Two-stage friction type dual-mass flywheel

A dual-mass flywheel, friction-type technology, applied in vibration suppression adjustment, spring/shock absorber, mechanical equipment, etc., can solve the problems of small torsion angle and ineffective reduction of torsional stiffness, avoiding resonance and excellent vibration reduction. Effects, effects with a simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

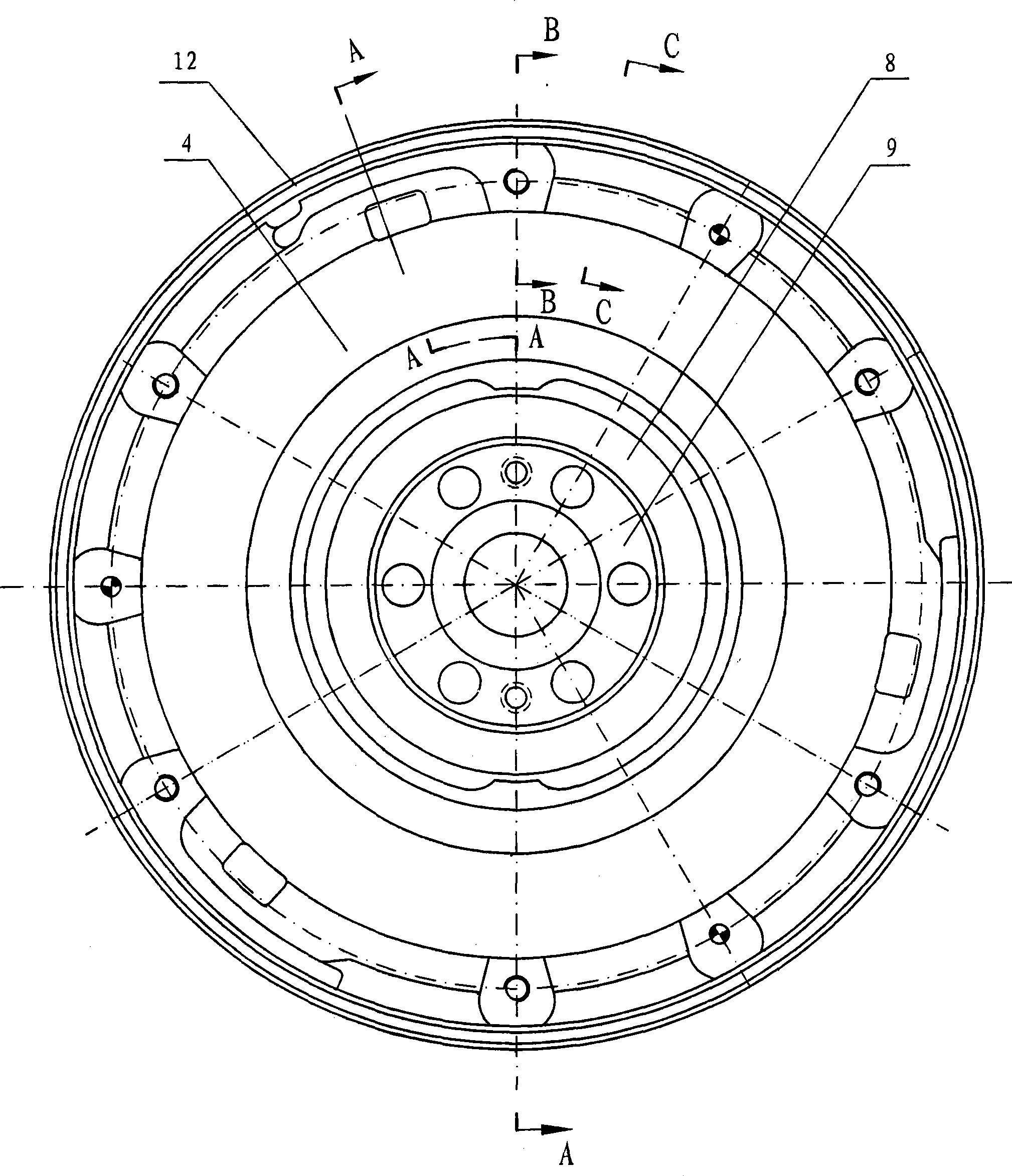

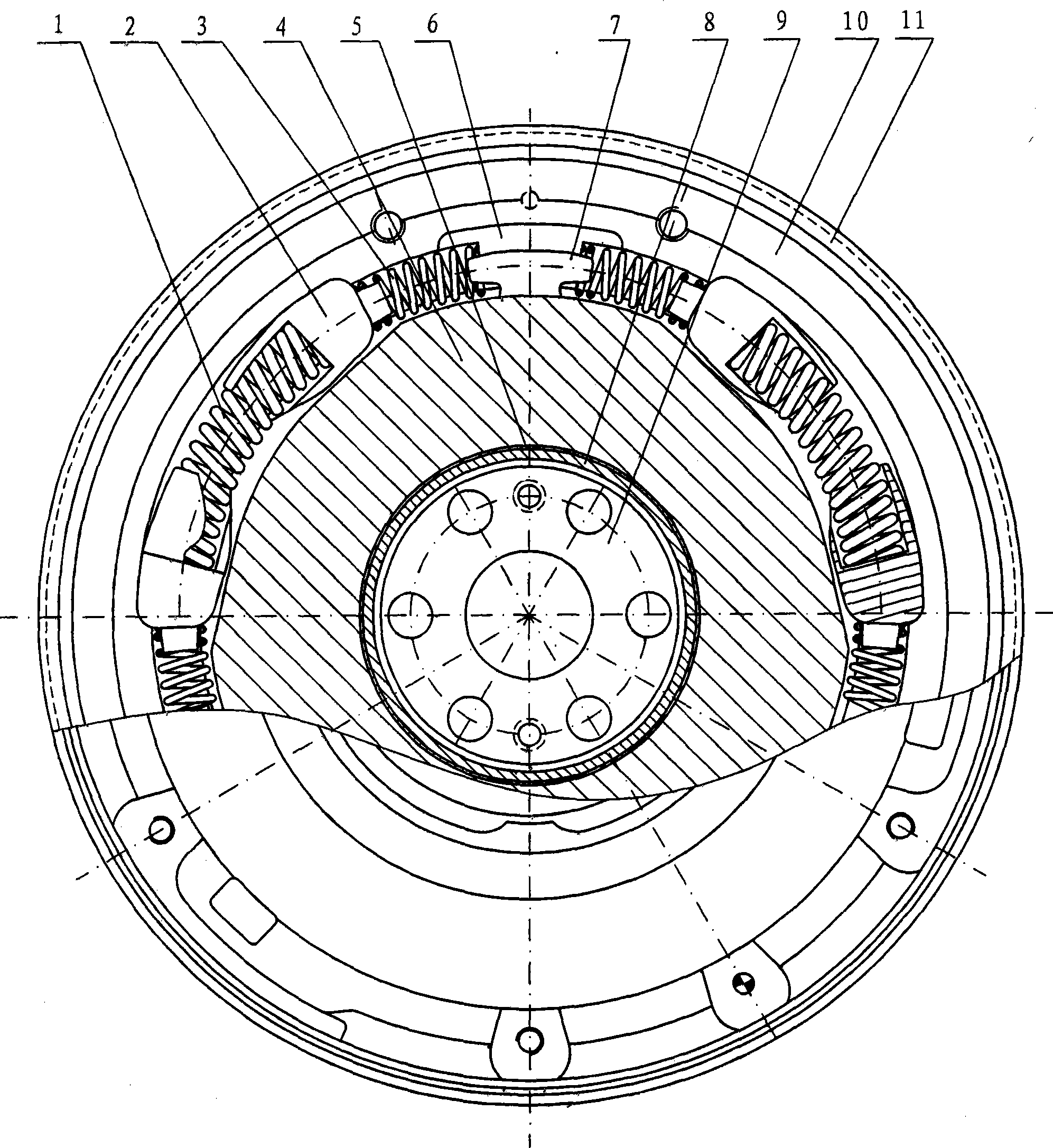

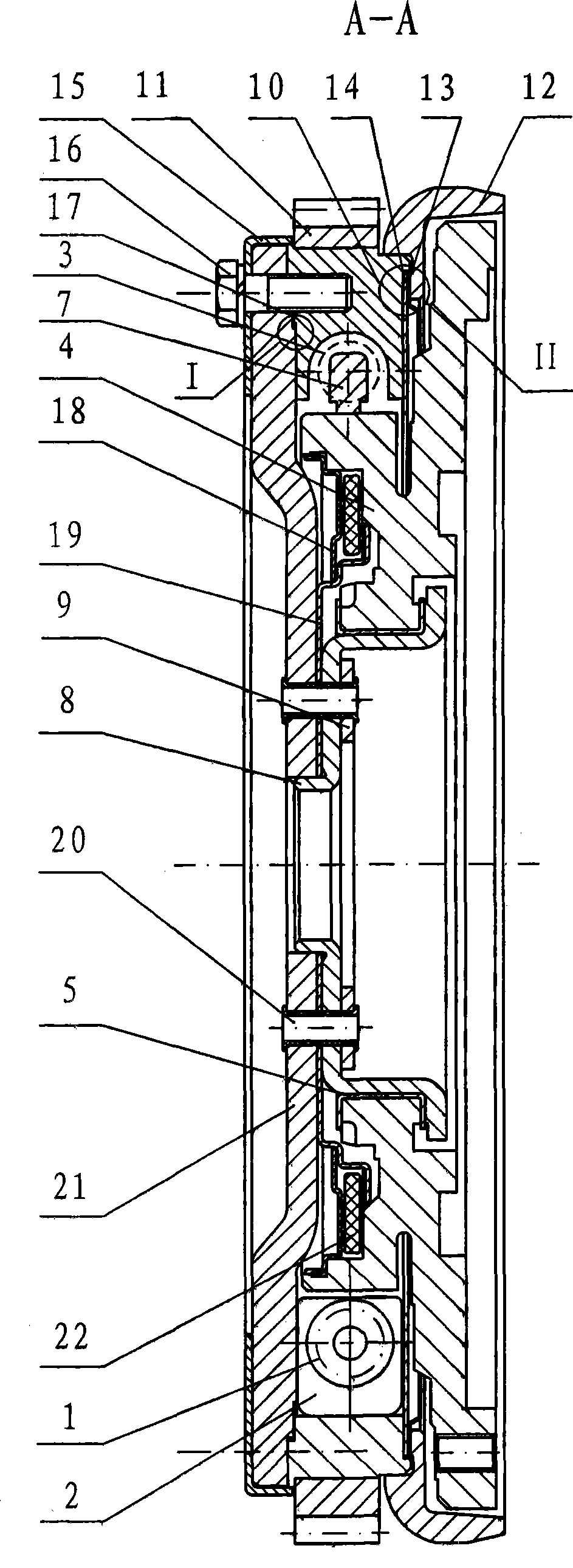

[0135] A 2.0L car engine uses a dual-stage friction dual-mass flywheel. The dual-mass flywheel includes a first spring 1, a spring seat 2, a second spring 3, a secondary flywheel 4, a washer 5, a pressure block 6, a shift block 7, and an end Cover 8, cushion block 9, primary flywheel 10, starting ring gear 11, ferrule 12, right ring 13, left ring 14, pressure plate 15, gasket 17, backing ring 18, connection plate 19, pin sleeve 20, cover plate 21 and ring block 22. Three central angles α are evenly distributed on the inner wall of the axial circular through hole of the primary flywheel 10 10 Both are 56°, inner radius R 10 The first annular bosses are all 100mm, and each of the three first annular bosses has a central angle α in the middle of the surface 11 is 28°, inner and outer radius R 11 , R 12 100mm and 116mm annular grooves respectively, the radial sections of the annular through grooves whose inner openings in the three first annular bosses are all towards the cent...

Embodiment 2

[0144] 2.3L—2.4L car engine with two-stage friction dual-mass flywheel, the dual-mass flywheel includes a first spring 1, a spring seat 2, a second spring 3, a secondary flywheel 4, a washer 5, a pressing block 6, and a shifting block 7. End cover 8, pad 9, primary flywheel 10, starting ring gear 11, ferrule 12, right ring 13, left ring 14, pressure plate 15, gasket 17, backing ring 18, connecting plate 19, pin sleeve 20, Cover plate 21 and ring block 22 . Three central angles α are evenly distributed on the inner wall of the axial circular through hole of the primary flywheel 10 10 Both are 56°, inner radius R 10 The first annular bosses are all 100mm, and each of the three first annular bosses has a central angle α in the middle of the surface 11 is 28°, inner and outer radius R 11 , R 12 100mm and 116mm annular grooves respectively, the radial sections of the annular through grooves whose inner openings in the three first annular bosses are all towards the center of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Shear modulus of elasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com