Precise planetary cycloid reducer

A technology of cycloidal reducer and planet, which is applied in the direction of transmission parts, gear transmission, belt/chain/gear, etc., can solve the problems of high manufacturing cost and difficult processing, and achieve reasonable structure and low difficulty in modification process , high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

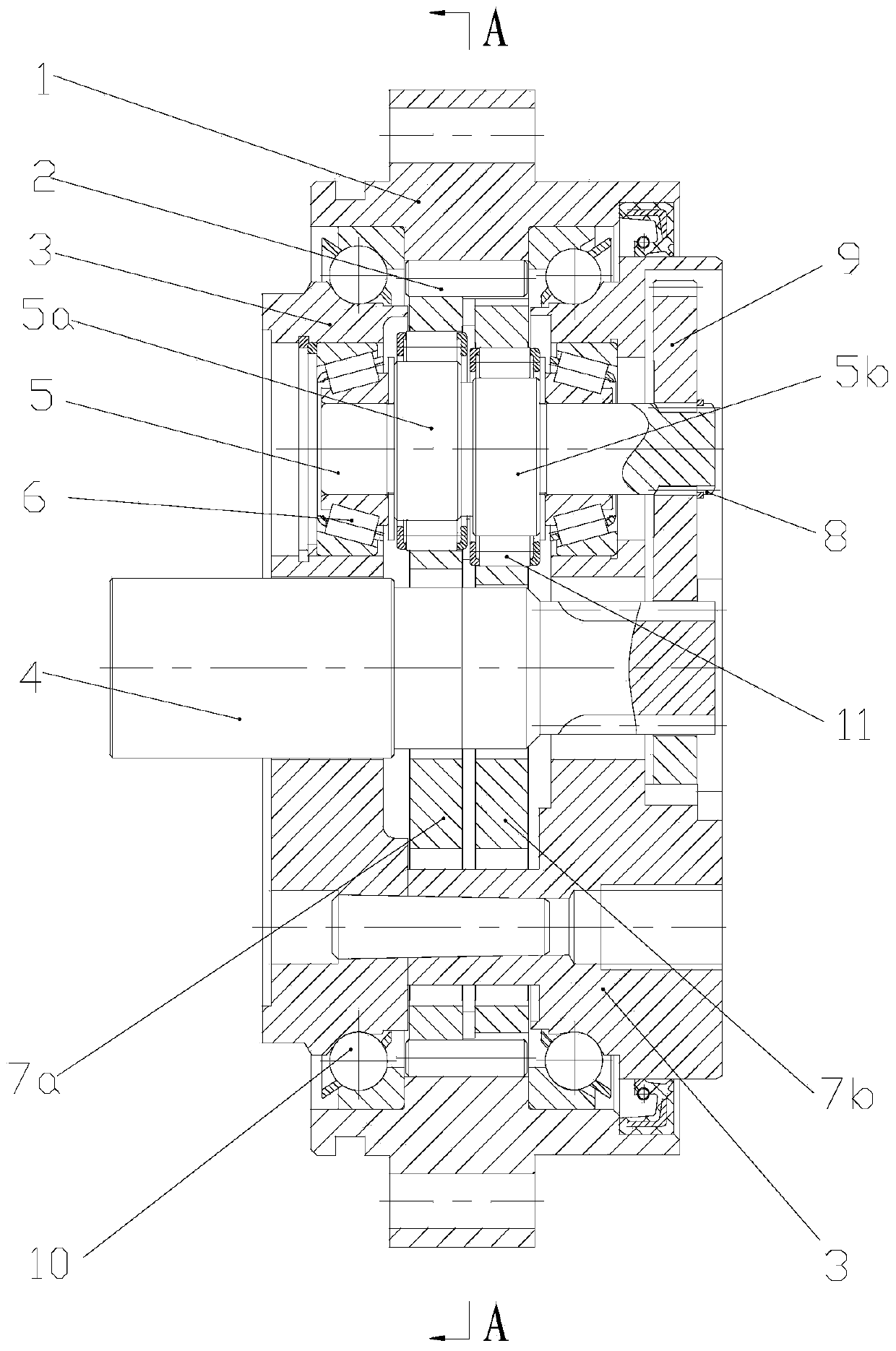

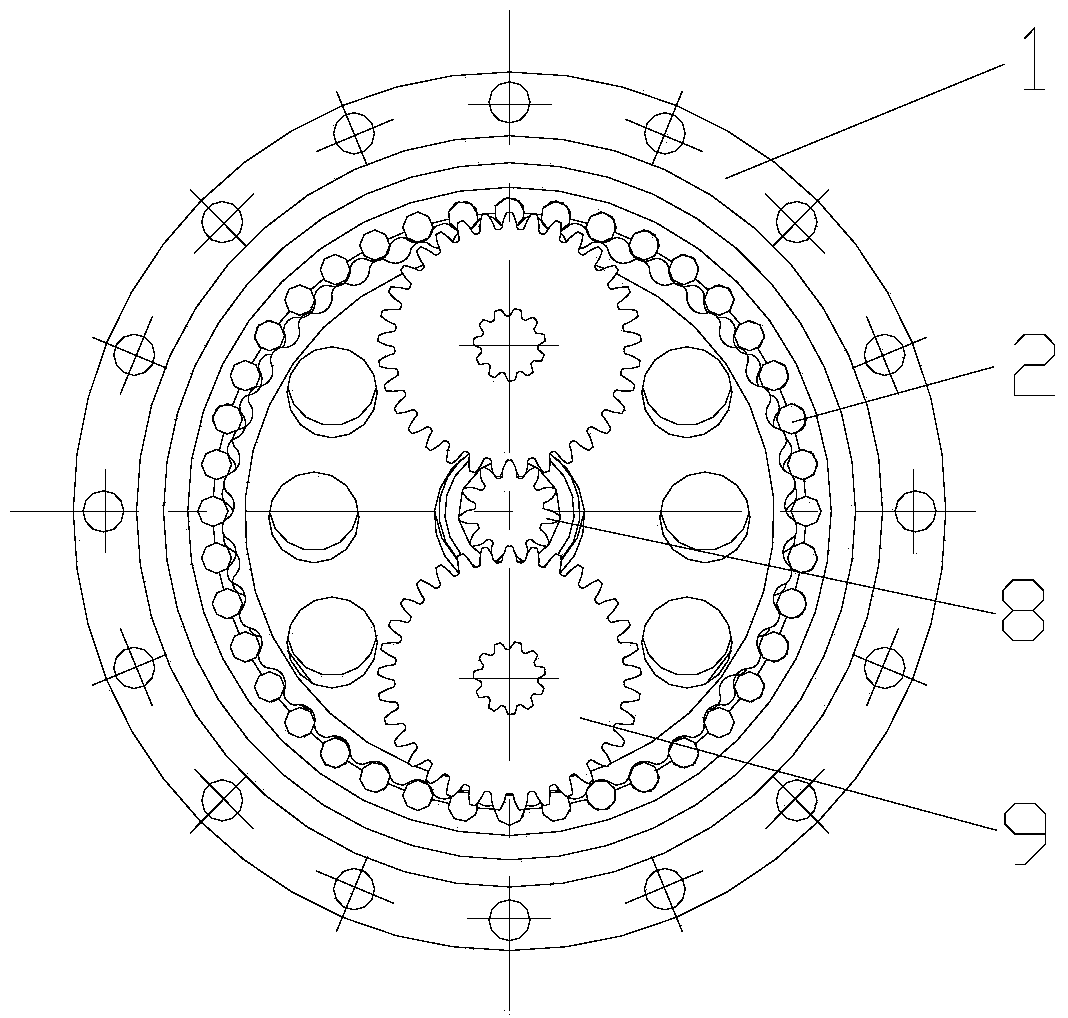

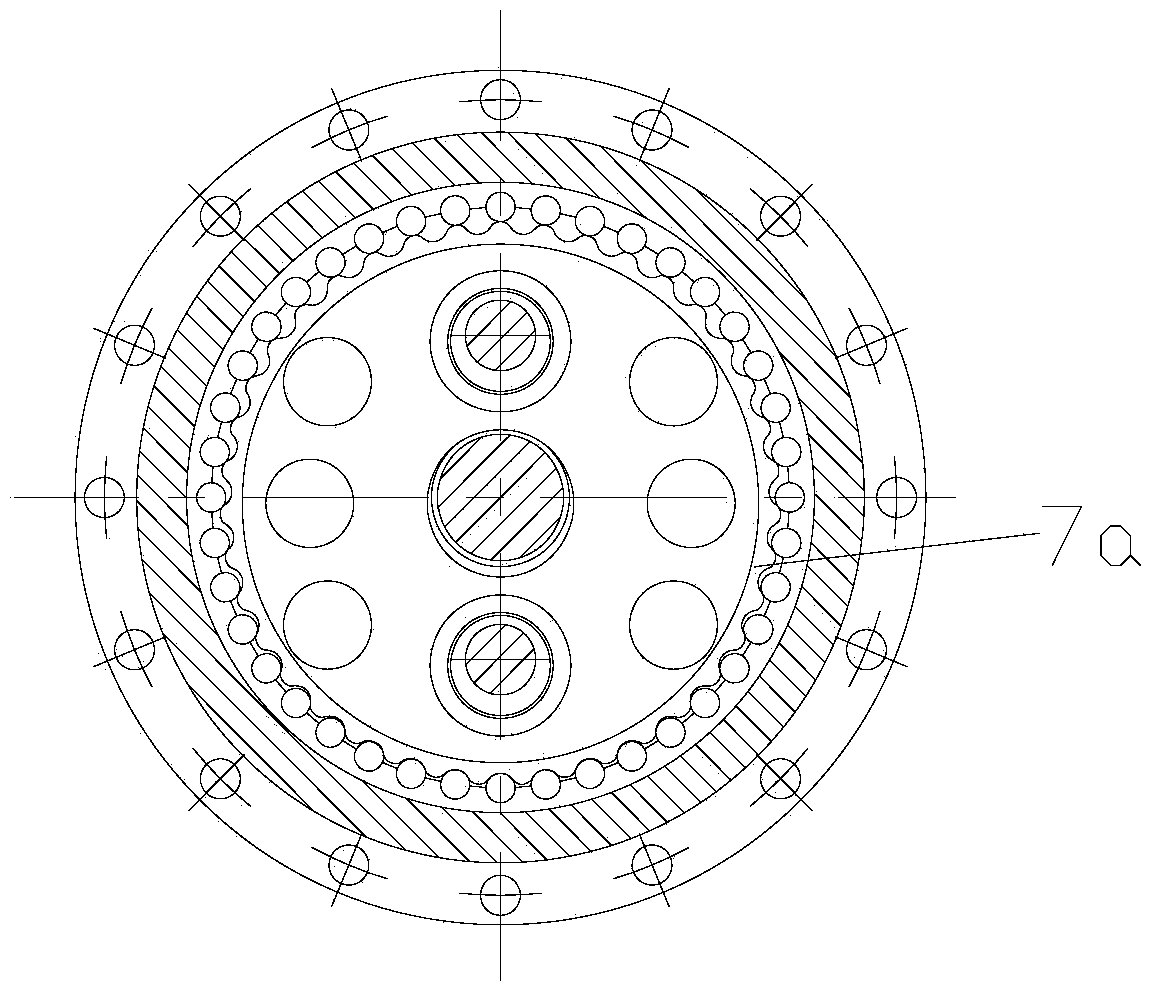

[0036] A precision planetary cycloidal reducer, including a central shaft (equipped with a central gear), an eccentric shaft, a planetary gear (fixed on the eccentric shaft), a cycloidal wheel, pin teeth, a pin gear housing and an output planet carrier, etc. .

[0037] In this precision planetary cycloid reducer, the central gear of the central shaft meshes with a group (2 or 4) of evenly distributed planetary gears at the same time; the planetary gears are fixedly connected to the eccentric shaft, and the eccentric part of the eccentric shaft is rotatable through the bearing Support two cycloidal wheels; the phase difference of the two cycloidal wheels is 180°, and the tooth profile of the cycloidal wheel is not a standard equidistant curve of a short epicycloid, but modified by turning angle and equidistant Optimizing the tooth shape: the optimized amount of modification in this embodiment is 0.003° of corner modification plus 0.006 mm of equidistant modification.

[0038] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com