Double-drive coaxial forward and reverse output spiral rock-entering drilling machine

A forward-reverse, double-drive technology, which is applied to rotary drilling rigs, rotary drilling, and driving devices for drilling in boreholes, can solve problems such as difficult installation, difficult maintenance, and large external dimensions, and achieve The effect of good hole forming quality, no mud pollution, and low installation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

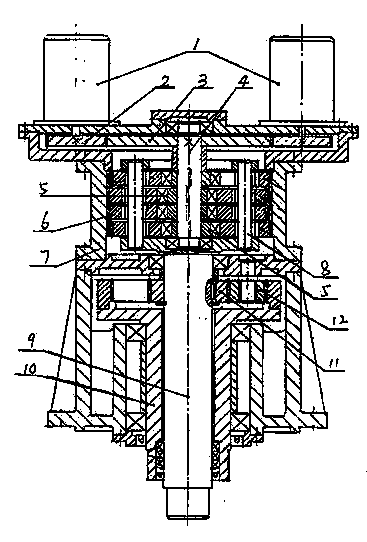

[0017] As shown in the figure, a double-drive coaxial forward and reverse output helical rock drilling rig includes a double-input motor, a small gear 2, a large gear 3, an input shaft 4, an eccentric bearing 5, a cycloidal wheel 6, a casing 7, a column Pin 8, output shaft 9, outer sleeve 10, center wheel 11 and planetary wheels 12. The double-input motors are respectively connected to a pinion 2, and the pinion 2 meshes with the large gear 3 arranged on the input shaft 4 through both sides, and the input shaft 4 is respectively connected to the four sets of cycloid wheels through four bearing eccentric bearings 5. The central hole is connected in series, and the outer circle of the cycloidal wheel 6 is provided with external teeth, and the external teeth mesh with the inner ring gear of the casing 7. The cycloidal wheel 6 is also provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com