Gear motor for seat regulating means

A technology of adjusting device and gear motor, applied in electromechanical devices, vehicle seats, transmission devices, etc., can solve the problems of low transmission efficiency of gear motor, low bearing capacity of gear box, low transmission efficiency, etc., and achieve high bearing capacity, strong The effect of load capacity and strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

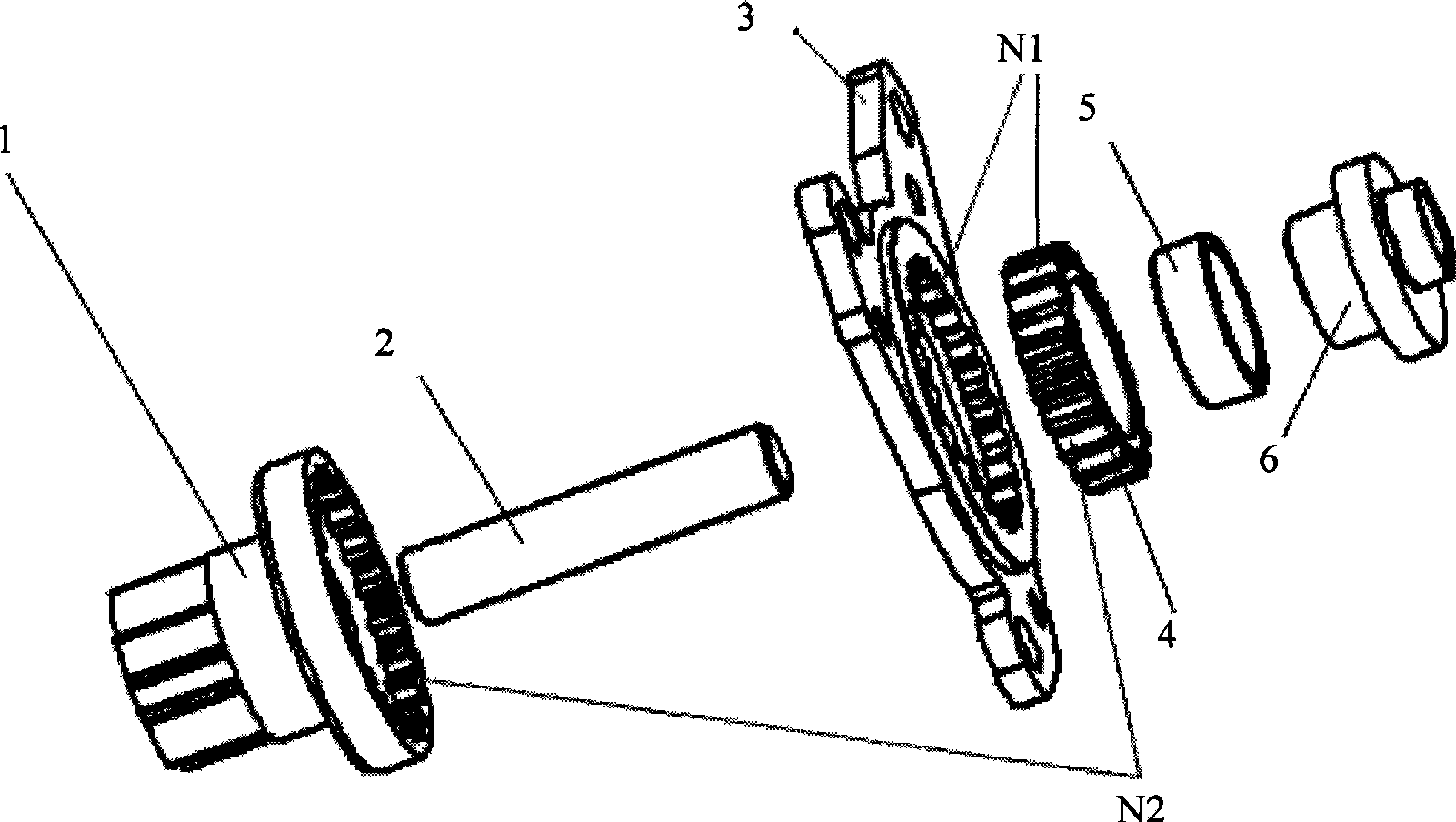

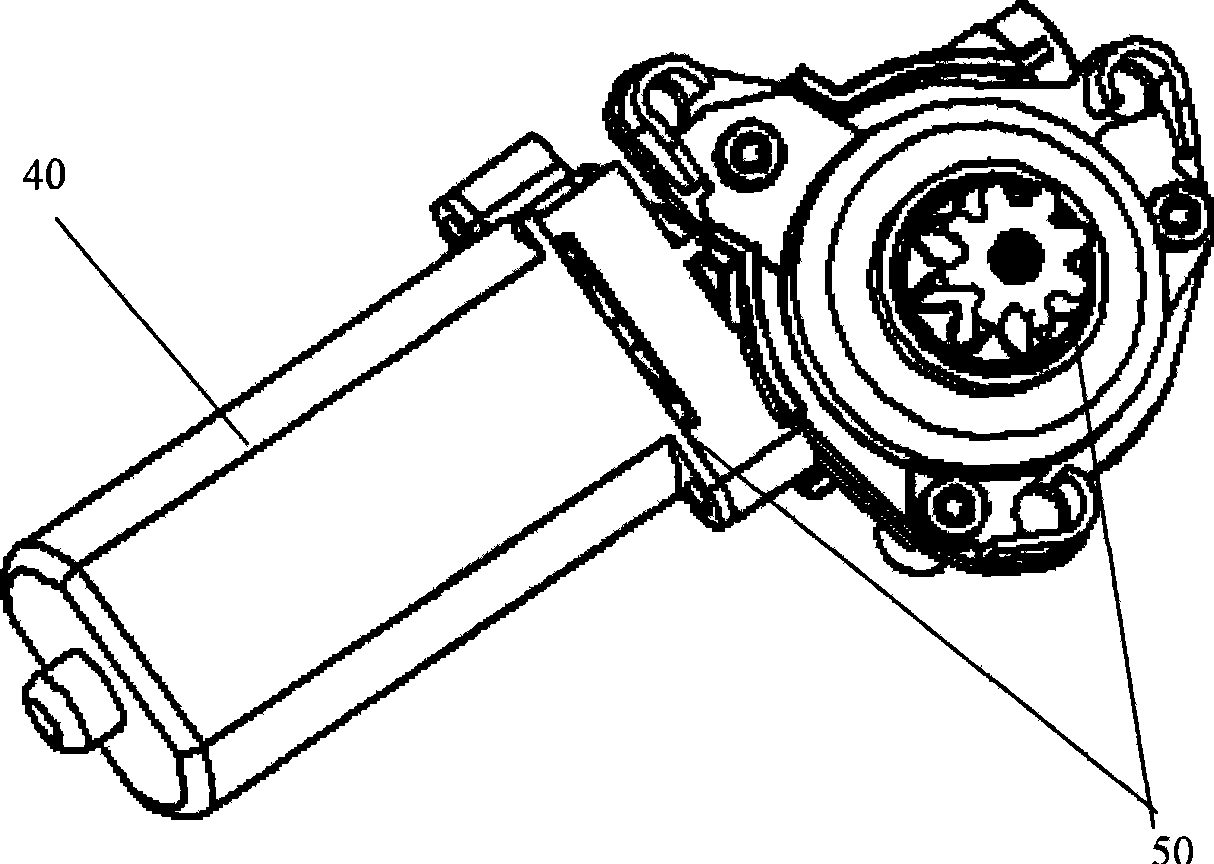

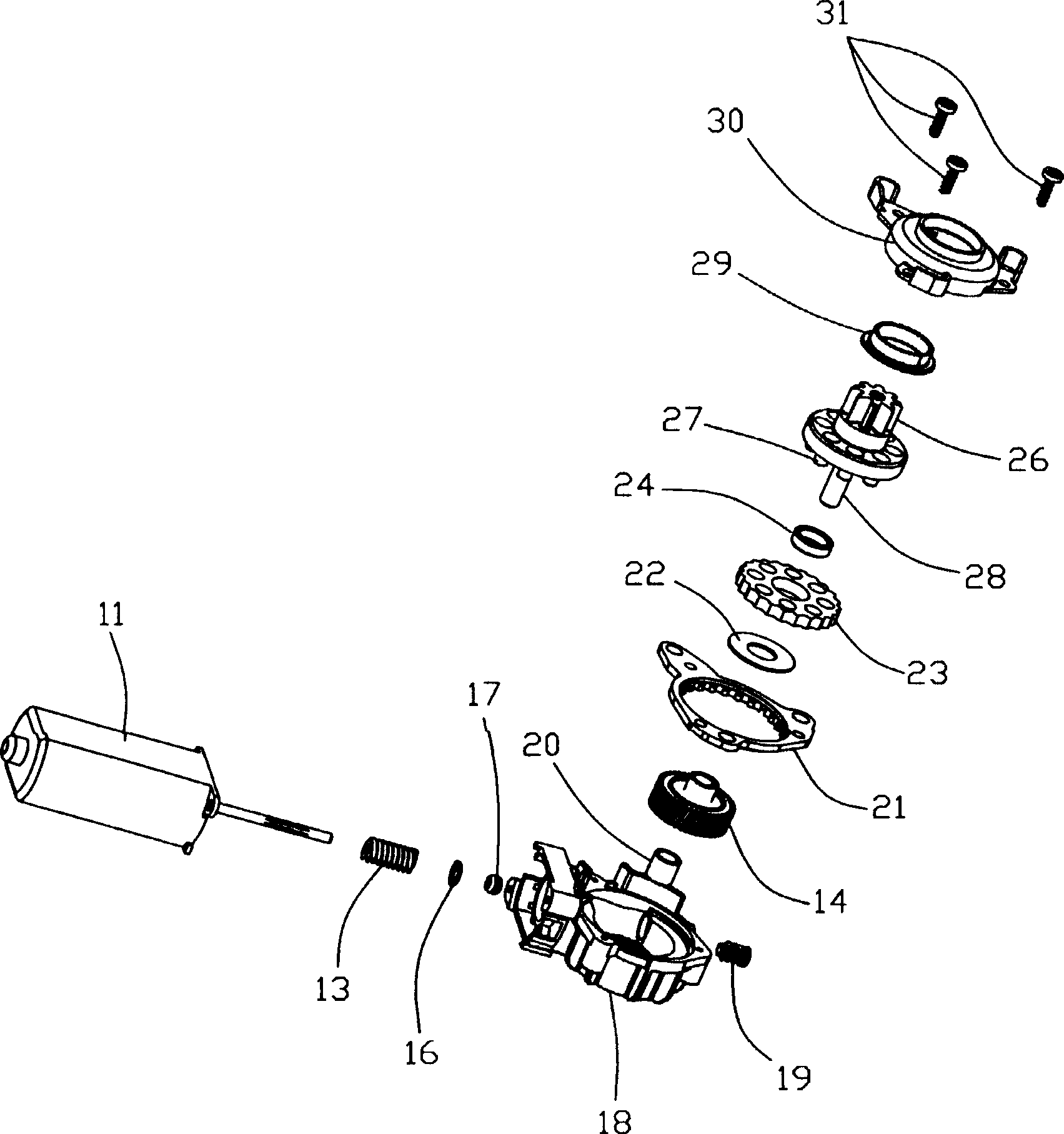

[0022] figure 2 It is an overall assembly diagram of a preferred embodiment of the gear motor for seat adjustment device of the present invention. As shown in the figure, the gear motor for seat adjustment device of the present invention can be divided into two parts: a motor assembly 40 and a gearbox assembly 50 . image 3 It is a schematic diagram of an exploded structure of a preferred embodiment of a gear motor for a seat adjustment device of the present invention, including a 12V DC motor 11, a worm 13, a worm wheel 14 (with an eccentric wheel embedded therein), a bearing positioning ring 16, a spherical oil-impregnated bearing 17, a gear Box 18, adjusting screw 19 (inserted into the motor shaft), sliding oil bearing 20, inner ring gear 21, washer 22, cycloidal gear 23, bearing 24, turret 25, output gear 26, pin 27, and output gear 26 are fixed Connected rotating shaft 28, output gear bearing 29, case cover 30, screw 31 (M4 size). The motor assembly 40 is composed of a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com