High-power semiconductor fiber-coupled laser and coupling method thereof

A fiber coupling and semiconductor technology, applied in the field of lasers, can solve the problems of multi-die coupling technology processing accuracy limitation, increased weight and material consumption, and limited number of coupling dies. It is easy to guarantee the processing accuracy, reduce packaging components, and structure Simple and lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

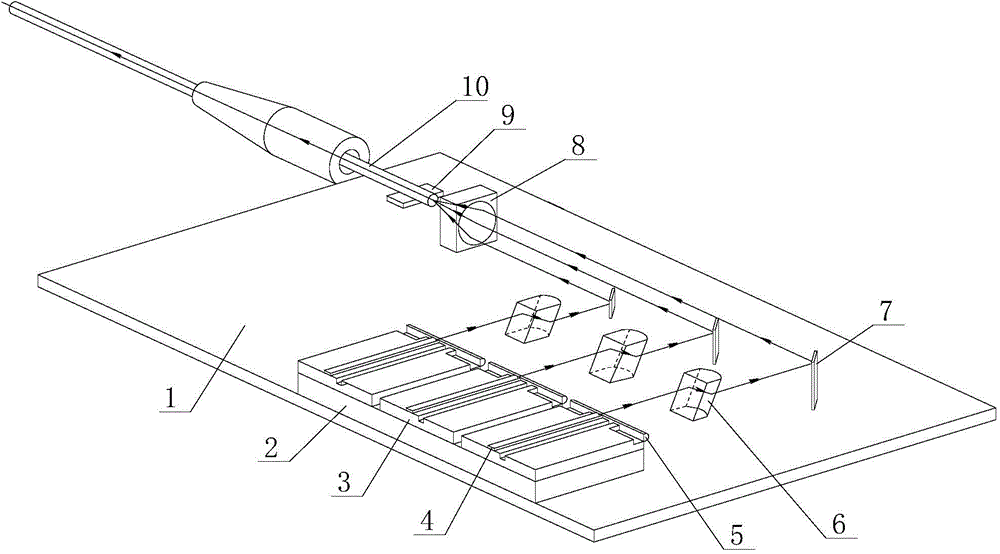

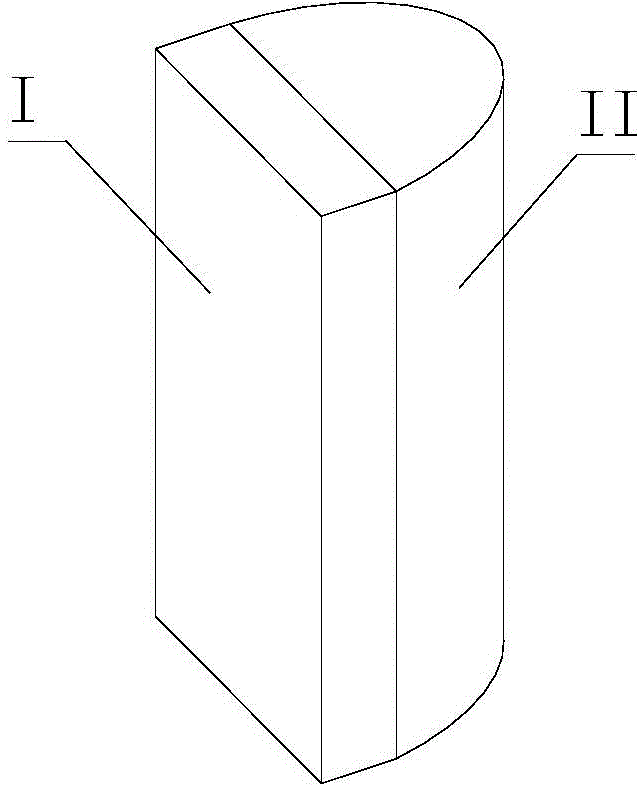

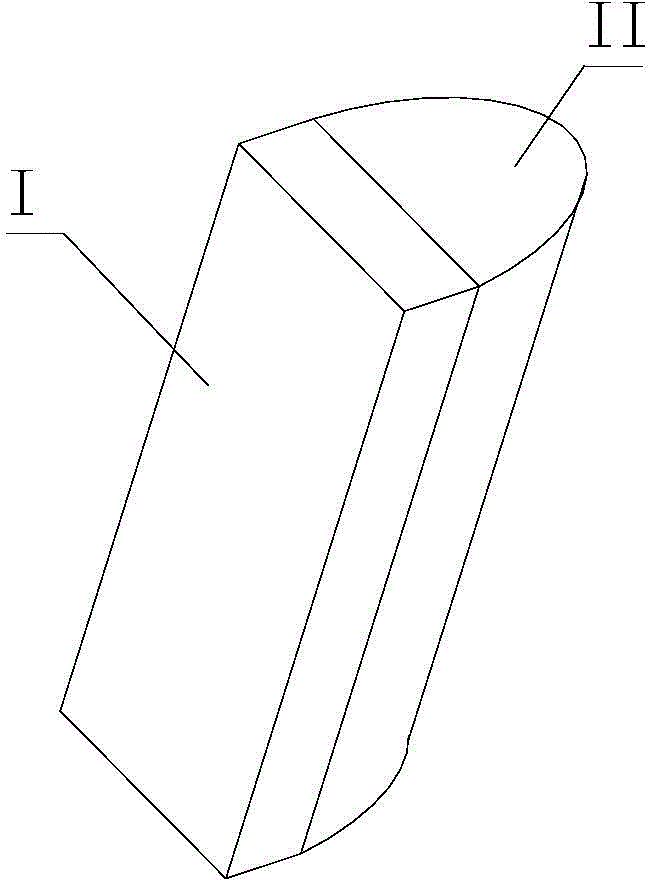

[0024] See figure 1 , is a structural schematic diagram of the high-power semiconductor fiber-coupled laser of the present invention, a high-power semiconductor fiber-coupled laser of the present invention includes a plurality of one-to-one corresponding laser diodes 4 integrated on the base plate 1, and a fast-axis collimating mirror FAC 5. The slow axis collimating mirror SAC 6 and the reflector 7 also include a focusing lens 8 and an optical fiber 10. The laser diode 4 is horizontally arranged at the same height, and its front end is provided with a fast axis collimating mirror FAC 5; the slow axis collimating mirror The SAC 6 is directly arranged on the base plate 1, and is a plano-convex lens inclined as a whole, and the thickness of each slow-axis collimator SAC 6 decreases successively along the distance from the focusing lens 8 from near t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com