Numerically-controlled horizontal-gantry fixed-girder milling machine for cycloid gears

A technology of cycloidal gears and fixed beams, which is applied to milling machine equipment, belts/chains/gears, gear teeth, etc., can solve the problems of inability to hob cycloidal gears with a small number of teeth, low precision, and low machining accuracy, so as to maintain high Accuracy and stability, accurate indexing and positioning, and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

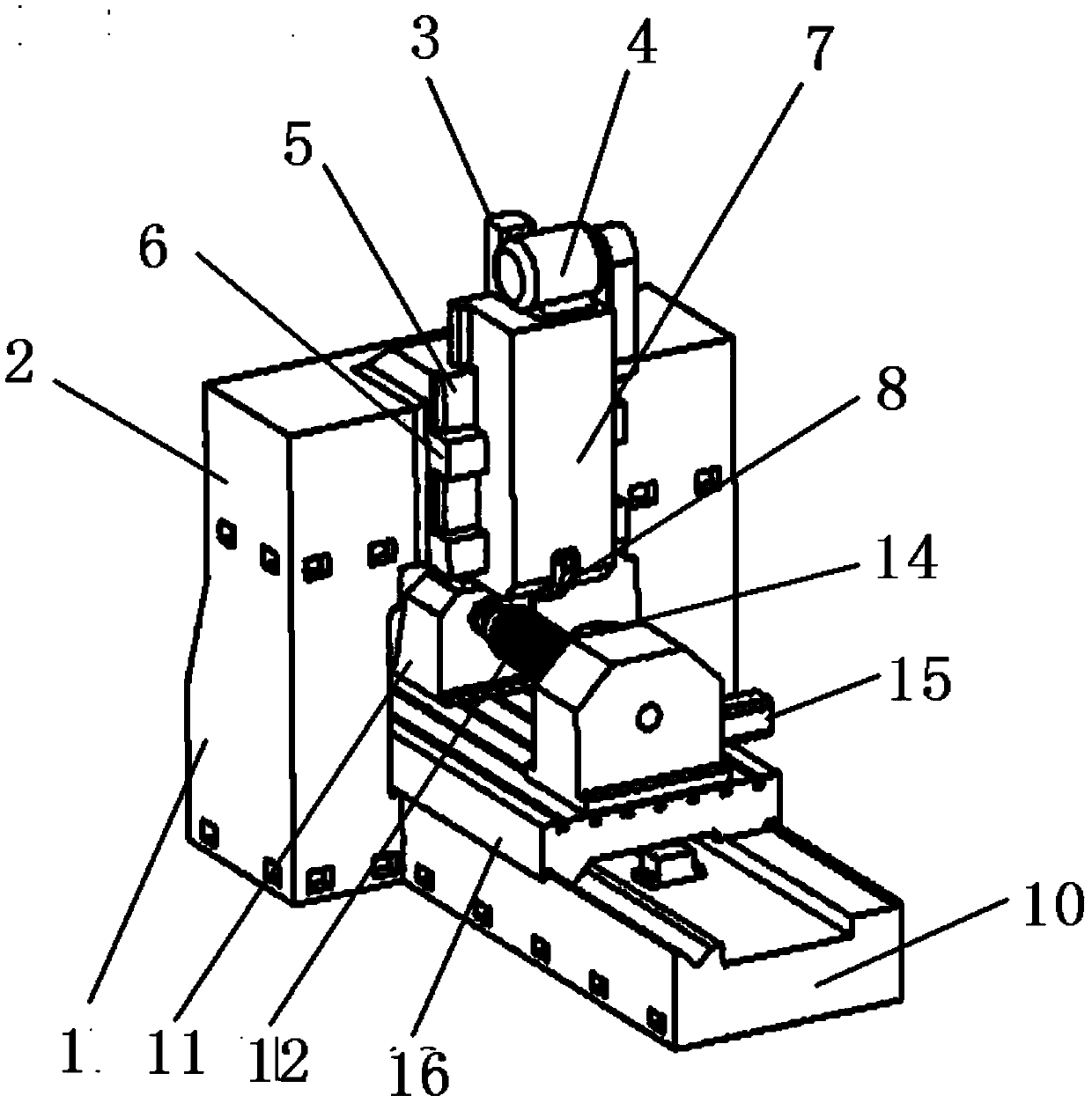

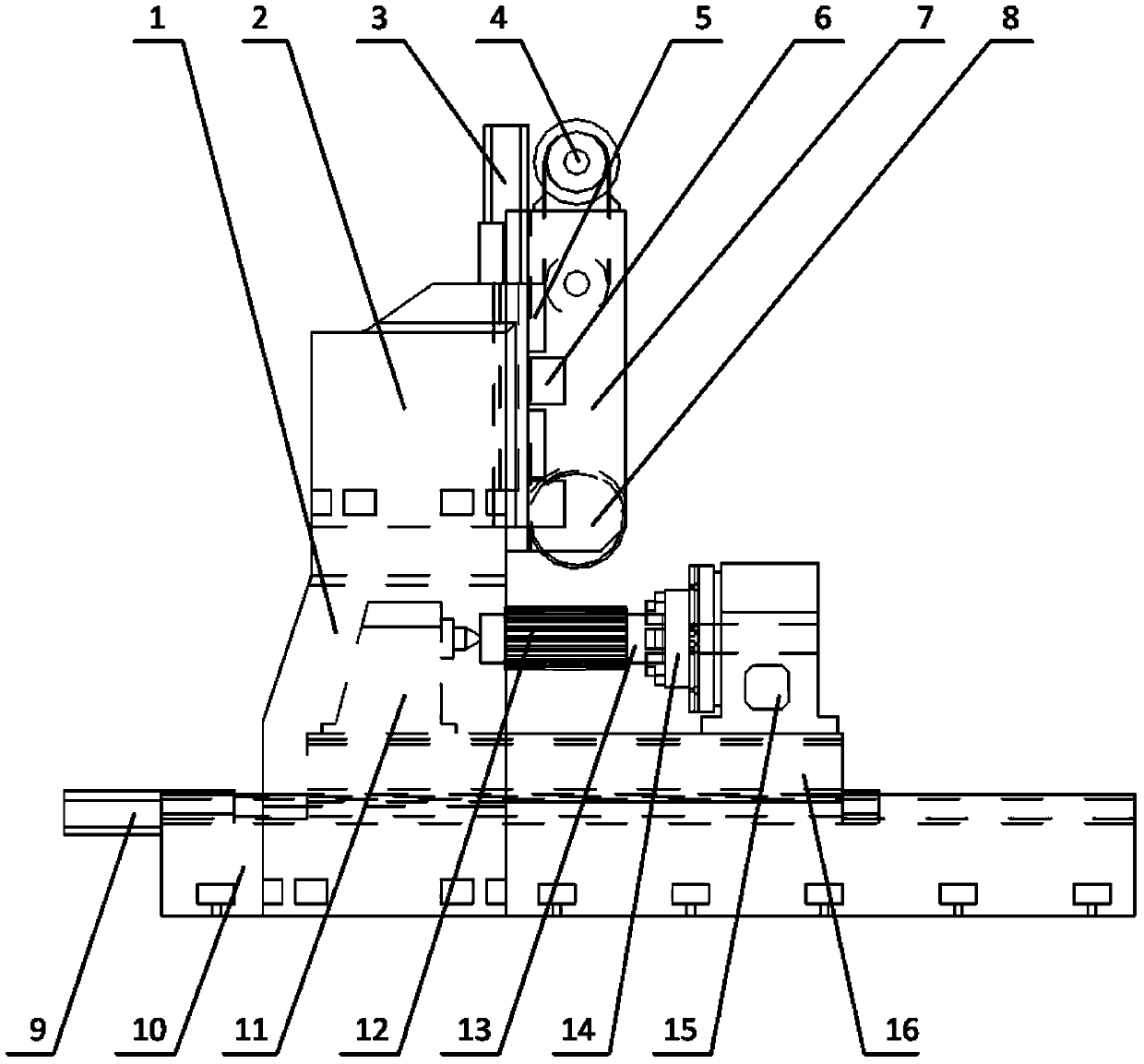

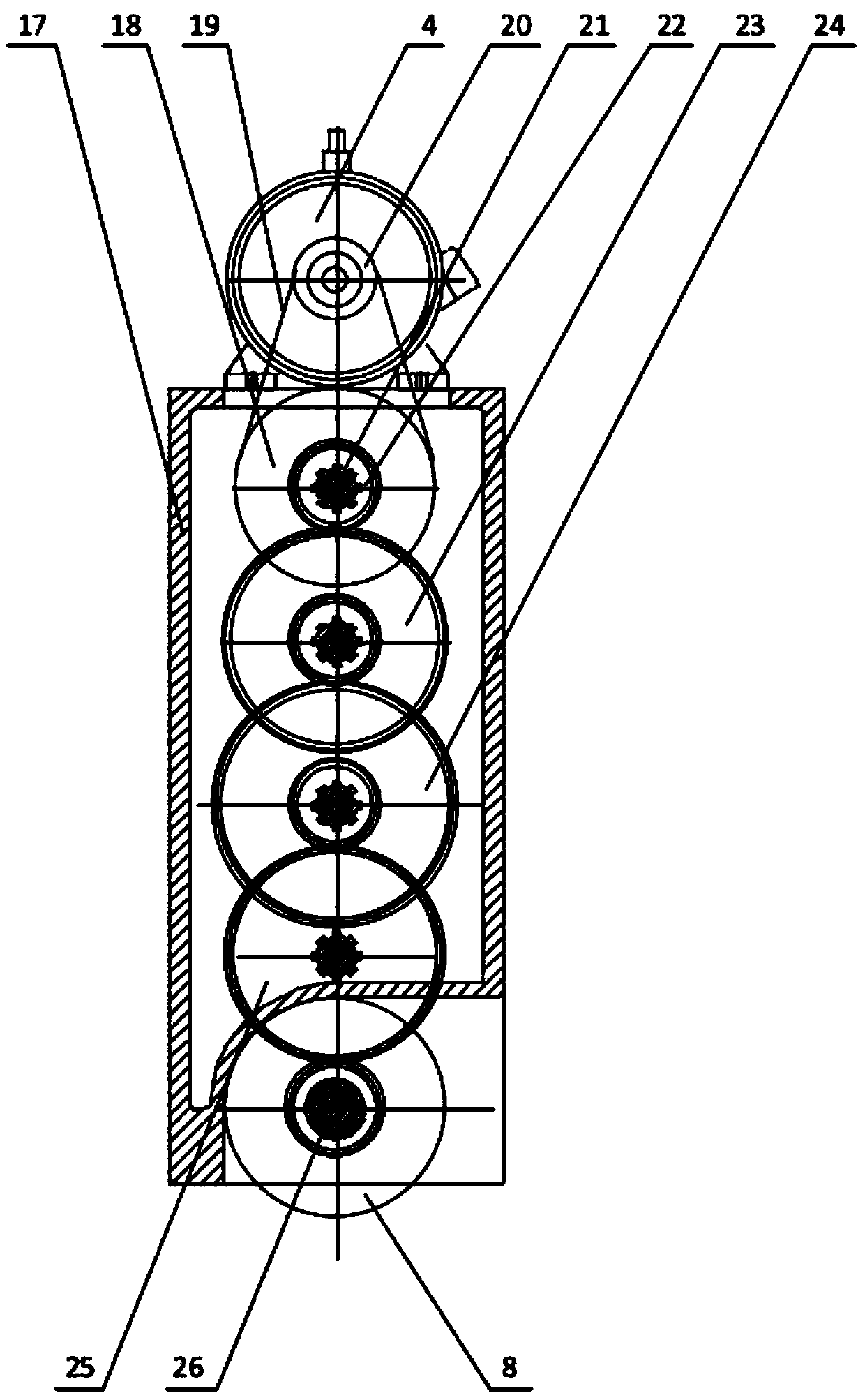

[0034] Such as figure 1 As shown, the CNC horizontal gantry fixed beam cycloidal gear milling machine of the present invention consists of a bed 10, a column 1, a rectangular workbench 16, a fixed beam 2, a milling spindle box 7, a disc milling cutter 8, and a vertical rotary indexing work Table 15, tail thimble support 11, cooling system, control system and other parts.

[0035] The bed 10 is installed on the foundation, and the upper side of the bed 10 is processed with a "one mountain and one moment" guide rail, which forms a composite sliding guide rail with the guide rail below the rectangular worktable 16, constraining all degrees of freedom except the axial movement of the workpiece. An X-axis axial feed system 9 is provided between the bed 10 and the rectangular worktable 16, and a linear feed servo system is formed by a servo motor, a planetary reducer, a bearing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com