Column gear ellipsoid gear planetary system transplanting mechanism

A planetary system and elliptical gear technology, which is applied in the field of cylindrical tooth elliptical tooth planetary system insertion mechanism, can solve the problems of reducing the use range, and achieve the effects of reducing seedling damage, small impact, and reducing the radius of gyration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

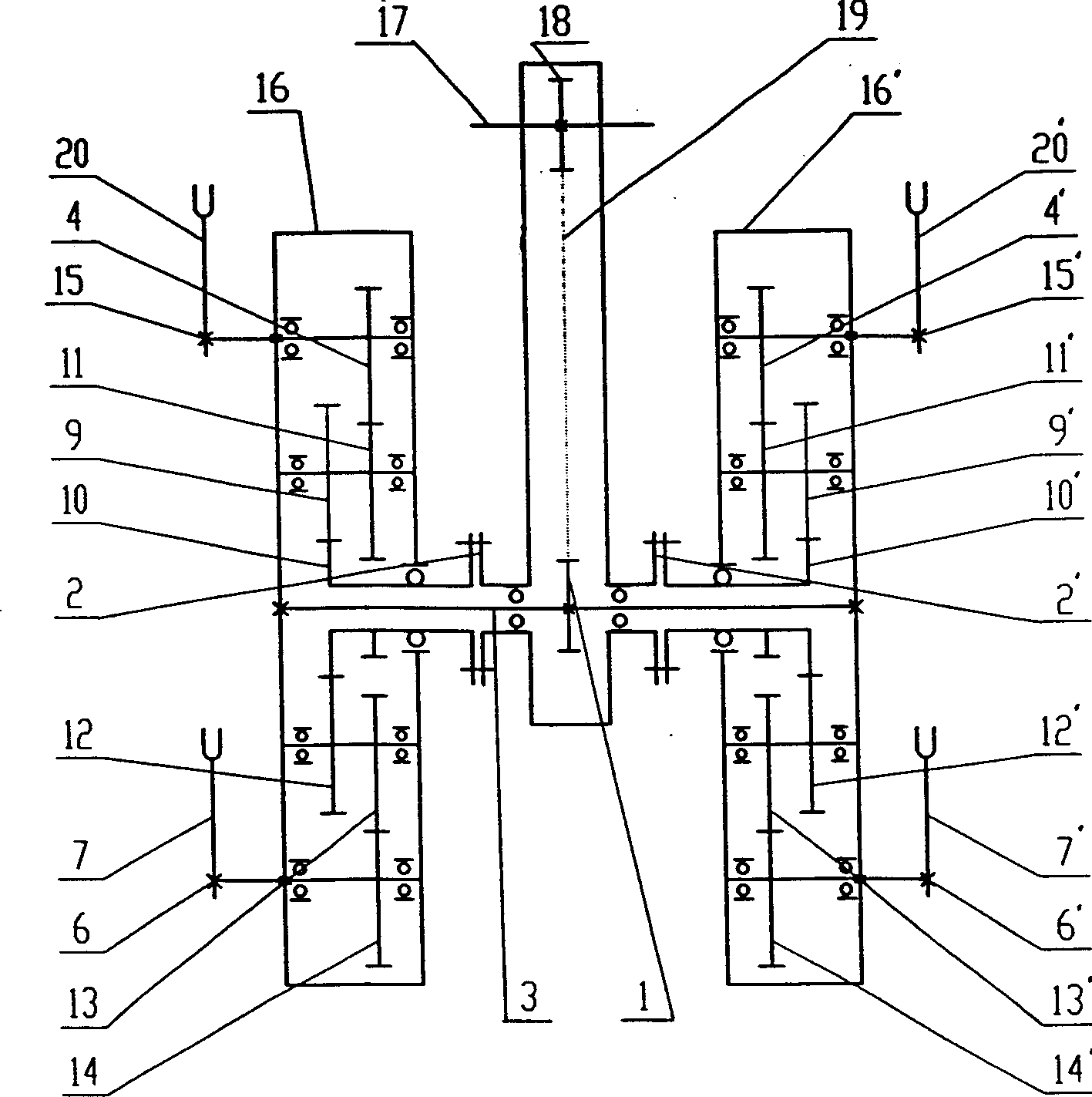

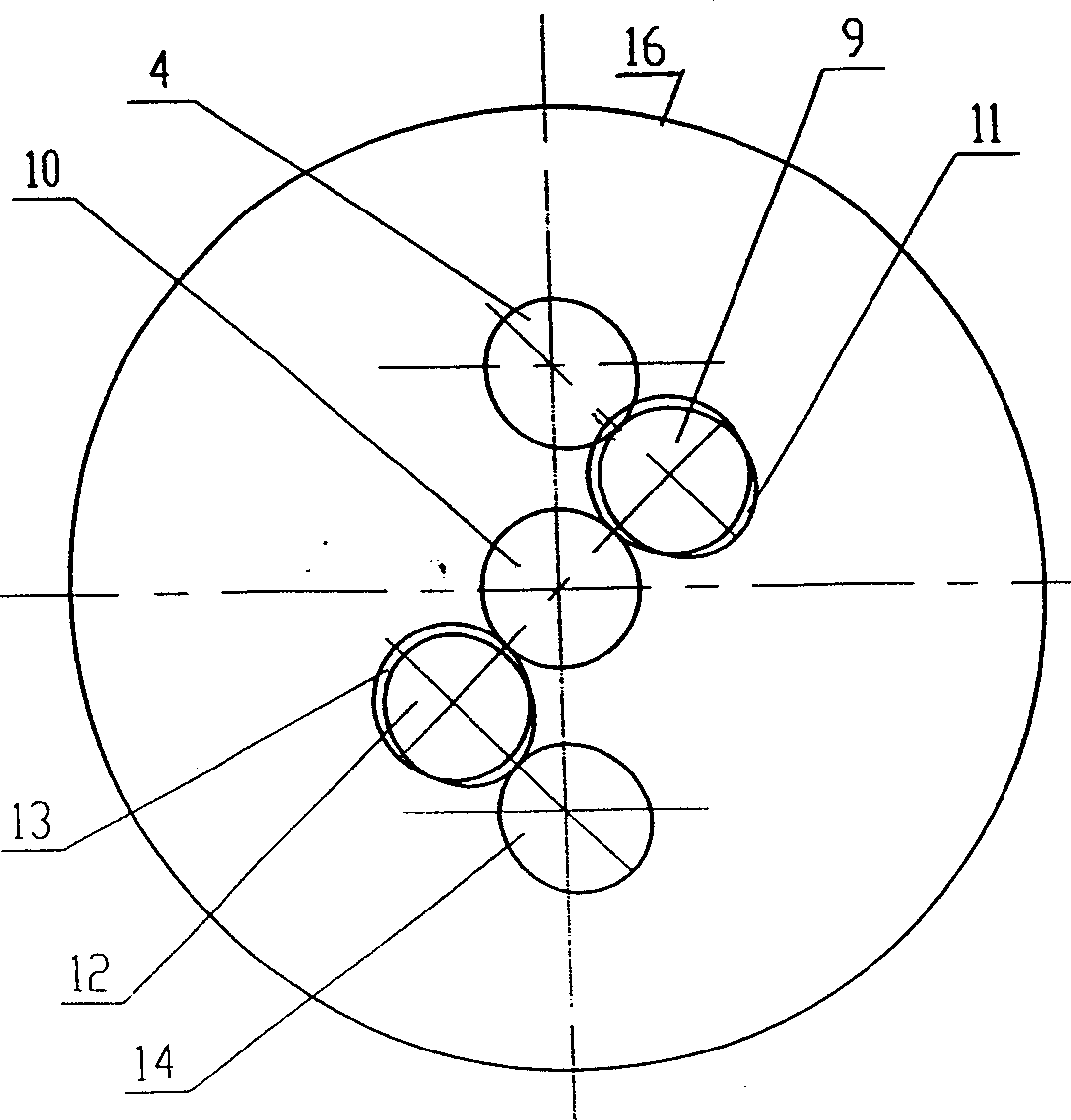

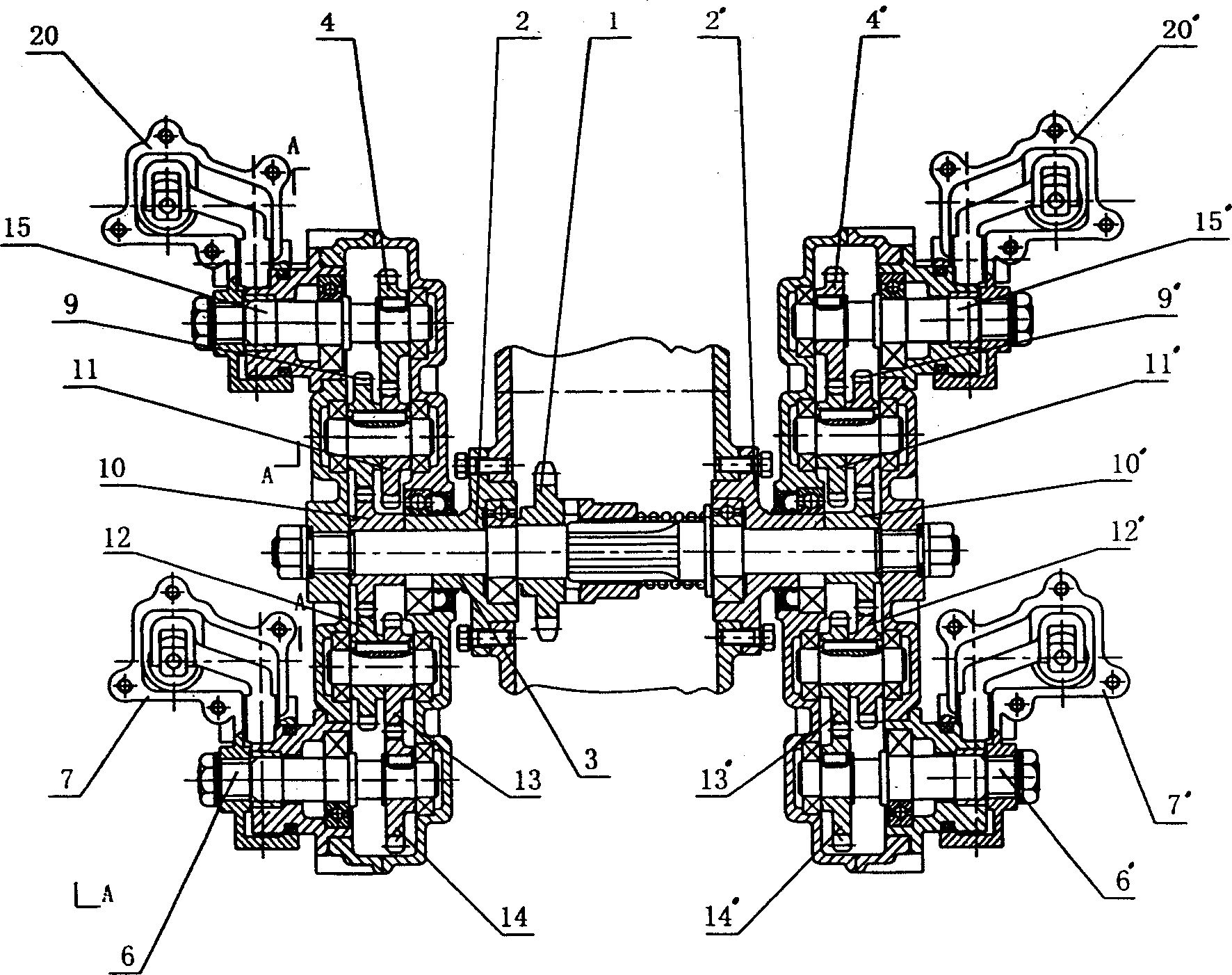

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the spur-toothed elliptical gear planetary system insertion mechanism of the present invention includes a transmission component and a planting arm component. The transmission parts include a driving sprocket 18 mounted on the transmission shaft 17 in the sprocket box, which is connected with the central sprocket 1 mounted on the central shaft 3 through a chain 19. The left and right sides of the sprocket box are respectively equipped with a gear box 16, 16', gear boxes 16, 16' are equipped with central cylindrical gears 10, 10' on both sides of the central shaft 3, and the two ends of the central shaft 3 respectively use splines to drive the gear boxes 16, 16' to rotate, and the central cylindrical gears at both ends 10,10' are respectively fixed on the sprocket case by flanges 2,2'. The two sides of the central cylindrical gear 10, 10' in the left and right gear boxes 16, 16' are respectively symmetrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com