Hollow type gear transmission speed reducer

A technology of gear transmission and deceleration device, applied in the direction of gear transmission device, transmission device, transmission device parts, etc., can solve the problems of messy transmission device, easy damage of wiring and piping, etc., and achieves low processing difficulty, low production cost, transmission good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

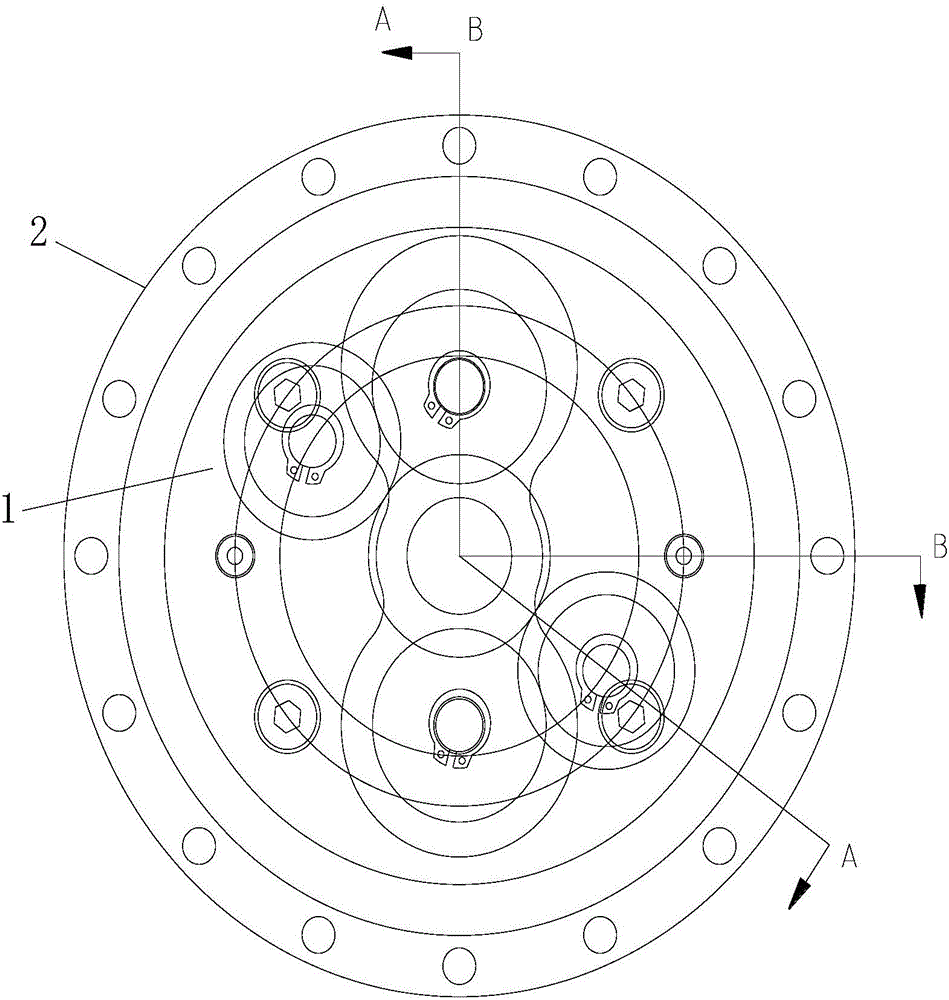

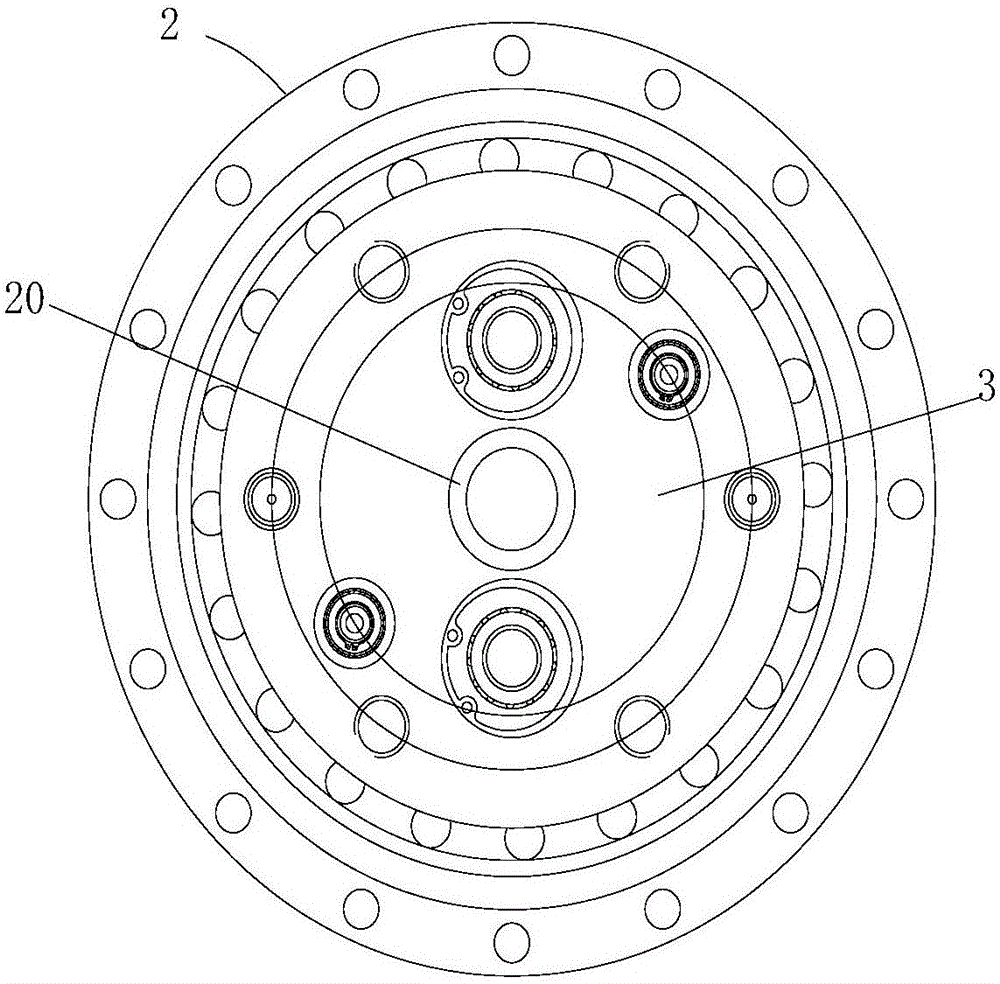

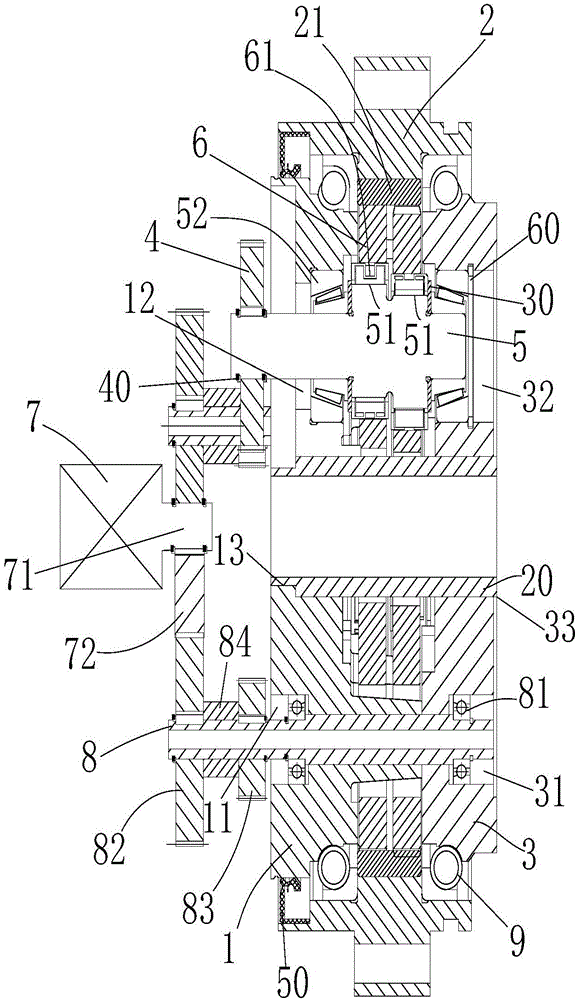

[0030] refer to Figure 1-Figure 4 , this embodiment provides a hollow gear transmission reduction device, including an output disc 1, a pin gear housing 2, a support flange 3, a planetary wheel 4, a crank shaft 5, a cycloidal wheel 6, a motor 7 and a rotating shaft 8;

[0031] The output disc 1 and the supporting flange 3 are respectively installed at the openings at both ends of the pinion housing 2, and the output disc 1 and the supporting flange 3 are fixedly connected by screws. A ferrule assembly 9 is provided between the output disk 1 and the pintooth housing 2, and a ferrule assembly 9 is provided between the support flange 3 and the pintooth housing 2; the ferrule assembly 9 is Angular contact ball bearings. The output disc 1 is provided with at least two left rotation shaft mounting holes 11 and at least two left crank shaft mounting holes 12 in the axial direction, and a left through hole 13 is provided in the middle of the output disc 1 in the axial direction; Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com