Stroke differential type high-energy hydraulic drive down-hole hammer

A down-the-hole impactor and differential technology, which is applied to the driving device for drilling in the borehole, drilling equipment, earthwork drilling and production, etc., can solve the problems of unfavorable high-energy continuous output, long overall axial dimension, and high processing accuracy requirements , to achieve the effects of improving drilling efficiency in hard rock, long service life, and high final impact velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

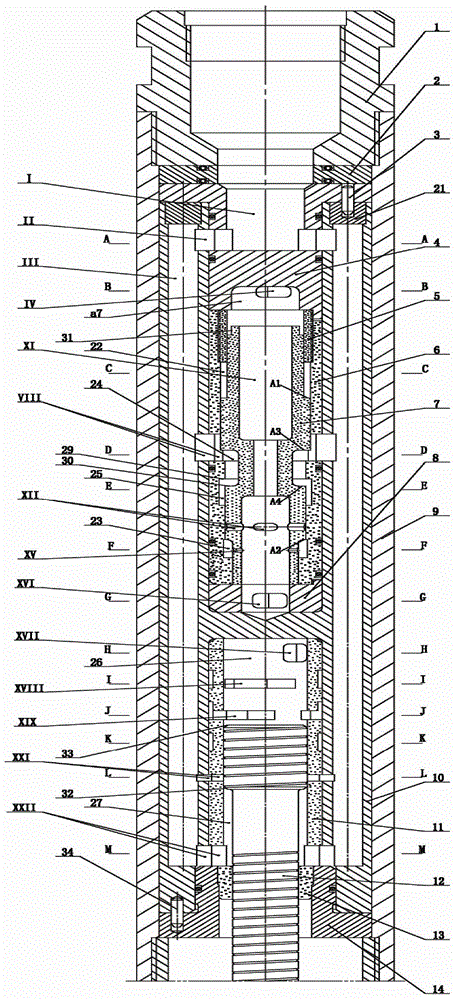

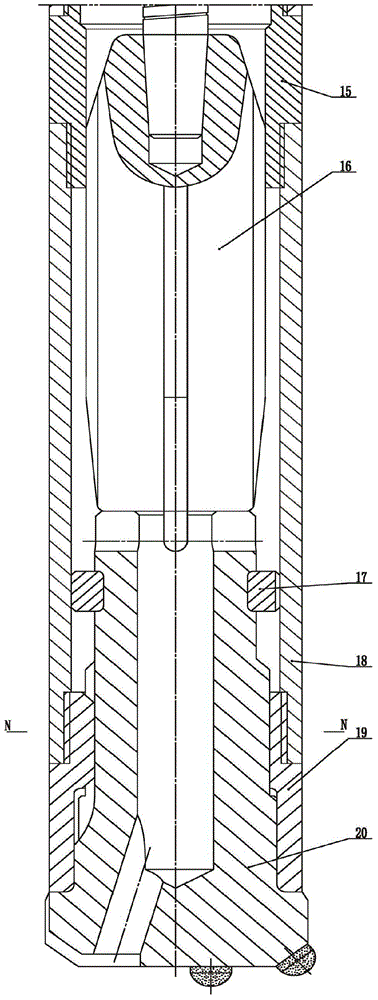

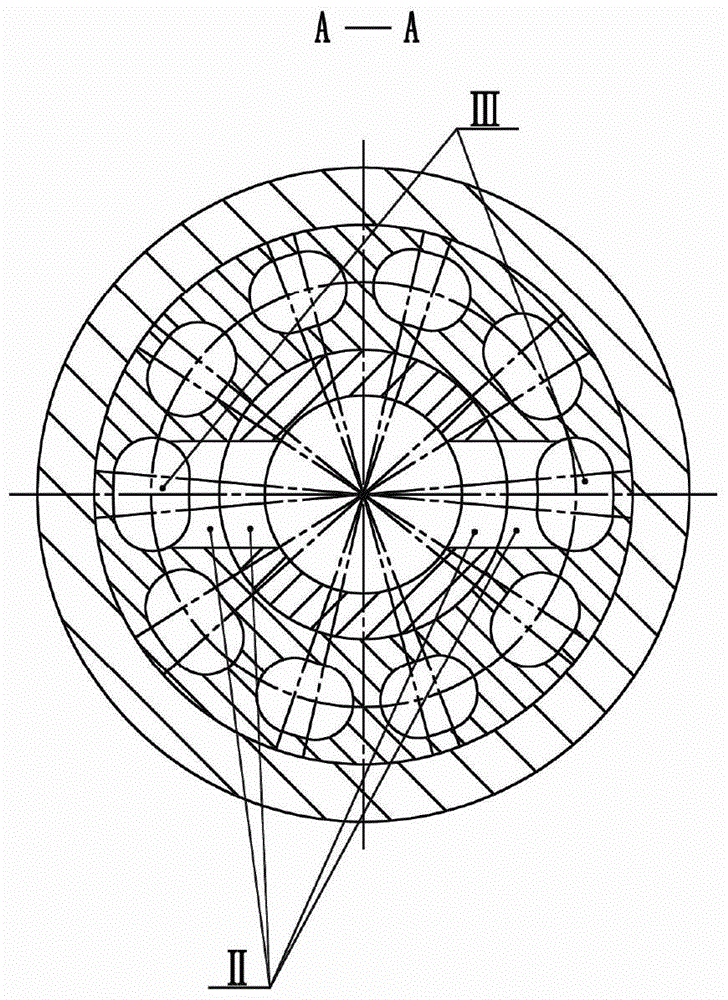

[0031]The stroke differential high-energy hydraulic down-the-hole impactor is a sliding fit between the spline on the drill bit 20 and the spline groove on the spline sleeve 19, the drill bit 20 slides in the axial direction, and aligns with the lower step of the drill bit 20 through the semicircular clamp 17. The drill bit 20 is limited to prevent the drill bit from slipping from the spline sleeve. The spline sleeve 19 is connected to the outer pipe 18 through threads, the outer pipe 18 is threaded to the middle joint 15, the middle joint 15 is connected to the outer cylinder 9 through threads, and the cylinder liner 11 The end cover sleeve 13 is fitted into the cylinder body 10 and the lower cylinder head 14 respectively by interference fit. The piston 12 is processed into two sections with different diameters to form a piston step surface 32. The entir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com