Hydraulic mechanical type automatic gear shifting system

A technology of automatic shifting and hydraulic machinery, which is applied in the direction of mechanical equipment, transmission device control, and components with teeth, etc., can solve the problems of complex planetary transmission mechanism, difficult start control, AMT shifting impact, etc., and achieve processing Good manufacturability, overcoming poor fuel economy and quick response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention is described in detail below in conjunction with accompanying drawing:

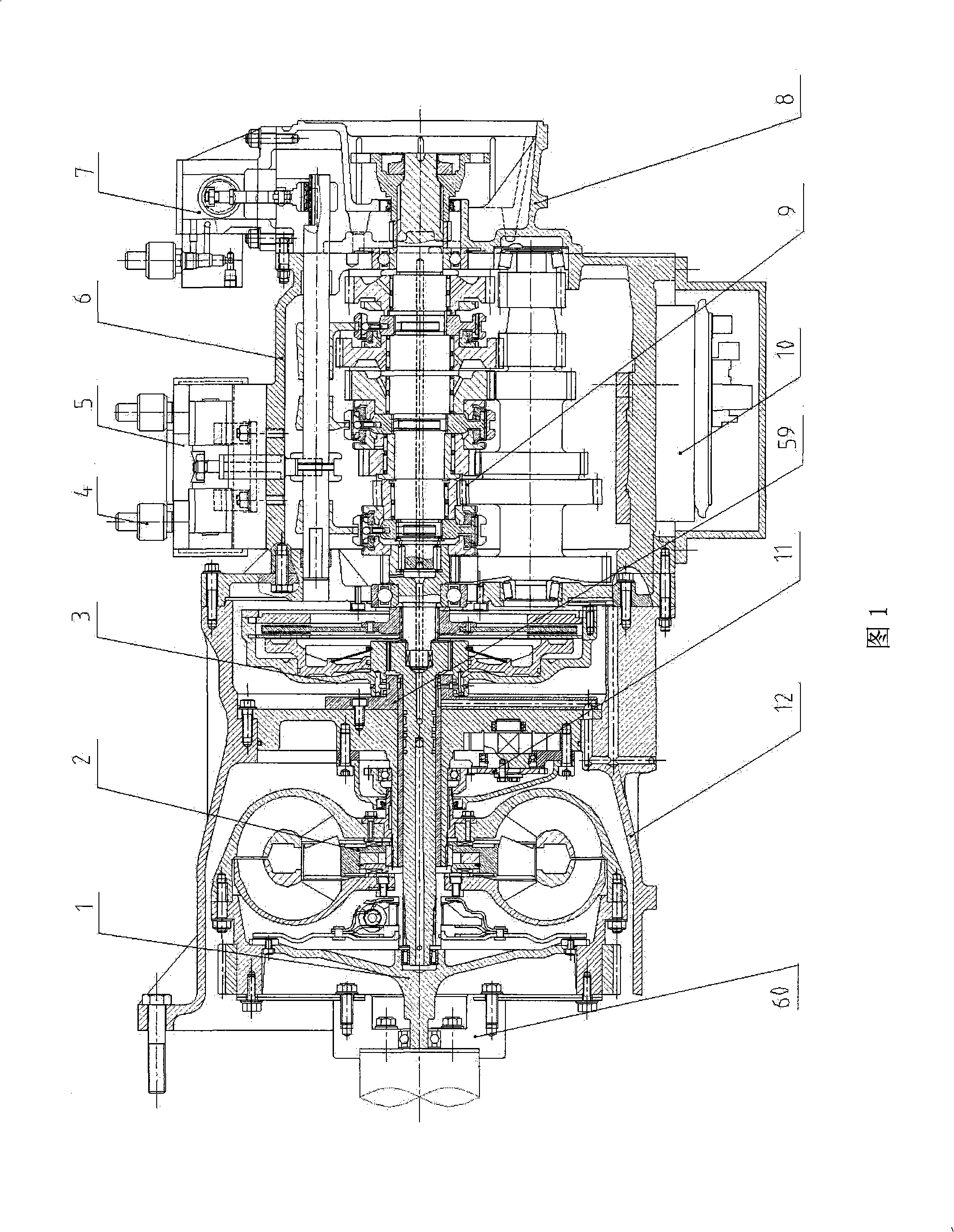

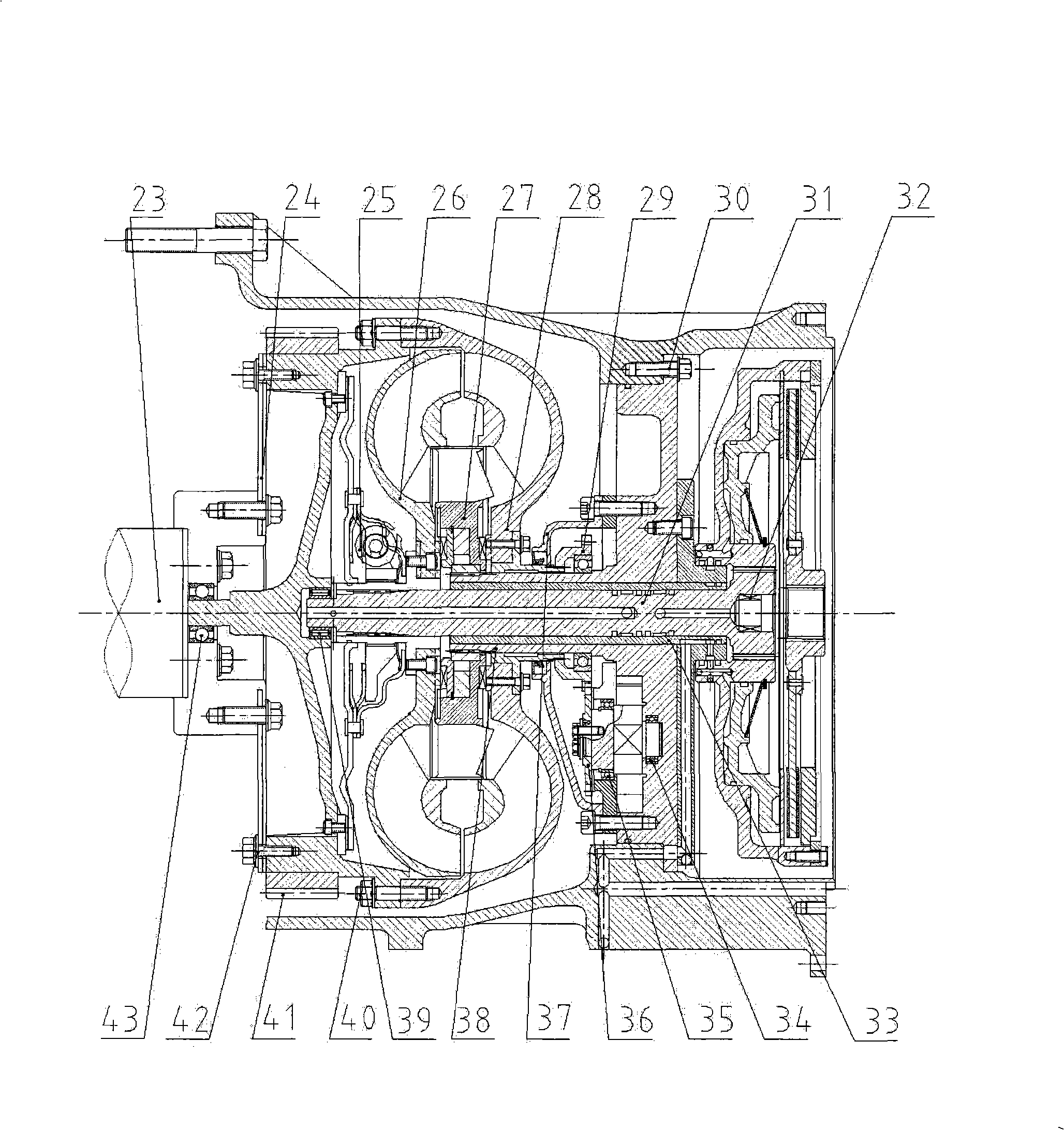

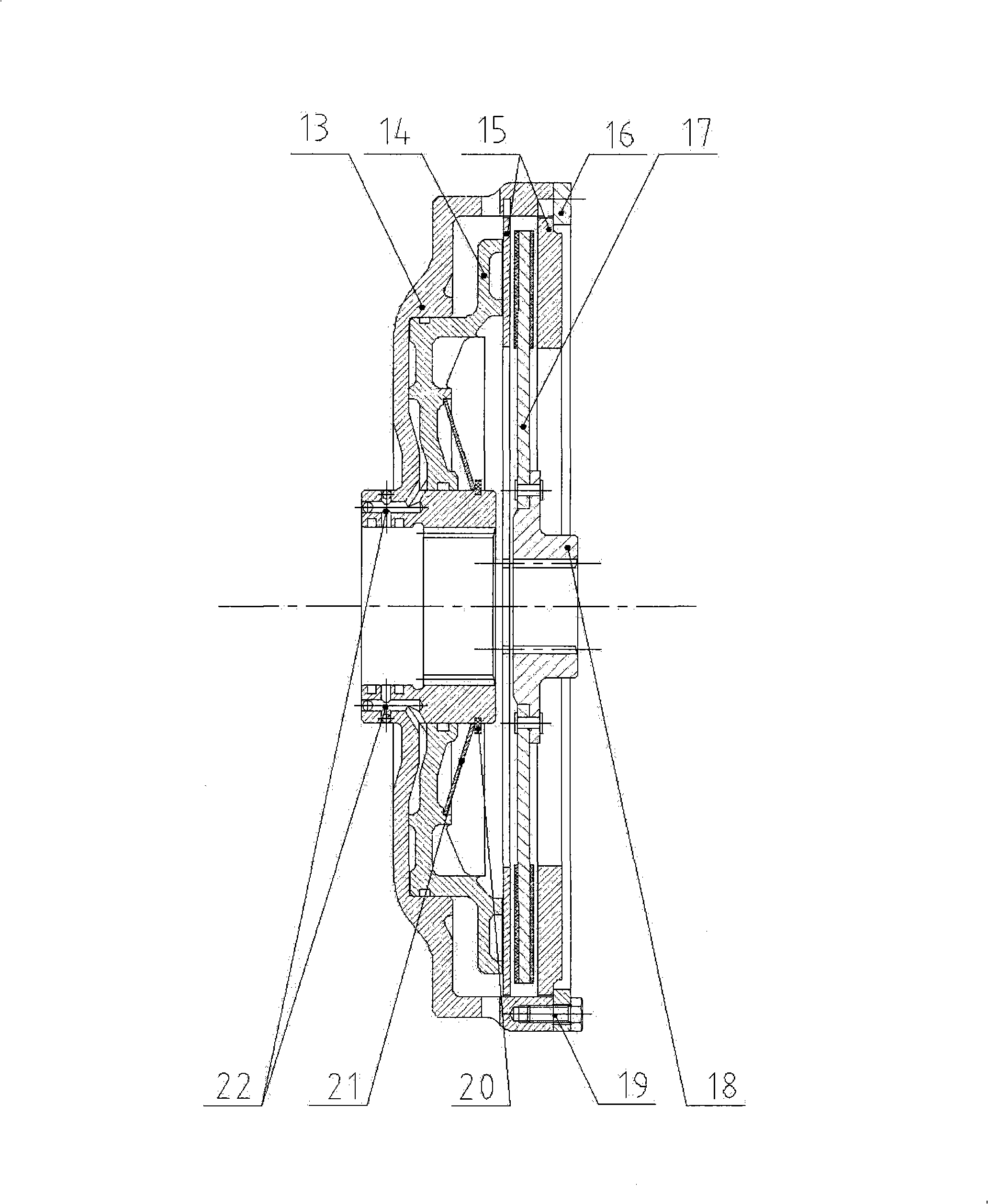

[0056] See Figure 1 to Figure 4 , The hydromechanical automatic shifting system is composed of two parts, the mechanical structure and the automatic control system.

[0057] The mechanical structure part includes a hydraulic torque converter assembly 2, a wet shift main clutch 3, a shift actuator assembly 5, a gear selection actuator assembly 7, a multi-gear parallel shaft gearbox 9, Parts such as front box body 12 and lock-up clutch 25.

[0058] The hydraulic torque converter assembly 2 is composed of the pump wheel cover 1 and the hydraulic torque converter Q. The front box body 12 is an integral box body part, and components such as the pump wheel cover 1, the hydraulic torque converter Q, the wet shift main clutch 3, the cycloid internal gear pump 11 and the lock-up clutch 25 are all installed on its Inside, the degree of integration is high, and it becomes the front b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com