Reducer with bevel gear and cycloid in large transmission ratio for ore grinding machine

A ratio reducer and bevel gear technology, which is applied in the field of mine mill bevel gear-cycloidal large transmission ratio reducer, can solve the problems of novelty and creativity of the invention concept

Inactive Publication Date: 2011-09-21

吴江科技创业园管理服务有限公司

View PDF5 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The planetary part of the invention is related to ①Cheng Daxian's "Mechanical Design Manual" Volume 3. Figure 14-5-31; ②Zhu Xiaolu's "Gear Transmission Design Manual" Figure 7-23; ③"Suspension Balanced Planetary Gear Reducer" 95243413.X; ④ Figure 8-4 of Zhang Zhan's "Planetary Differential Transmission Device";

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

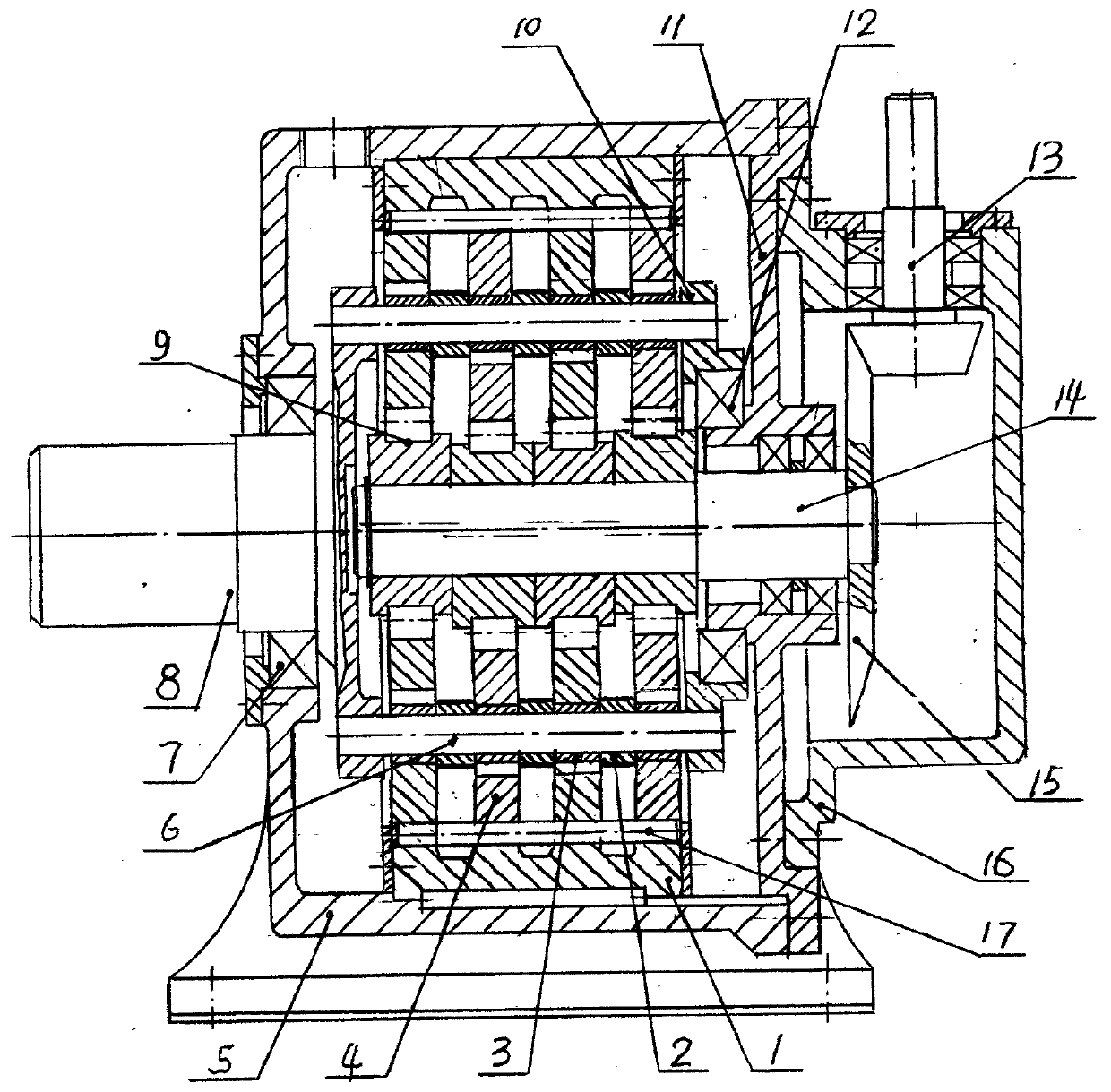

The invention relates to the technical field of reducing the speed of an ore grinding machine. A reducer with a bevel gear and a cycloid in a large transmission ratio for an ore grinding machine is characterized by comprising a bevel gear pair and a cycloid transmission part; the bevel gear pair comprises driving and driven bevel gears; in the cycloid transmission part, (A) needle pin semi-buried holes are uniformly distributed on a needle gear shell, and the needle pins without sleeves are movably matched with the semi-buried holes; (B) a W output mechanism is composed of an output shaft, a column pin, a uniform loading disc and an annular plate; two sides of the W output mechanism are supported on an inner hole of a machine body and the outer circle of a flange in an end cover through bearings; in four single-eccentric bearings, the phase difference between the first bearing and the second bearing and the phase difference between the third bearing and the fourth bearing are 180 DEG and the phase of the second bearing is same as that of the third bearing. In the invention, the reducer has the beneficial effects as follows: (1) the bearing capability is improved by 2-3 times; (2) the length of the axial direction is reduced by 45-55% and the cost is reduced by 40-50%; (3) the reversed installation service life of a cycloid gear is doubled; and (4) the inertia force and the inertia moment are completely balanced in theory when the reducer is operated.

Description

Mining mill bevel gear - cycloid large transmission ratio reducer technical field The invention relates to the technical field of mine mill deceleration, and relates to a bevel gear-cycloid large transmission ratio reducer for mine mills. Background technique CITIC Heavy Industry Machinery Co., Ltd., Luoyang Mining Machinery Design and Research Institute "Conical Planetary Large Transmission Ratio Reducer for Mining Mill Slow Drive Transmission" 200810231115.8 to meet the needs of mining mill slow drive work. The planetary part of the invention is related to ①Cheng Daxian's "Mechanical Design Manual" Volume 3. Figure 14-5-31; ②Zhu Xiaolu's "Gear Transmission Design Manual" Figure 7-23; ③"Suspension Balanced Planetary Gear Reducer" 95243413.X; ④ Figure 8-4 of Zhang Zhan's "Planetary Differential Transmission Device"; In addition, the invention claims that the transmission efficiency is ≥97%, but Zhu Xiaolu's "Gear Transmission Design Manual" 1030 pages, "Mechanical Transmi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): F16H1/28F16H57/02F16H57/08

CPCF16H1/32

Inventor 吴声震

Owner 吴江科技创业园管理服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com