Magnetic flow switching type axial magnetic field magnetoelectric machine with middle stator structure

A magnetic flux switching, permanent magnet motor technology, applied in the shape/pattern/structure of the magnetic circuit, the shape/pattern/structure of the winding conductor, electrical components, etc., can solve the problem of unsuitable motors, and achieve high utilization and heat dissipation. The effect of good performance and short axial dimension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

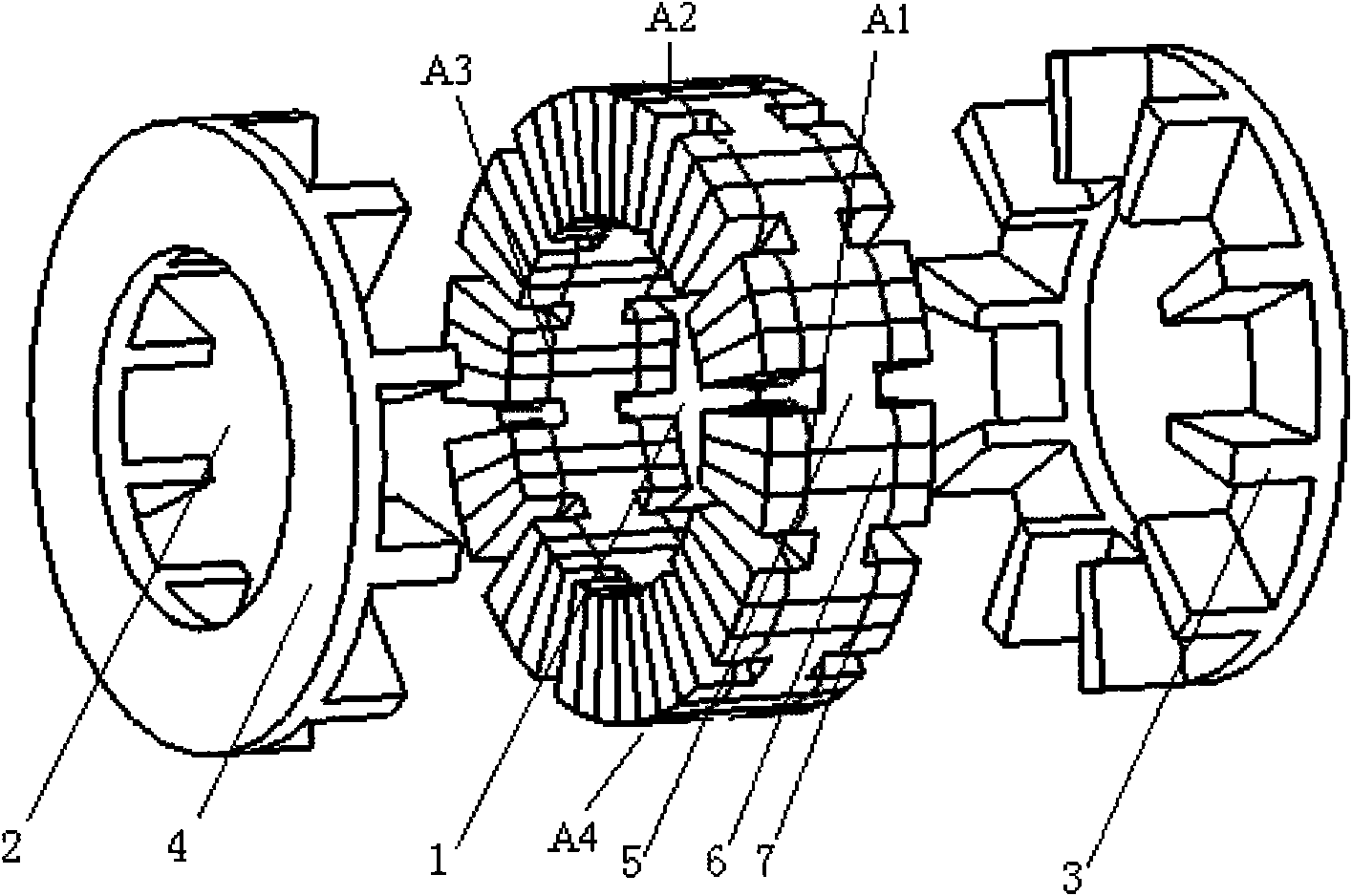

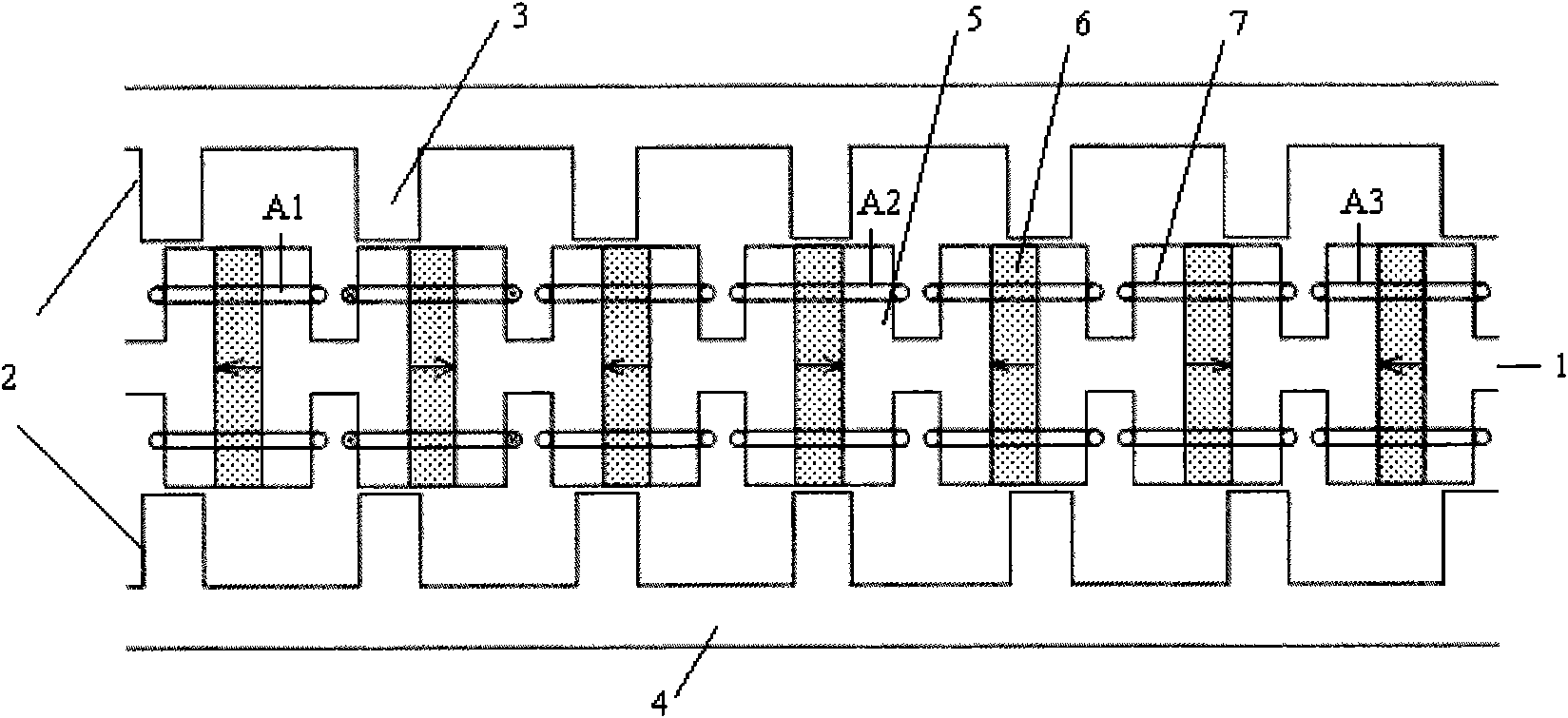

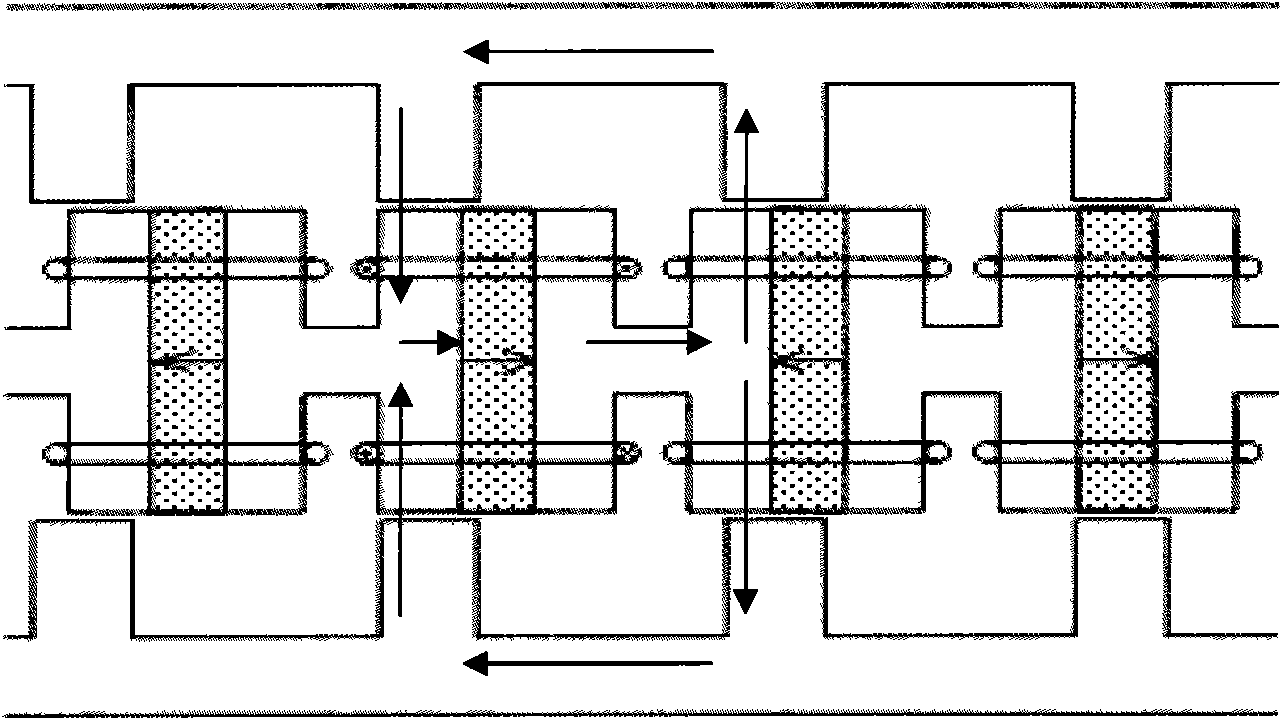

[0024] The intermediate stator structure magnetic flux switching axial field permanent magnet motor proposed by the present invention is a double air gap permanent magnet motor composed of a stator and two rotors. The stator and the rotor are installed coaxially, and the stator is clamped between the two rotors. There is an air gap between the rotor and stator. The structure of the two rotors is exactly the same, and they are symmetrical about the stator. The stator consists of 6a H-shaped magnetic cores, 6a permanent magnets and 6a concentrated windings composed of coils. H-shaped stator cores and permanent magnets are placed alternately to form a disk, and the two adjacent permanent magnets in the stator are magnetized in opposite directions. The 2a coils on each side of the stator are divided into three phases, and the four coils whose radial centerlines are perpendicular to each other (such as figure 1 The four coils A1, A2, A3 and A4 in the stator) are connected in seri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com