Impact drill

A technology of impact drill and casing, applied in the directions of portable impact tools, striking tools, portable drilling rigs, etc., can solve the problem of large axial size of impact drills

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

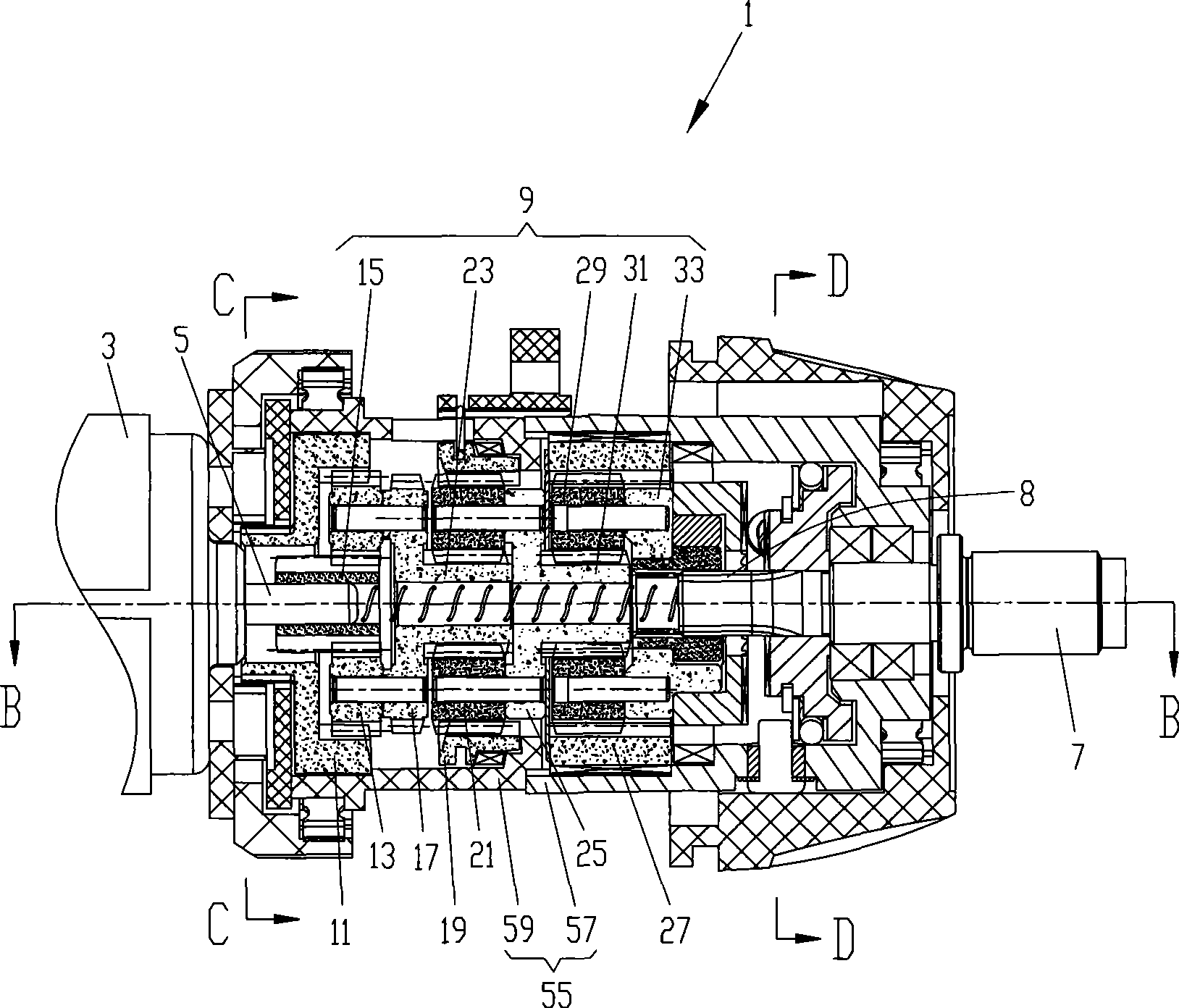

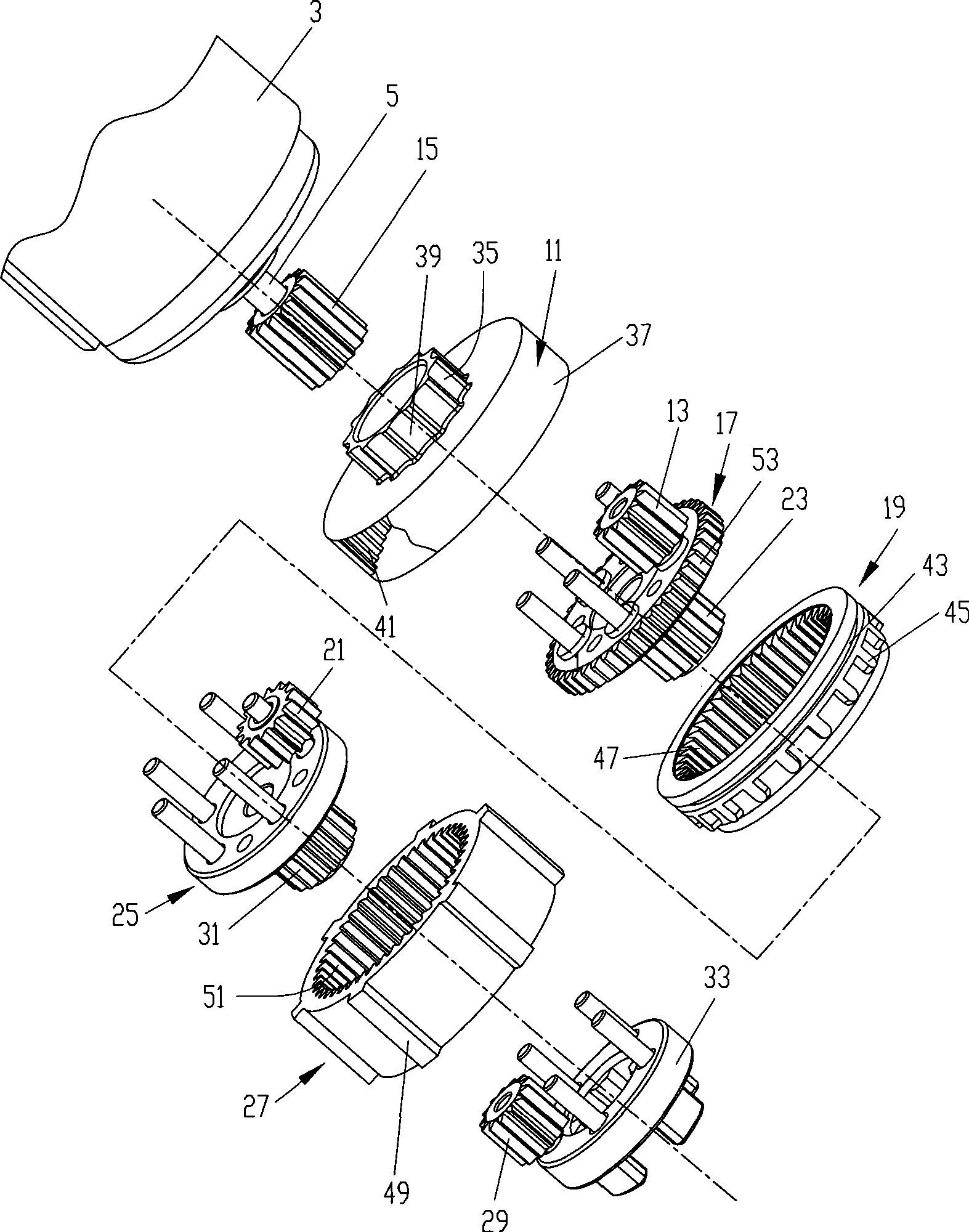

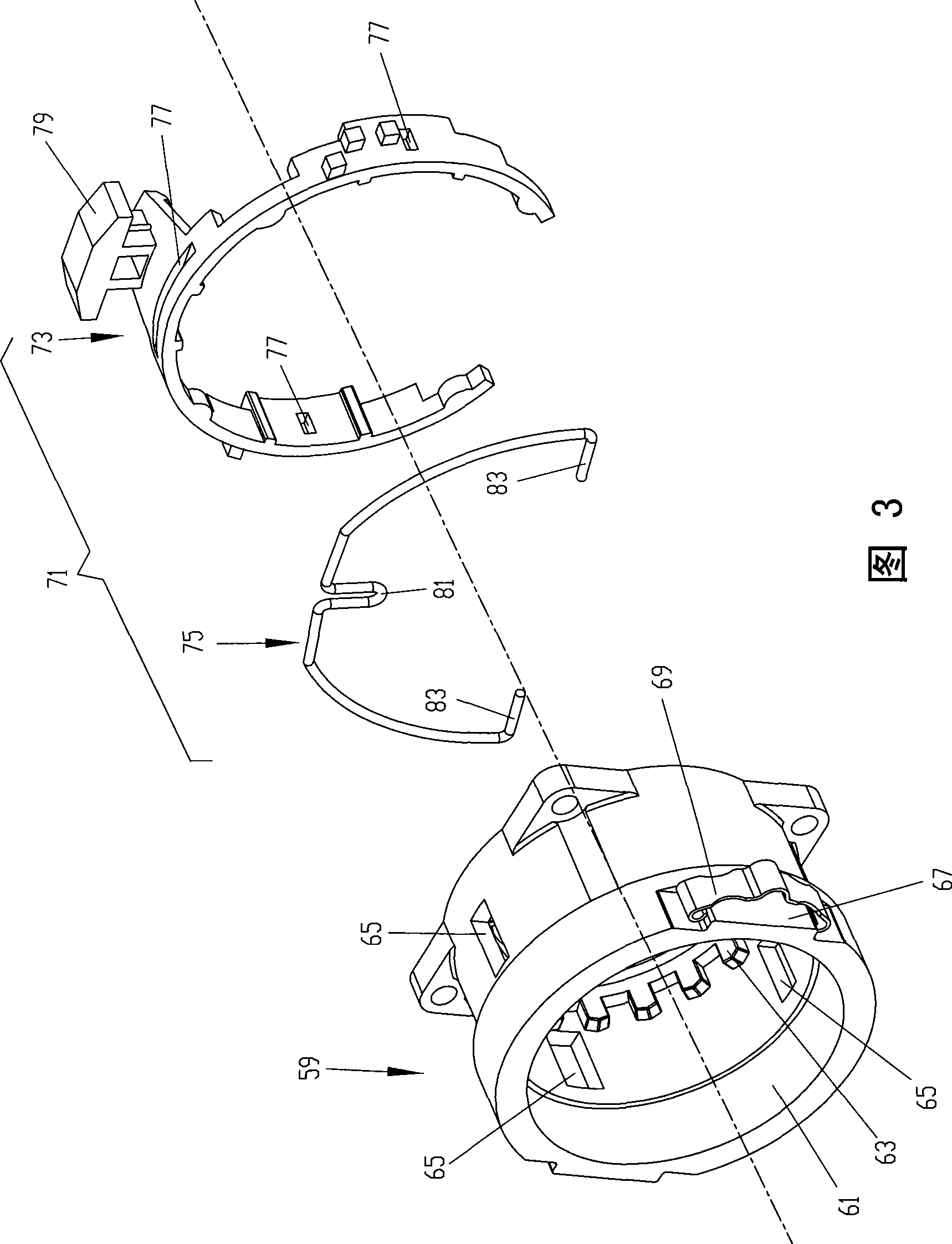

[0024] refer to Figure 1 to Figure 2 , a three-function impact drill 1, can be operated in one of three modes of screwdriver, drilling and impact. The three-function hammer drill 1 includes a motor 3 having a rotating motor output shaft 5 for transmitting the rotational motion of the motor 3 to a spindle 7 . The main shaft 7 is located at the front end of the hammer drill 1 for driving the working head (not shown), and the rear end of the main shaft 7 is provided with an external spline 8 . A gear reduction mechanism 9 is provided between the motor 3 and the main shaft 7 , and the reduction gear mechanism 9 is used to reduce the higher rotational speed of the output shaft 5 of the motor and then transmit it to the main shaft 7 .

[0025] The gear reduction mechanism 9 includes a three-stage planetary gear set, the first-stage planetary gear set includes a first ring gear 11, the first planetary gear 13 meshes with the first ring gear 11, and the first sun gear 15 meshes with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com