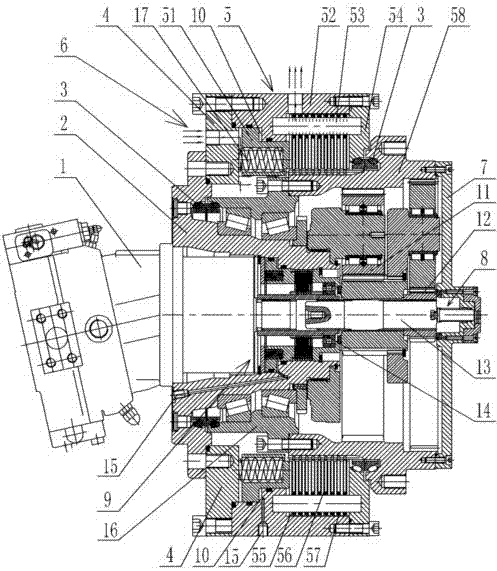

Novel double-braking rim driving device

A wheel-side drive, double-brake technology, applied in the direction of transmission parts, brake types, brake actuators, etc., can solve problems such as damage, torque increase, friction and high temperature deformation, etc., to avoid action failure and transmission torque increase. Large, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

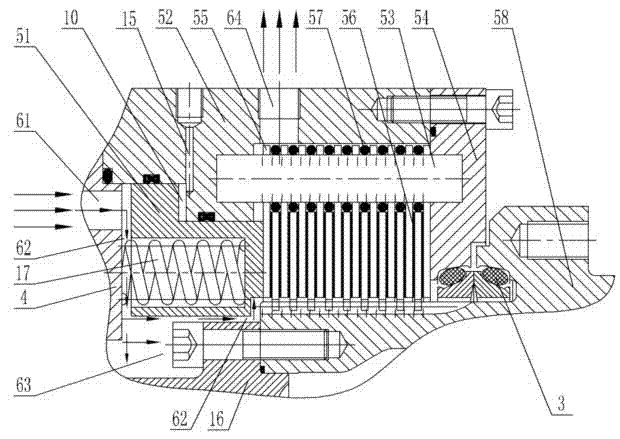

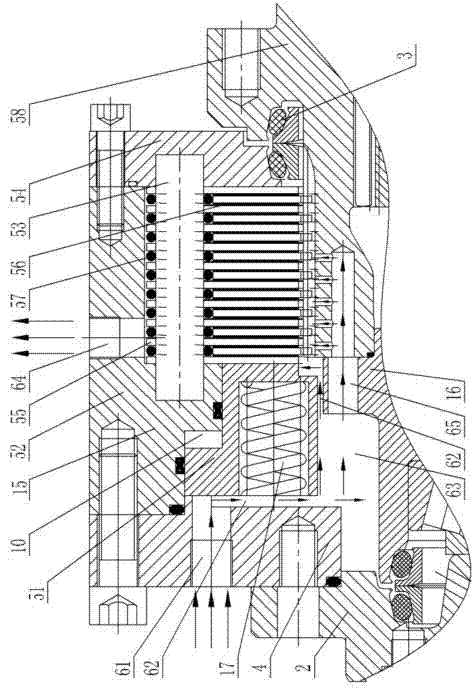

[0020] The embodiments of the present invention will be described in detail below according to the above-mentioned drawings.

[0021] like Figure 1~Figure 5 As shown, 1. Hydraulic motor, 2. Support seat, 3. Heavy-duty floating seal ring, 4. Support plate, 5. Service brake, 51. Piston, 52. Shell, 53. Connecting rod, 54. Mounting plate, 55 .Steel sheet, 56. Moving friction plate, 57. Rubber ring, 58. Internal gear housing, 6. Cooling circulation system, 61. Cold oil inlet, 62. Oil passage gap, 63. Oil chamber, 64. Hot oil outlet, 65. Oil hole, 7. Cover plate, 8. Manual release device, 81. Release shaft, 82. Return spring, 83. Cover, 9. Parking brake, 91. Collar, 92. Fixed plate, 93. Piston sleeve, 94. Wet brake pad set, 95. Fixed sleeve, 96. Bearing, 10. Oil chamber, 11. Secondary planetary reduction mechanism, 12. Primary center wheel, 13. Connecting shaft, 14. Spline Connection sleeve, 15. oil delivery channel, 16. support sleeve, 17. push spring.

[0022] New wheel drive ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com