Tape measure and driving mechanism thereof

A driving mechanism and a tape measure technology, applied in the direction of a bendable ruler, etc., can solve the problems of increased thickness of the tape measure shell, unfavorable hand-holding operation, increased volume, etc., to achieve easy assembly, avoid excessive speed, and stable and reliable performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

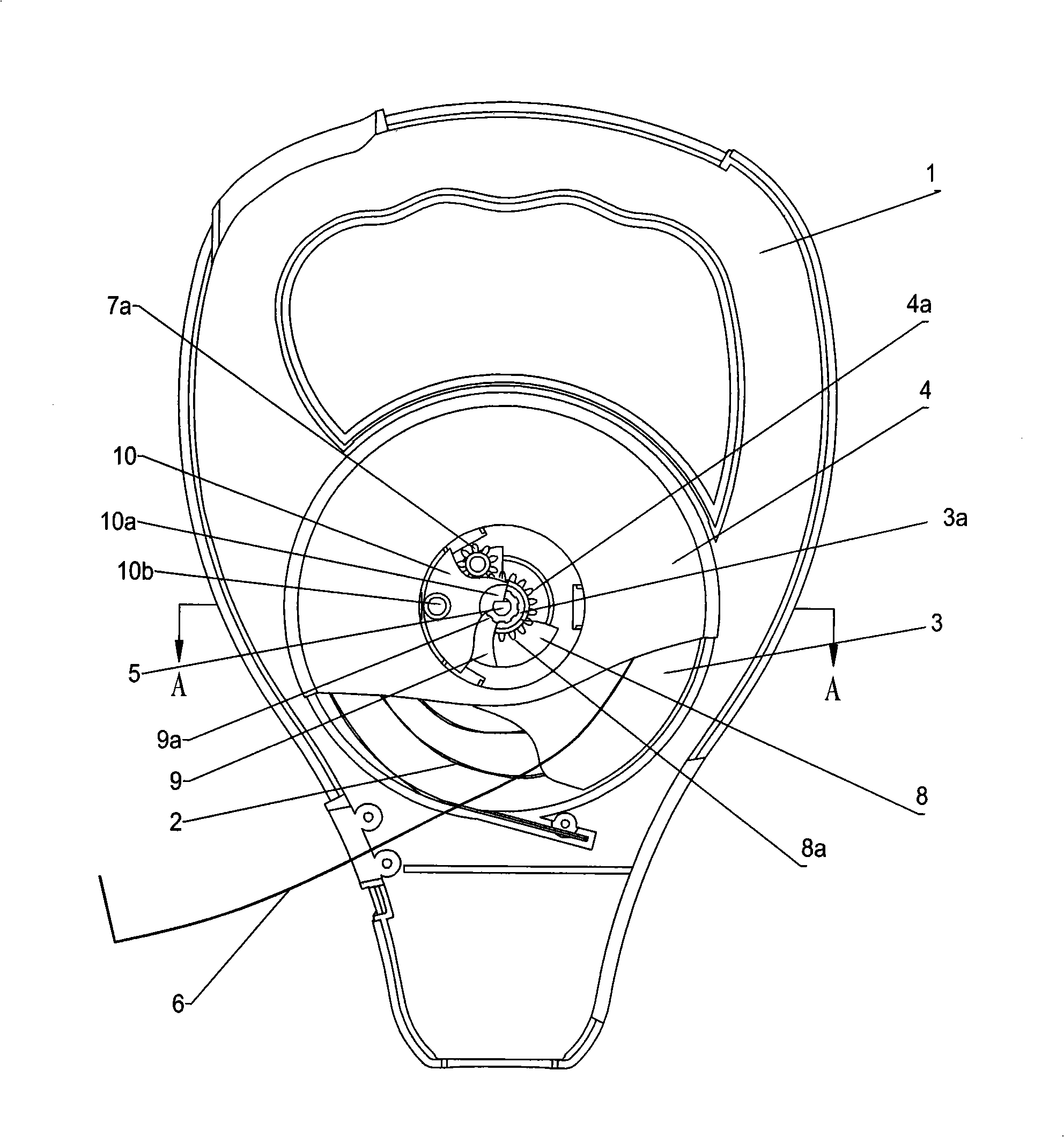

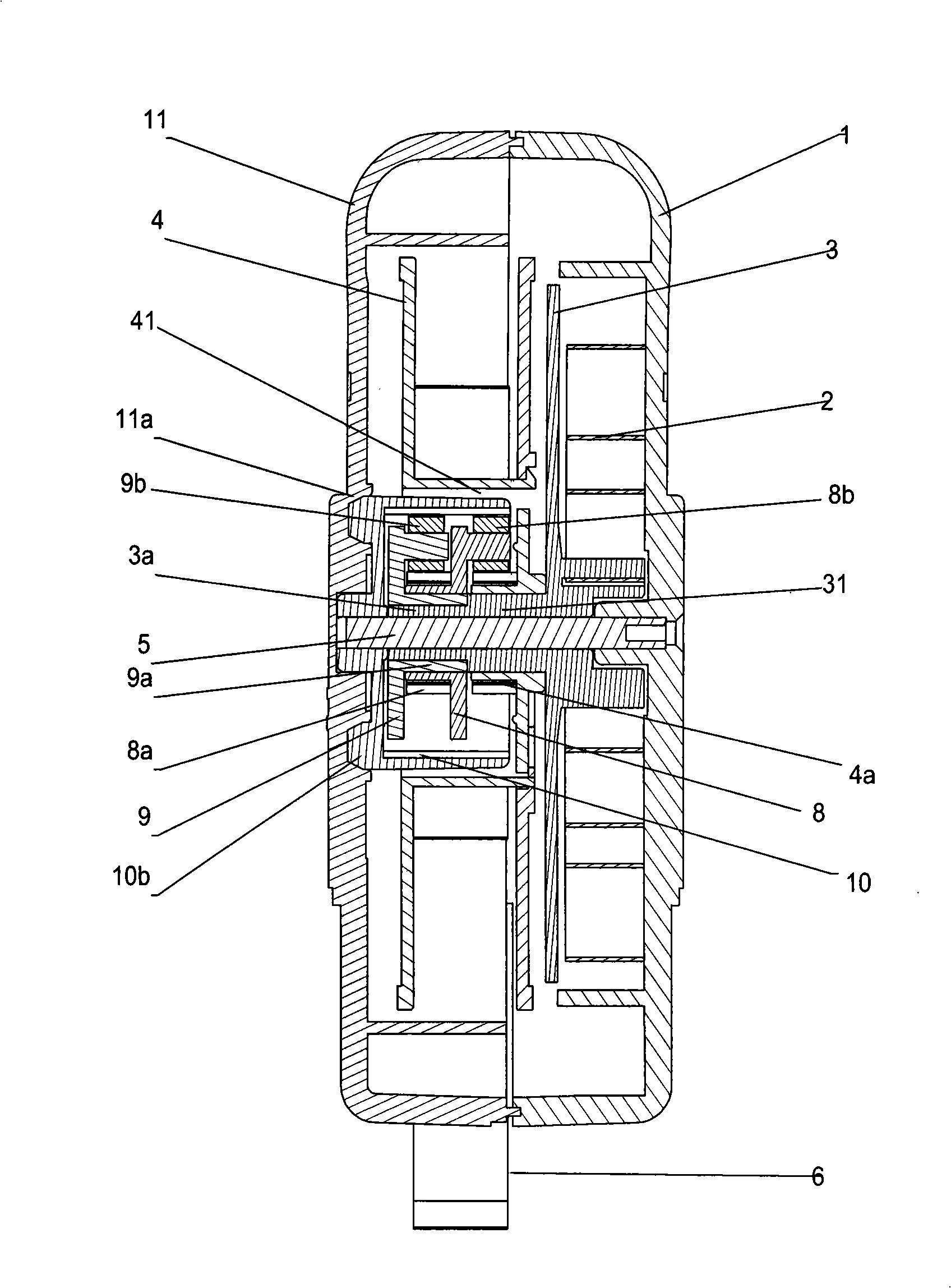

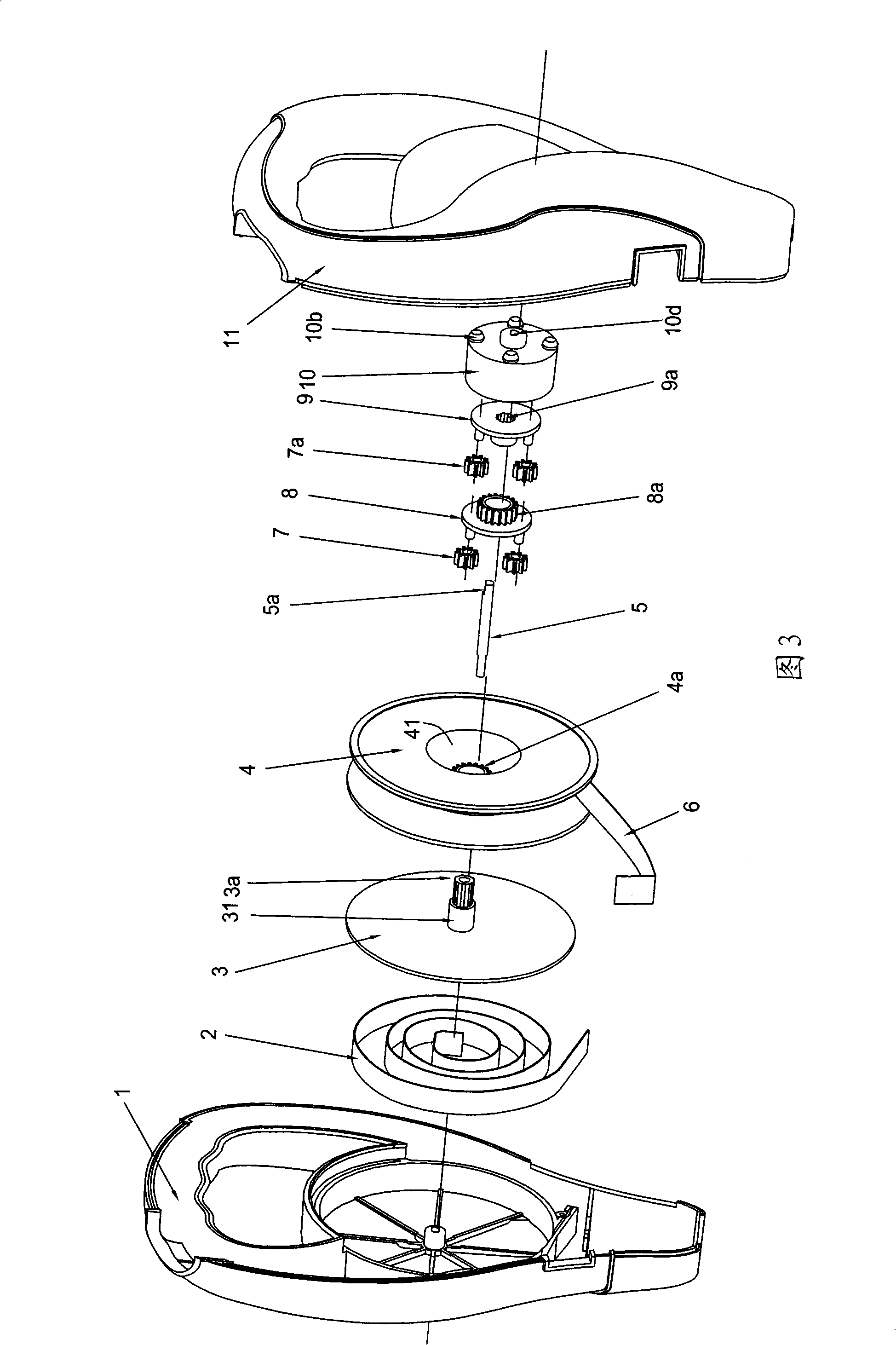

[0045] Example 1: Reference figure 1 , figure 2 , Figures 3 and 4, the tape measure with a planetary gear transmission mechanism in this embodiment includes a scale housing, a scale core disc 4, a scale reed disc 3 and a planetary gear mechanism.

[0046] The scale shell is assembled and matched by the regular scale shell 11 and the reverse scale shell 1, and is connected with screws after being combined, so that an accommodating cavity is formed between the regular scale shell 11 and the reverse scale shell 1. The chi core disc 4 is rotatably arranged in the space on one side of the cavity of the chi shell, and is used to drive the chi tape 6 to be extracted and rolled up. Correspondingly, there is an opening for the chi tape 6 to protrude in the chi shell, and The inner side of the core disk 4 has a center gear 4a facing inward, and the ruler spring disk 3 is located in the space on the other side of the cavity of the ruler housing, and has a retracted ruler spring 2, whic...

Embodiment 2

[0055] Example 2: Reference Figure 5 As shown in Figure 8,

[0056] The planetary gear reduction mechanism includes the main components such as the first planet carrier 8 , the first planetary gear set 8 b , the second planet carrier 9 , the second planetary gear set 9 b and the inner gear sleeve 10 .

[0057] The outer part of the core disc 4 has an inward central gear 4a;

[0058] The first planet carrier 8 has a central transmission gear 8a at the top;

[0059] The first planetary gear set 8b is rotatably arranged on the first planet carrier 8 and meshes with the sun gear 4a in the middle of the core disc 4;

[0060] The second planet carrier 9, the center is connected with the ruler spring 2 through a connecting groove or a connecting piece;

[0061] The second planetary gear set 9b is rotatably arranged on the second planet carrier 9 and meshes with the sun gear 8a of the first planet carrier; and

[0062] The inner gear sleeve 10, the inner wall has a ring gear mesh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com