Method for optimizing cycloid gear tooth outline modification amount based on matlab

A cycloidal gear tooth and optimization method technology, which is applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as loss of solution and easy occurrence of virtual solutions, improve transmission efficiency, ensure stability, overcome The effect of empirical trial and error verification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

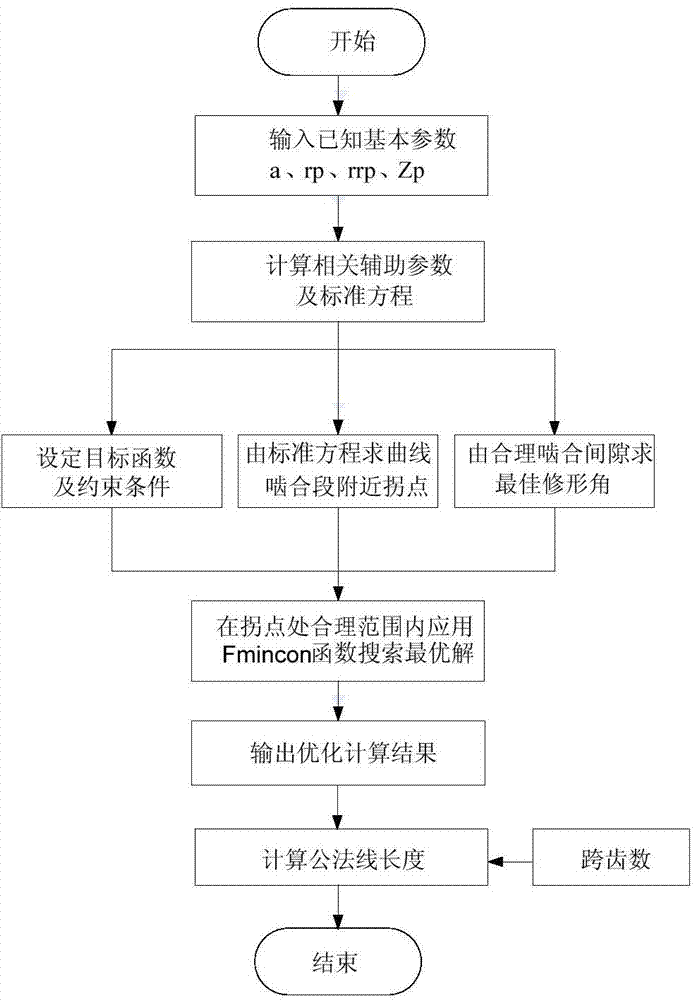

[0037] see figure 1 , a method for optimizing the modification amount of cycloid gear tooth profile based on matlab, including the following steps:

[0038] Step 1. Calculate the position of the inflection point of the tooth profile of the cycloidal gear according to the basic parameters of the cycloidal gear; the specific process is:

[0039] First select the basic parameters of the cycloidal wheel, said basic parameters include: cycloidal wheel tooth number zc, pin wheel tooth number zp, eccentricity a, pin tooth center garden radius rp, pin tooth sleeve outer circle radius rrp;

[0040] Then calculate the position of cycloid wheel inflection point; Described inflection point is the concave and convex boundary point of curve; The concrete ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com