Method for shaping cycloidal gear tooth profile

A technology of cycloidal gear and cycloidal wheel, which is applied to gear teeth, components with teeth, belts/chains/gears, etc. It can solve the problems of designing the modification curve and achieving the optimal modification target, etc., and achieves strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

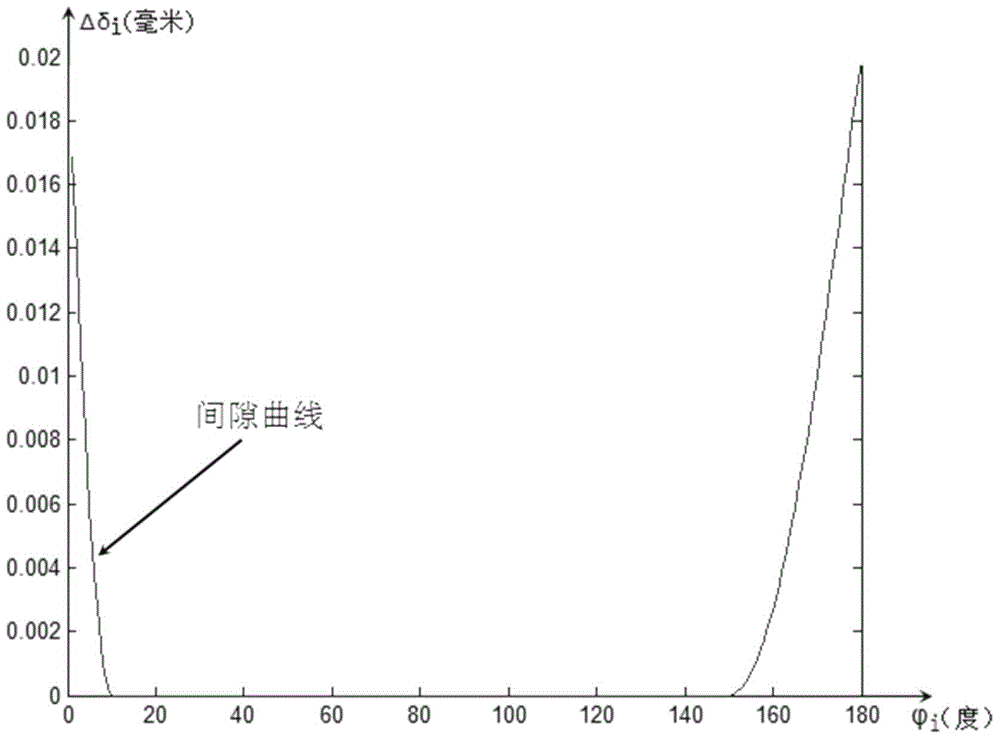

[0053] For modifications aimed at minimizing elastic deformation at the meshing points:

[0054] In formula (1), take Δl=0, θ 1 =10,θ 2 = 150, t = 0.02, The gap curve when figure 1 As shown, the incremental value of the arc radius of the modified grinding wheel can be calculated according to formula (6). At each meshing point, the incremental value of the arc radius of the grinding wheel is different, which is a curve similar to the clearance curve. Substituting the incremental value of the arc radius of the modified grinding wheel into the cycloid tooth profile equation, as shown in formula (7), the modified cycloid tooth profile can be obtained; Write the trimming program of the shaped grinding wheel on the machine, trim the shaped grinding wheel, and then grind and process the teeth of the cycloidal wheel.

[0055]

[0056] In formula (7), r p is the radius of the center circle of the pin tooth; r rp is the pin tooth (roller) radius; Δr rpi Incremental value of t...

Embodiment 2

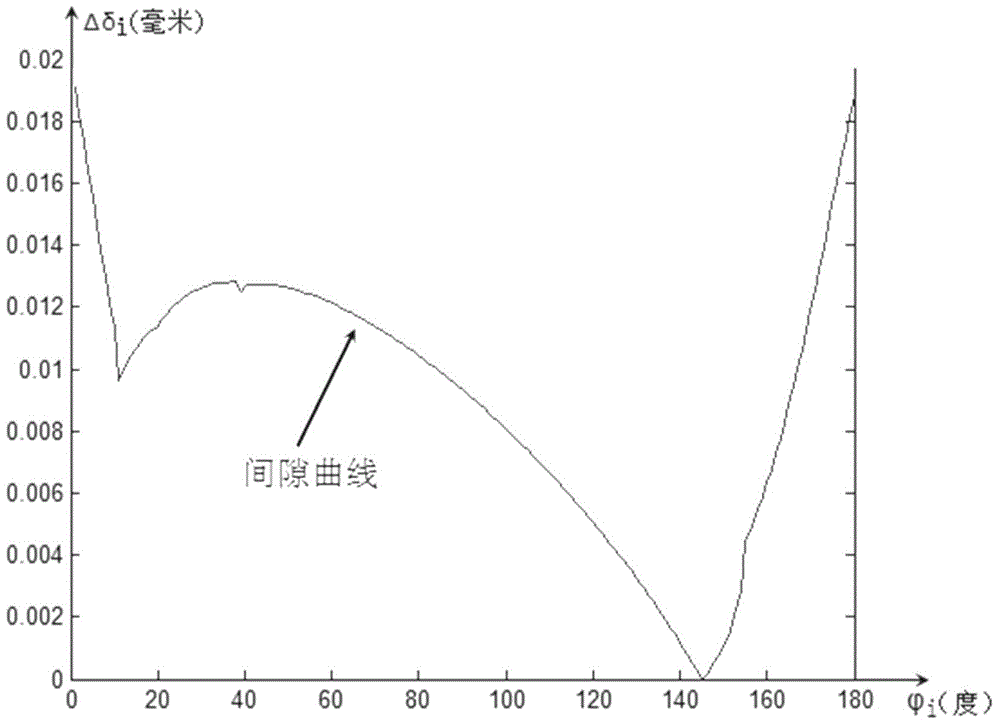

[0060] For the modification aiming at the minimum transfer error:

[0061] In formula (3), take θ 1 =10,θ 3 =20,θ 4 =145,θ 2 =155, T=1000NM, The gap curve when figure 2 shown, where:

[0062]

[0063] r c 'is the radius of the pitch circle of the cycloid wheel.

Embodiment 3

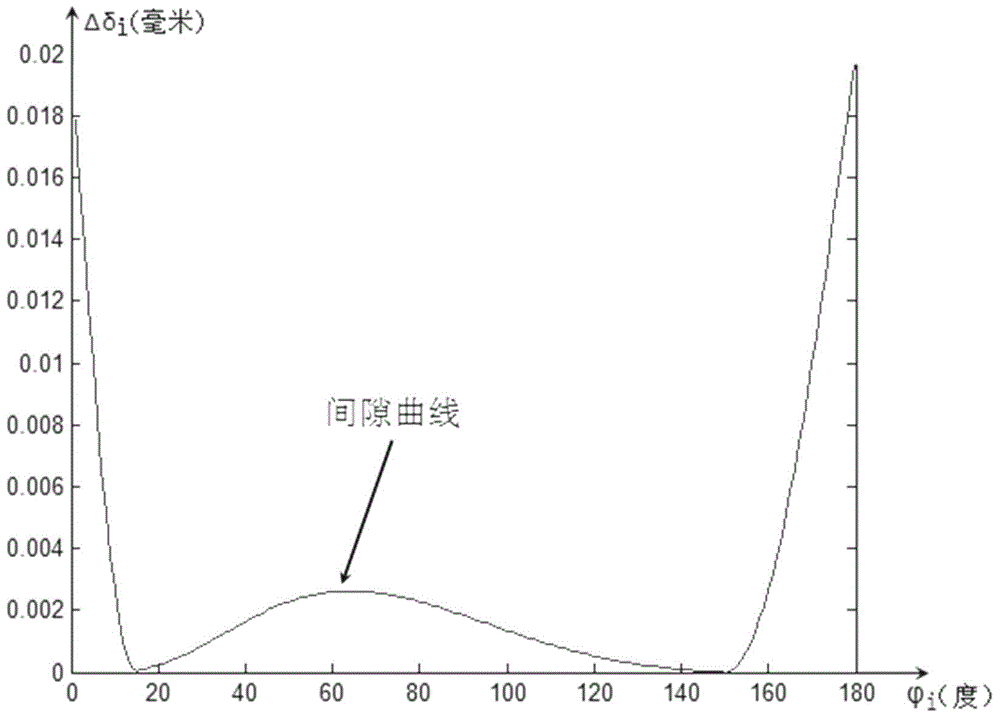

[0065] For modifications aimed at minimizing contact stress:

[0066] In formula (5), take a=1.04, b=0.75, θ 1 =15, θ 2 =150, t=0.02, k=0.4, n=4, The gap curve when image 3 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com