Integrated high-speed cycloidal wheel hub motor

A cycloid wheel, integrated technology, applied in the field of drive device and integrated high-speed cycloid in-wheel motor, can solve the problems of increasing the size of the in-wheel motor and sacrificing space, and achieve the effect of compact structure, reducing excessive size and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

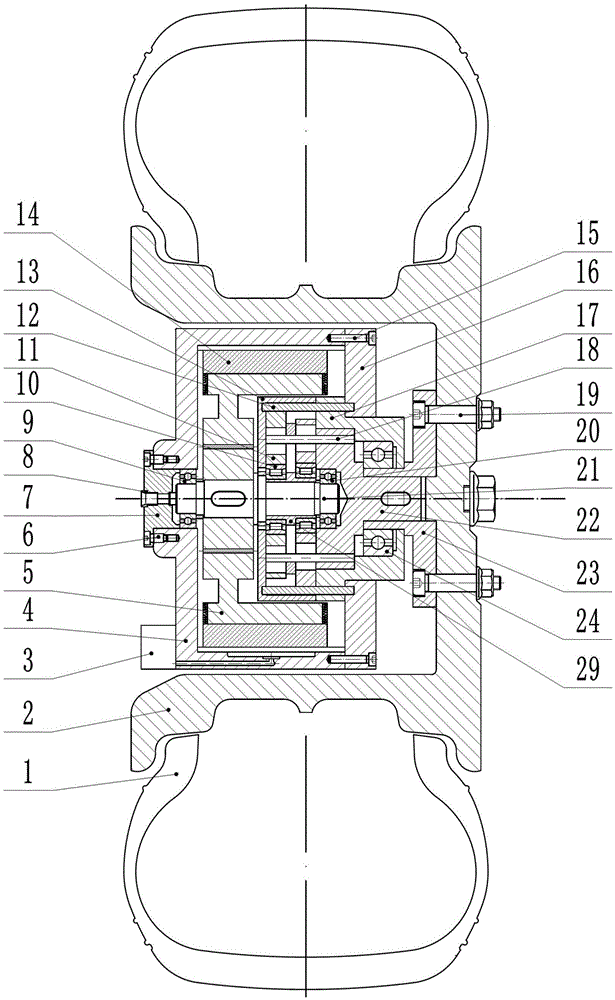

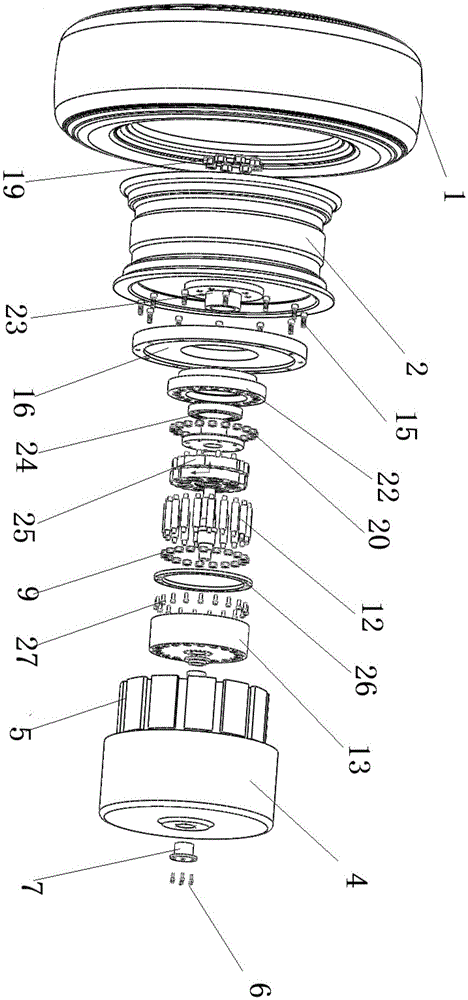

[0021] The present invention will be further described below in conjunction with accompanying drawing.

[0022] Such as Figure 1-4 As shown, this embodiment provides an integrated high-speed cycloidal hub motor, including a hub component 30, a motor component 28, a cycloid reducer component, and an output component. The hub component includes a tire 1 and a hub 2, and the two are closely attached , exercise together. The motor parts are installed in the concave space of the wheel hub 2, and the motor parts include the motor casing 4 close to the car body, the motor inner casing 16, the central shaft 21, the rotor 5 connected to the central shaft 21 by a key, and the rotor The stator 14 with 5 phases is provided with a central hole on the motor casing 4, and an external connection block 7 is connected to the central hole on the motor casing 4 through a fastening screw 6, and an oil interface 8 is provided on the external connection block 7. An oil circuit and an oil-cooled m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com