Fully sealed integrated RV speed reducer

A reducer, integrated technology, applied in mechanical equipment, transmission parts, gear transmission and other directions, can solve the problems of high precision requirements, long cycle, inconvenient for users to use, to achieve good working performance and reasonable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

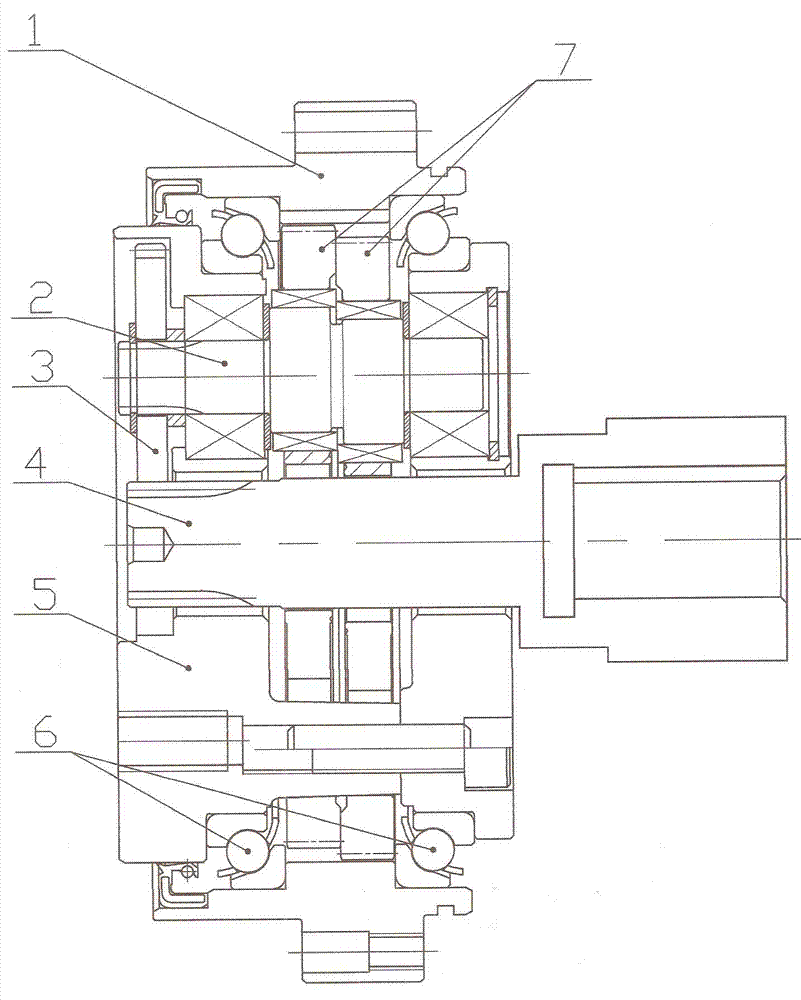

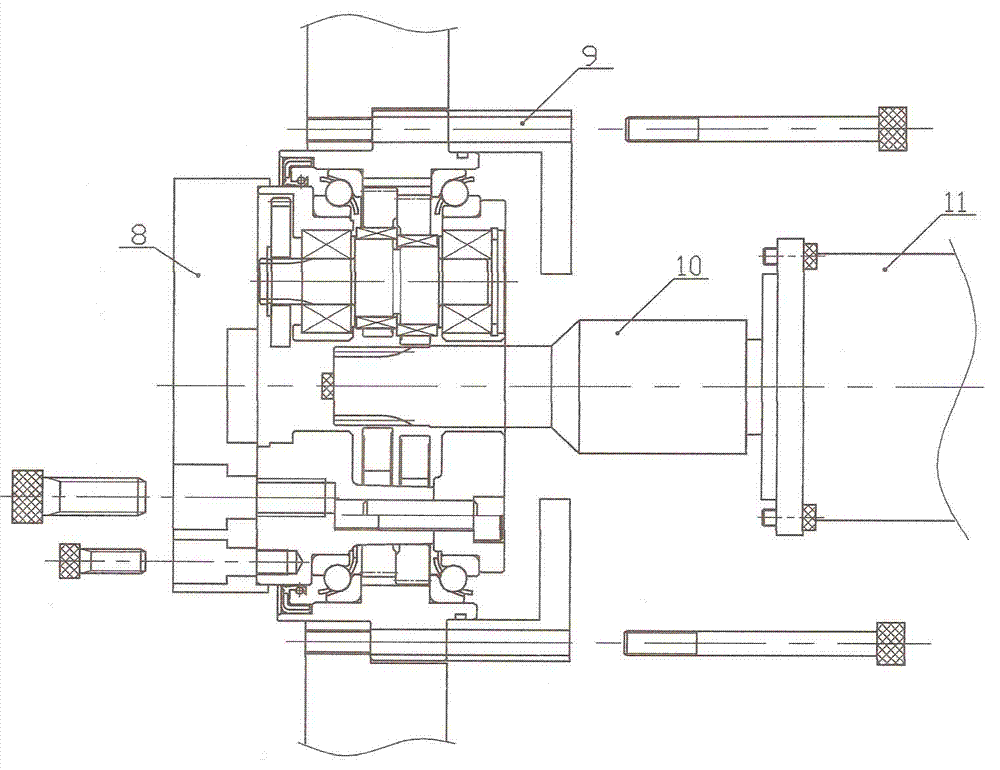

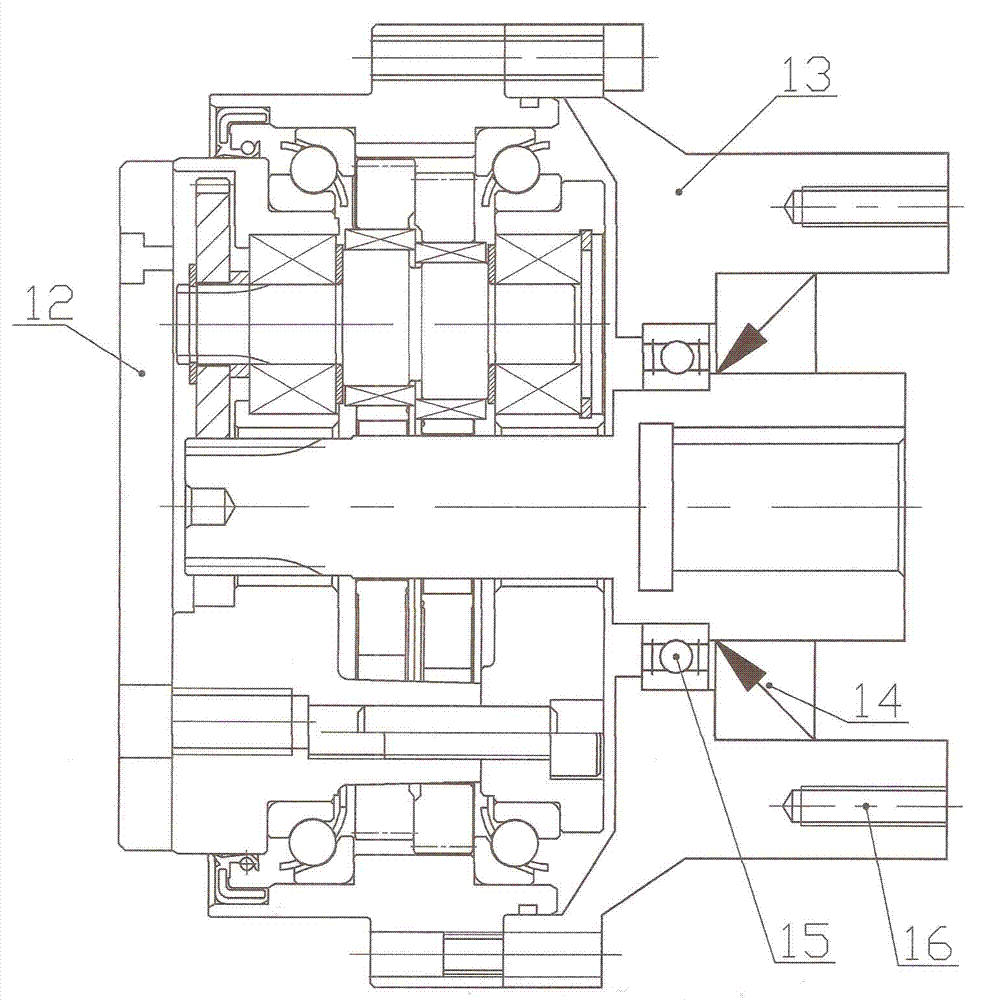

[0017] A fully-sealed integrated RV reducer comprises a second-stage cycloidal pinwheel deceleration structure composed of a pin gear housing, a cycloidal wheel and a needle roller, and a first-stage planetary deceleration mechanism composed of an input shaft and a planetary gear, The output disk rack is provided with an output end cover on the outside of the output disk rack, and the output end cover is fixed on the output disk rack of the RV reducer by screws, and a plurality of output threaded holes corresponding to the output threaded holes on the output disk rack are processed on the output end cover. Through hole, the pin gear shell is connected with the input end flange, the input shaft support bearing is arranged between the input end flange and the input shaft, and the skeleton oil seal is arranged between the input end flange and the input shaft; the input end flange is provided with multiple Threaded holes for servo motor mounting.

[0018] The present invention add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com