Permanent magnet non-iron-core motor used for electric vehicle

An electric vehicle, ironless technology, applied in electric vehicles, motors, electric components, etc., can solve the problems of large vibration noise, large volume, large loss, etc., and achieve the effect of improving torque, small size, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

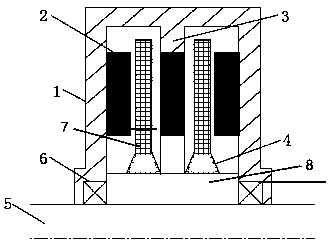

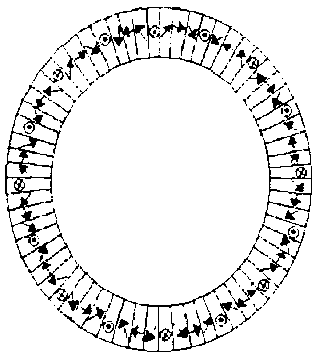

[0017] Below in conjunction with accompanying drawing, the present invention will be further described, as figure 1 The shown permanent magnet coreless motor for electric vehicles is characterized in that: two outer rotor discs (1), one motor middle rotor disc (3), two stator armatures (7), two stator armatures Pivot plate (4), permanent magnet (2) and bearing (6), shaft (5) and motor housing (8), the motor rotor consists of two outer rotor discs (1) and one middle rotor disc (3).

[0018] The motor casing (8) and the three rotor disks are all made of aluminum alloy, and the permanent magnet (2) is fixed on the rotor aluminum disk by bonding and steel wire welding. Since the motor rotor It is also a part of the motor casing (8), which is used as the hub of the automobile motor, thus avoiding the eddy current loss caused by the mutual movement of the permanent magnet (2) and the motor casing (8), and the shaft (5) is fixed on the motor through the bearing (6) On the rotor, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com