Pin gear cycloid gear driving device and speed reducer thereof

A technology of gear reducer and cycloid gear, applied in the direction of gear transmission, transmission, belt/chain/gear, etc., can solve the problems of short life of the arm bearing, difficult to increase the size, and the transmission ratio cannot be less than 9, etc. To achieve the effect of improving position accuracy, improving stability and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

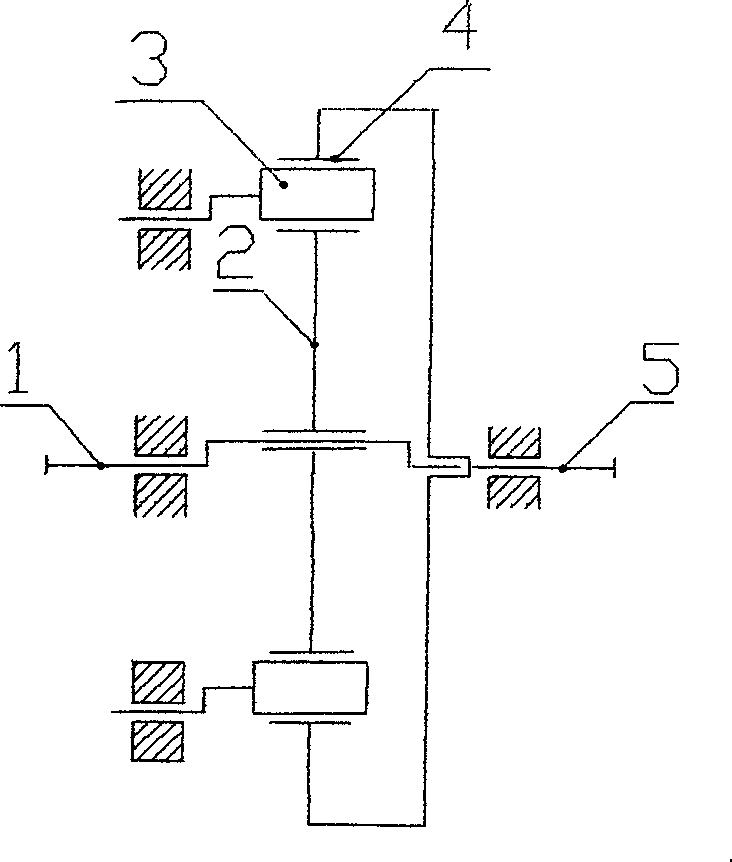

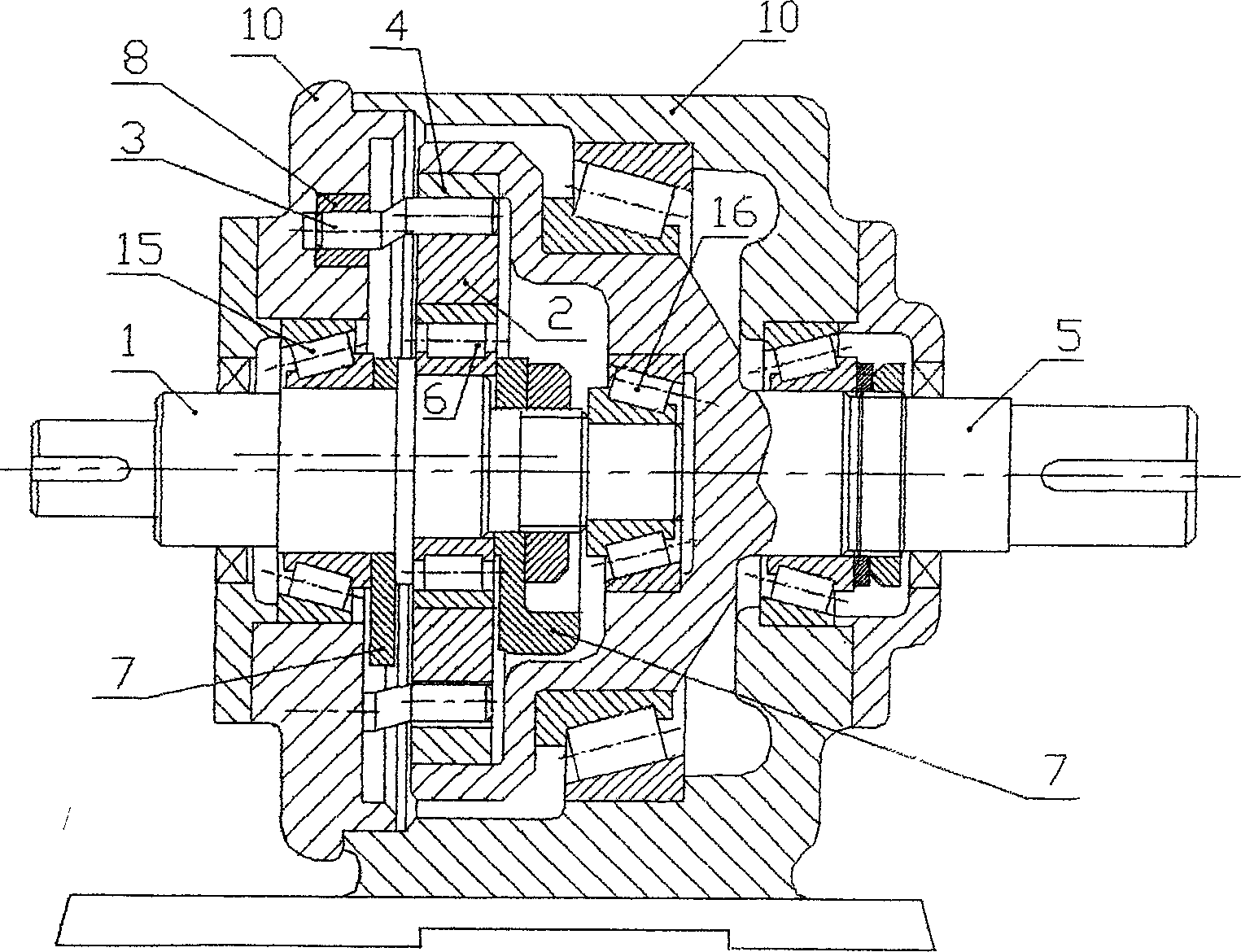

[0029] A needle-toothed cycloid gear reducer, its structure schematic diagram is as follows figure 2shown. The reducer is mainly composed of an input shaft (1), a rotating arm bearing (6), a balance weight (7), a circular wheel (2), pin teeth (3), a pin tooth bearing (8), and a hypocycloid wheel (4) 1. Output mechanism is composed of parts such as output shaft (5) and housing (10). The round wheel (2) is sleeved on the eccentric shaft of the input shaft (1) through the rotating arm bearing (6). The input shaft (1) is equipped with a balance weight (7) to balance the eccentric shaft. The pin teeth (3) pass through the pin teeth The bearing (8) is fixed on the casing (10), and the hypocycloidal wheel (4) is fixedly connected with the output shaft (5) into one body, and is supported on the casing (10) through the bearing. Input shaft (1) outer end is contained on the casing (10) by bearing I (15), and inner end is contained in output shaft (5) li by bearing II (16). When the ...

Embodiment 2

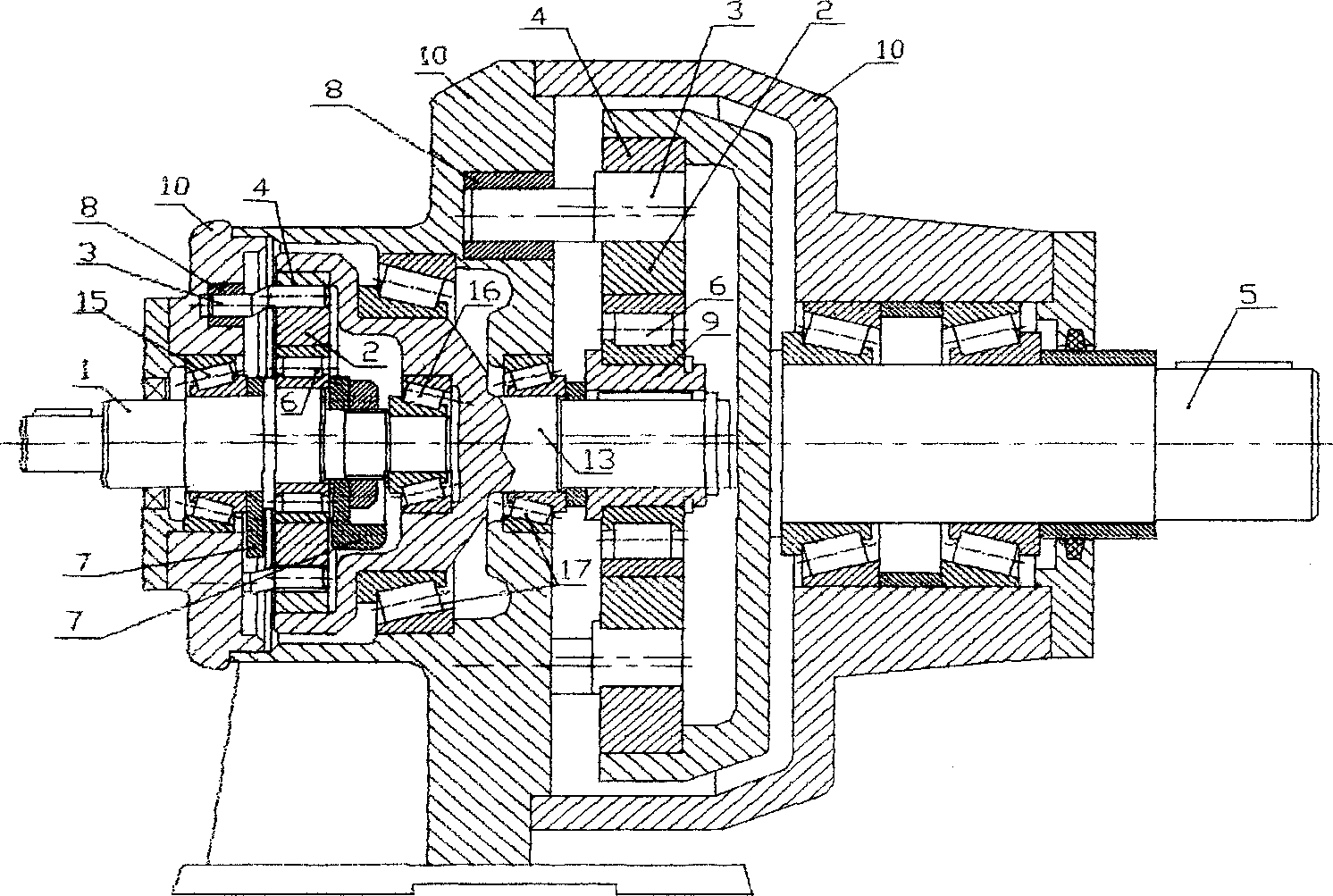

[0031] A two-stage pin-toothed cycloid gear reducer, its structure schematic diagram is as follows image 3 shown. The reducer is equipped with two series-connected pin-toothed cycloid translational gear transmission mechanisms. The epicycloid wheel (2) of the first-stage transmission mechanism is sleeved on the eccentric shaft of the input shaft (1) through the arm bearing (6). Above, the input shaft (1) is equipped with a balance block (7) to balance the eccentric shaft, the pin teeth (3) are fixed on the housing (10) through the pin gear bearings (8), and the hypocycloid wheel (4) and the middle The shaft (13) is fixedly connected, and the intermediate shaft (13) is supported on the housing (10) through bearings. The intermediate shaft (13) and its eccentric sleeve (9) constitute the input shaft of the second-stage transmission mechanism, and the second-stage swings outward The wire wheel (2) is set on the eccentric sleeve (9) of the intermediate shaft (13) through the rot...

Embodiment 3

[0033] A pin tooth cycloidal gear reducer with sprocket output, its structure diagram is as follows Figure 4 shown. The reducer is mainly composed of an input shaft (1), a bearing (14), a rotating arm bearing (6), a circular wheel (2), a pin tooth (3), a pin tooth bearing (8), a hypocycloid wheel (4), The output mechanism is composed of parts such as sprocket wheel (12), sprocket wheel bearing (11) and housing (10). The input shaft (1) is supported on the casing (10) through the bearing (14), the round wheel (2) is sleeved on the eccentric shaft of the input shaft (1) through the rotating arm bearing (6), and the pin teeth (3) pass through the pin The toothed bearing (8) is fixed on the casing (10), and the hypocycloidal wheel (4) is fixedly connected with the sprocket (12) into one body, and is supported on the casing (10) through the sprocket bearing (11). When the input shaft (1) rotates, the rotating arm bearing (6) drives the circular wheel (2) to move, and due to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com