, and the gear cannot be connected with the power transmission relationship. The transmission of the gear forms the transmission relationship between the input and several output speed values under the condition of continuous engagement of the force, so that the output produces a gradual change in the speed and forms a continuously variable speed

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

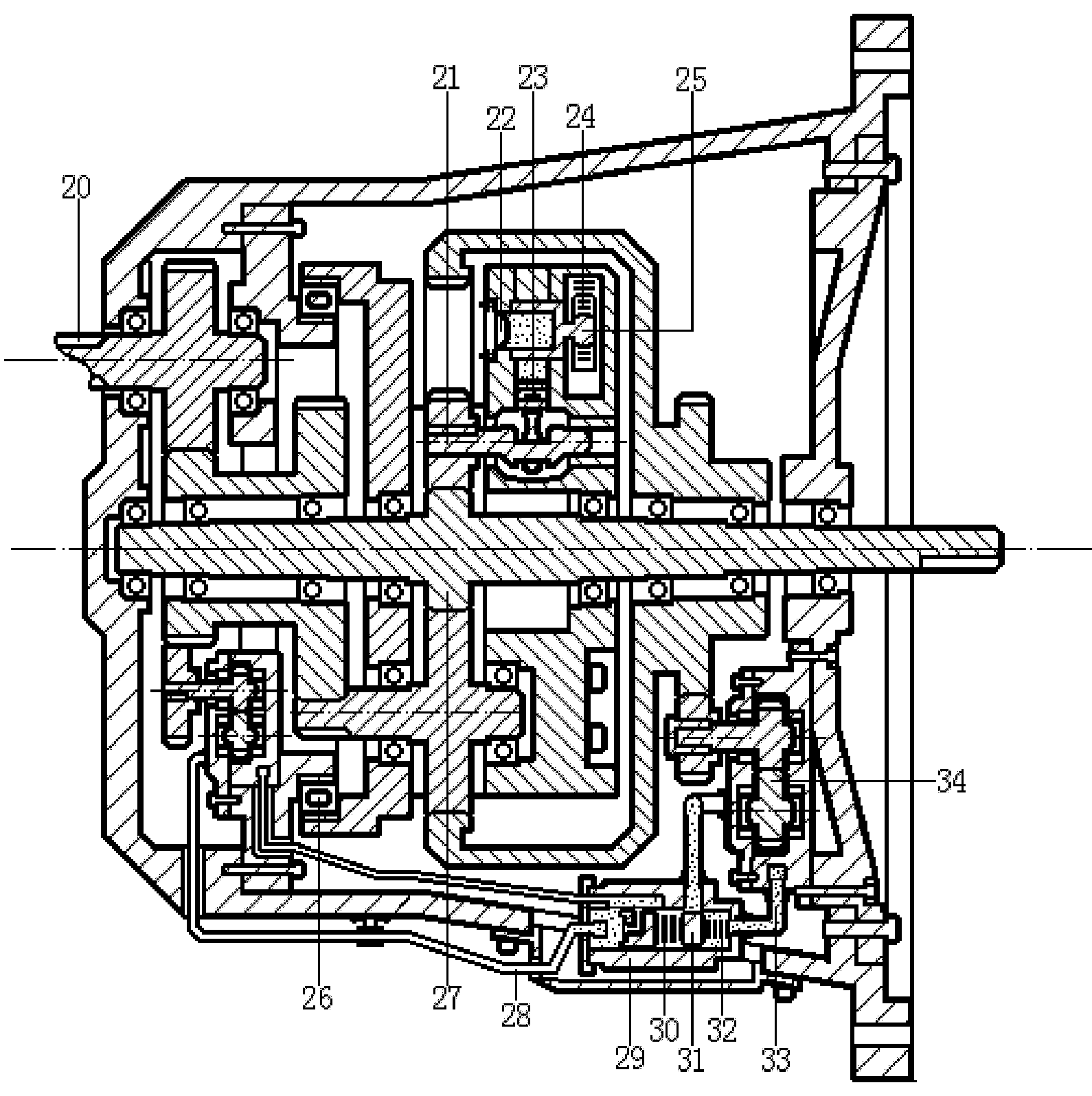

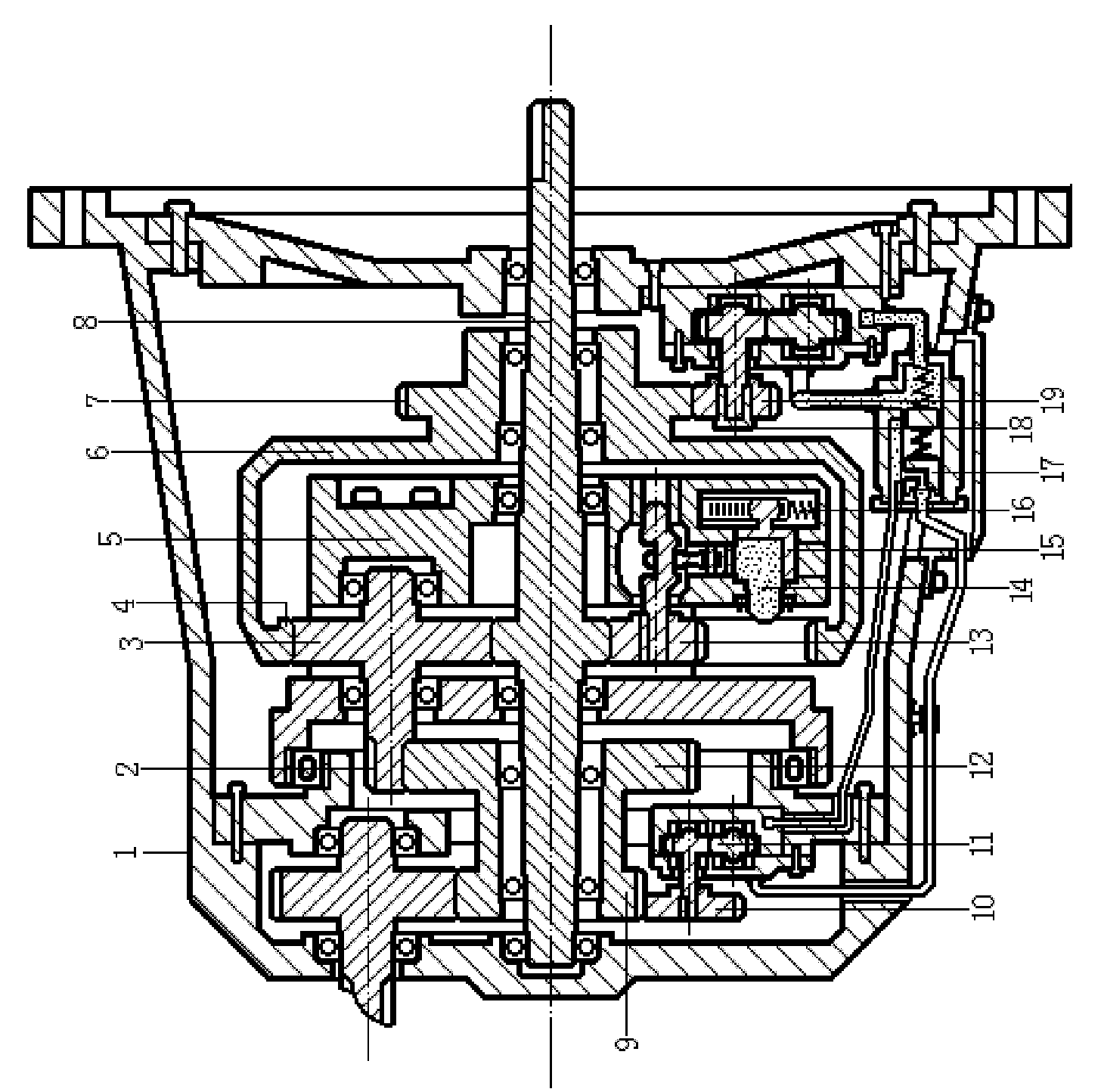

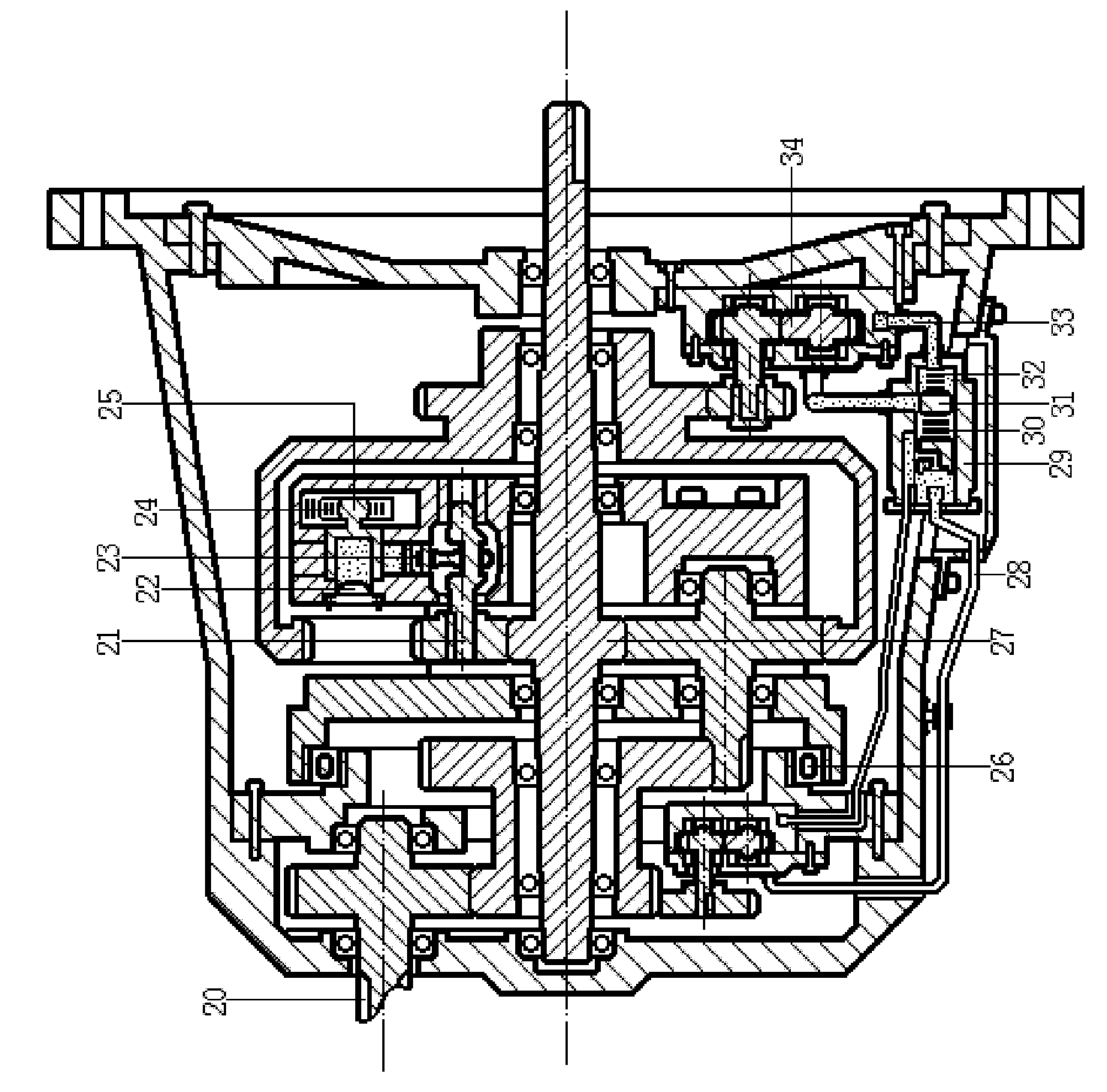

The invention discloses an equidirectional multivariable gear speed differential continuously variable transmission for an automobile, and relates to a gear continuously variable transmission device for the transmission of a large-power automobile. The speed changing method for the gear continuously variable transmission device is as follows: the planetary equidirectional variable speed difference generated by the rated deceleration and hydraulic damping of a gear enable the gradual changes of rotation speed to be output and generated, and the stepless speed change is generated by the output gear at an uninterrupted meshed state caused by the cyclic variable of the output rotation speed and the hydraulic damping. The continuously variable transmission has the advantages of high transmission power, high variable speed ratio, excellent variable speed performance and high mechanical strength, can be configured to a car of large displacement, an SUV (sports utility vehicle), a bus, a truck and even a heavy type automobile to realize the stepless speed change, has a simple structure, is made of normal materials, has low manufacturing cost, and ensures long service lives of the products.

Description

Co-direction multi-variable gear differential continuously variable transmission for vehicle Technical field The invention relates to a continuously variable transmission device for automobiles with high torque and high power transmission. Background technique Continuously variable transmission can improve the driving quality of the car, improve the transmission energy efficiency of the engine to the greatest extent, and save fuel. It is recognized by the industry as the most ideal car transmission method. However, the continuously variable transmissions that can be used in automobiles are all mechanical friction types such as: CVT, DCT, KRG, etc. As we all know, the transmission efficiency of mechanical friction depends on the size of the mechanical friction coefficient; variable transmission with high torque, high power, and high ratio will cause high-intensity friction in mechanical friction transmissions, which will accelerate the wear of the machinery and reduce the m...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F16H47/04

Inventor 罗永

Owner 罗永

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com