Hydraulic variable-speed micro-miniature turbofan engine with multi-rotor structure

A hydraulic variable speed, turbofan technology, applied in the direction of machines/engines, gas turbine devices, mechanical equipment, etc., can solve the problems of high cost, high difficulty in processing and assembly, and high difficulty in modeling, so as to save costs and reduce manufacturing Difficulty, the effect of simplifying the rotor structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

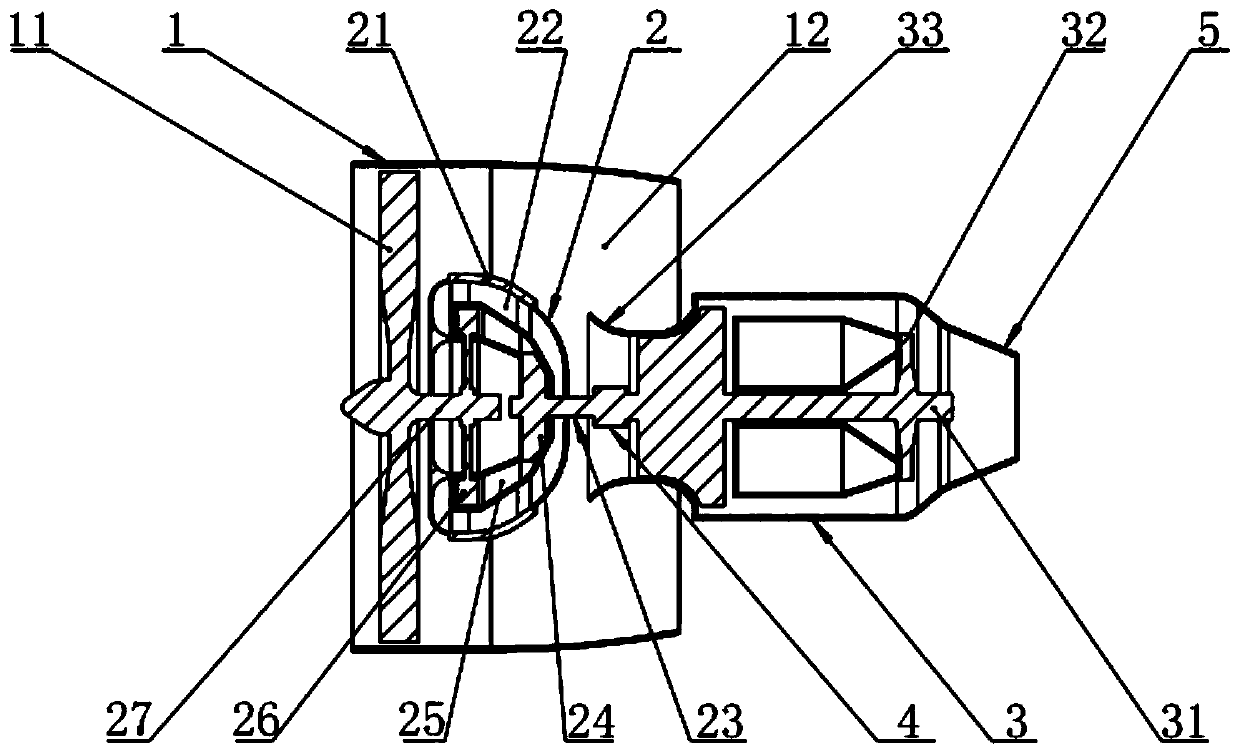

[0029] like figure 1 As shown, a micro turbofan engine with hydraulically variable speed and multi-rotor structure includes a core engine 3 and a fan casing 1. The core engine 3 includes a core machine main shaft 31, and the front end of the core engine 3 is provided with a fan 11 and a speed reducer. The reducer includes a reducer input shaft 23, a reducer housing 2, a reducer output shaft 27, a power turbine 26 and a driving impeller 24. One end of the reducer output shaft 27 is connected to the fan 11, and the other end of the reducer output shaft 27 is connected to the power turbine 26. One end of the input shaft 23 of the reducer is connected with the driving impeller 24, the other end of the input shaft 23 of the reducer is connected with the coupling 4, the other end of the coupling 4 is connected with the main shaft 31 of the core machine, the fan case 1, the reducer The casing 2 and the core engine 3 together form an outer duct 12 . Wherein, the front end of the core...

Embodiment 2

[0032] like figure 1 As shown, the reducer housing 2 is provided with an independently rotating reducer output shaft 27 and an independently rotating reducer input shaft 23 , and there is no rigid connection between the reducer input shaft 23 and the reducer output shaft 27 . Compared with the reduction gearbox structure of large engines and the belt reducer structure of some micro engines, the rotor structure of the turbofan engine is greatly simplified, and the problem of wear and tear of the reduction gears is avoided, so that the hydraulic variable speed multi-rotor structure micro turbofan The engine reducer requires no lubrication and requires no maintenance for transmission parts, resulting in longer life.

Embodiment 3

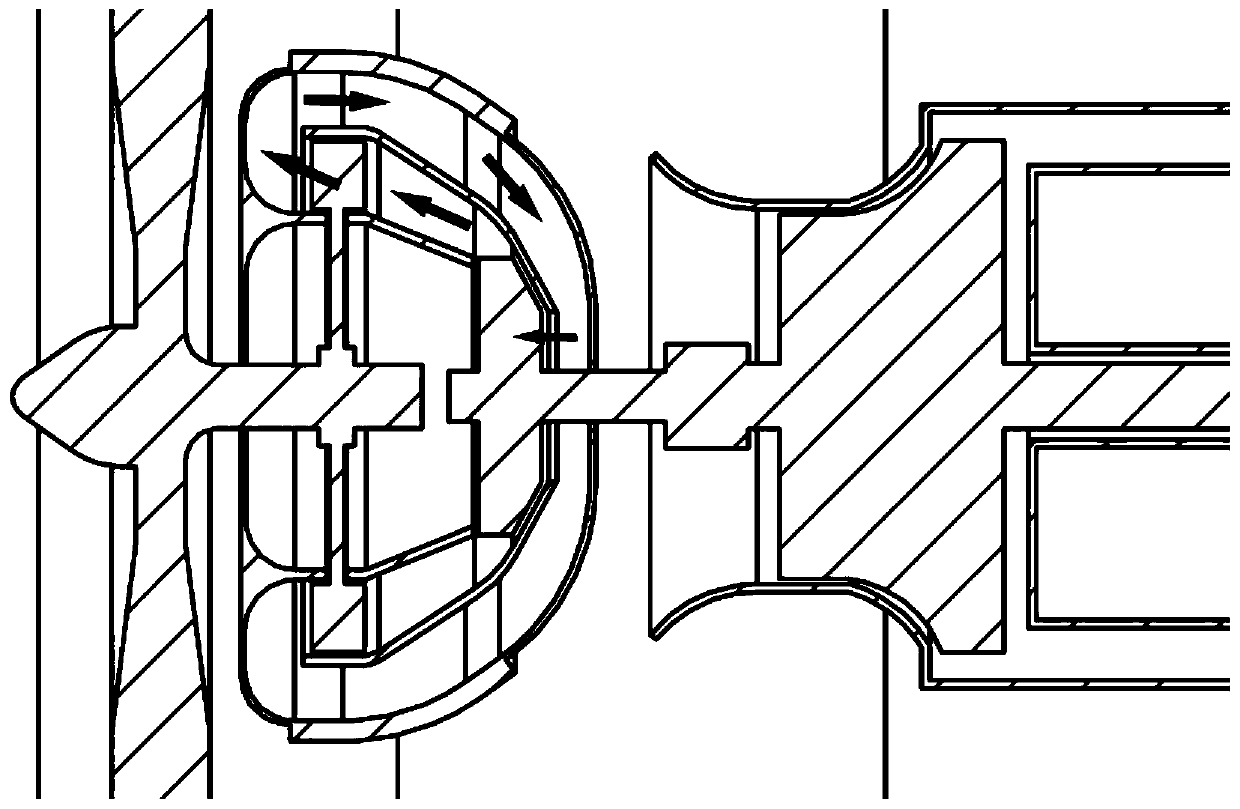

[0034] like figure 2 As shown, the reducer housing 2 is respectively provided with a reducer outer flow channel 22 and a reducer inner flow channel 25 , and the reducer outer flow channel 22 communicates with the reducer inner flow channel 25 . Wherein, the reducer cooling fin 21 is arranged on the reducer casing 2 close to the reducer outer flow channel 22 . The reducer casing 2 is filled with liquid.

[0035] As a preferred embodiment, the outer diameter of the driving impeller 24 is smaller than the outer diameter of the power turbine 26, using hydraulic flow to transfer energy, and balance the speed difference between the fan 11 and the core machine, so as to achieve the purpose of working at the optimum speed respectively , thereby improving the cruising range and economy of the aircraft.

[0036] like figure 1 and 2As shown, those skilled in the art can implement the present invention as a micro-miniature turbofan engine with hydraulically variable speed and multi-r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com