Double-disc cycloid cam planet driving device

A planetary transmission, cycloidal wheel technology, applied in the direction of gear transmission, transmission, belt/chain/gear, etc., can solve the problems of reduced transmission efficiency, poor dynamic balance characteristics, large meshing pair sliding, etc., to achieve high transmission accuracy and comprehensive efficiency, reducing the difficulty and cost of processing and manufacturing, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

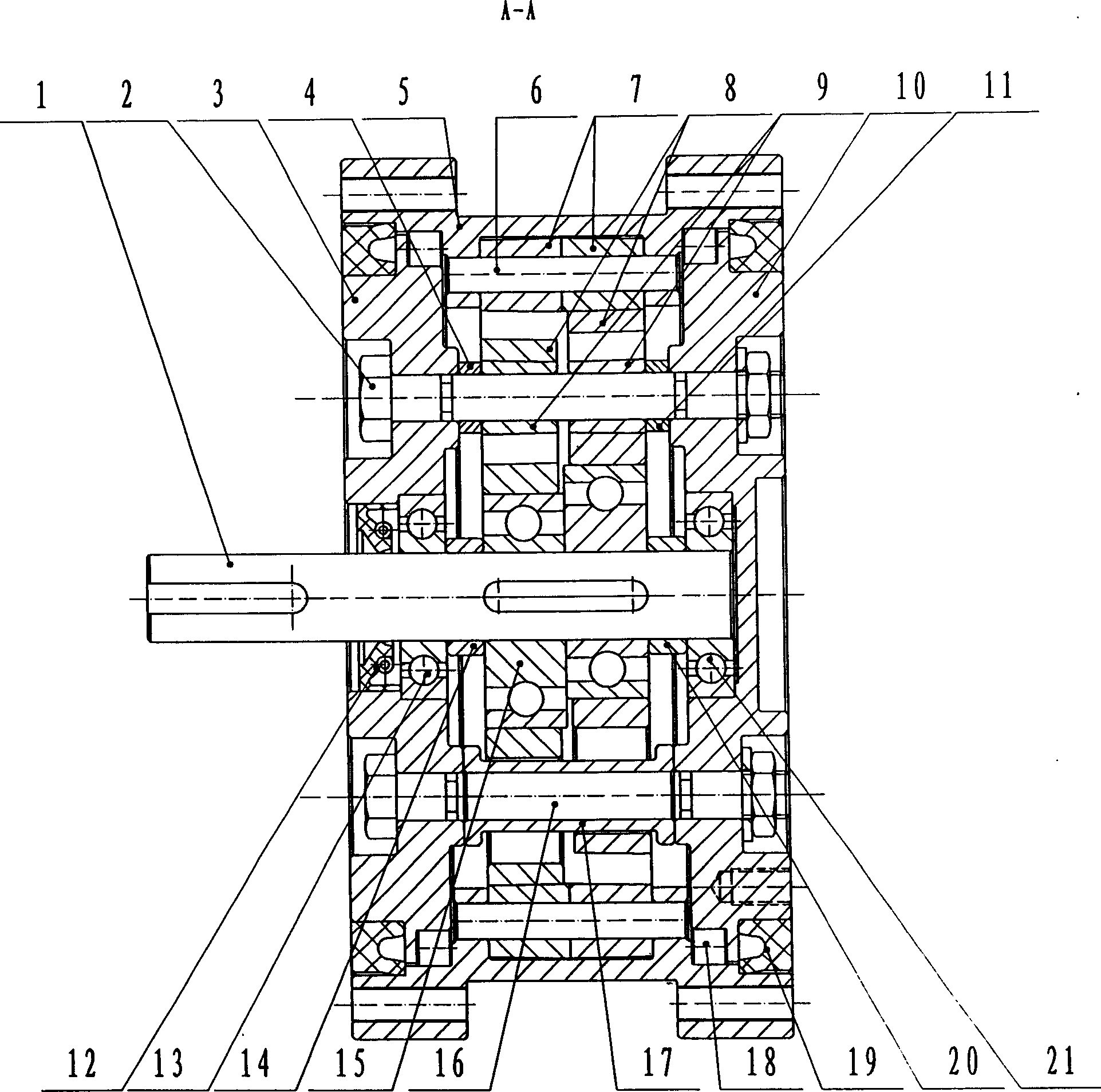

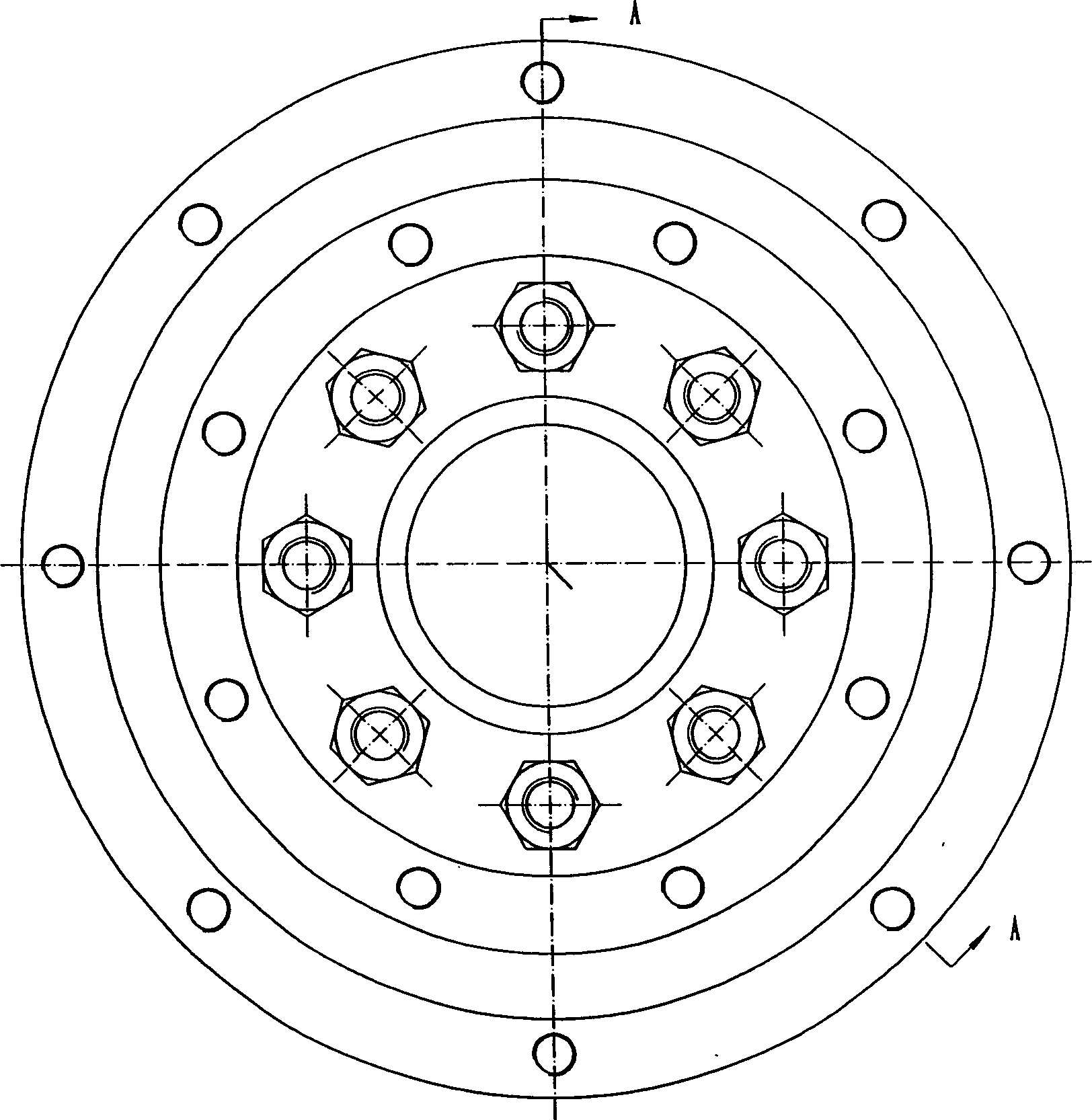

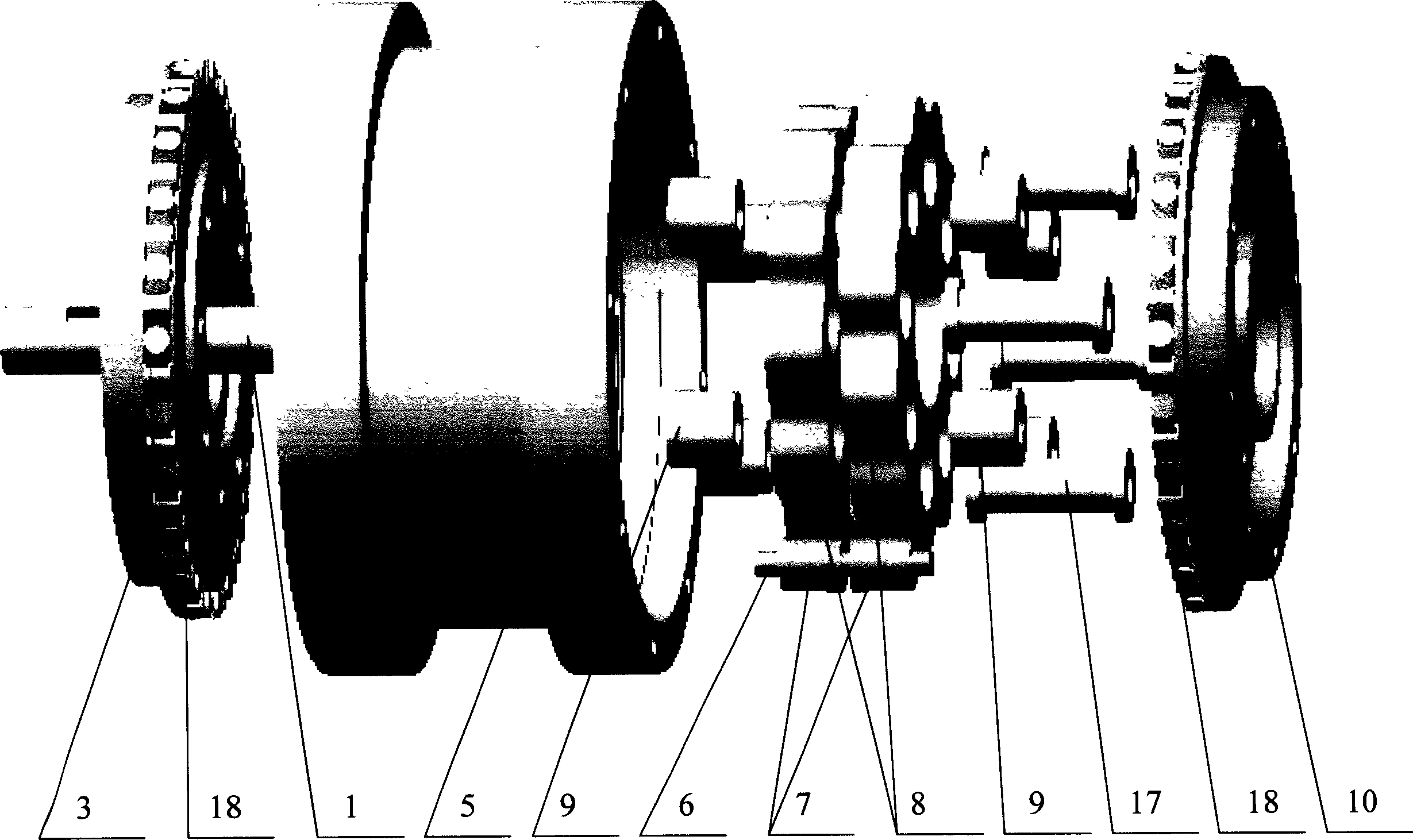

[0024] exist figure 1 Among them, the left and right disks 3 and 10 are respectively located in the symmetrical step-shaped circular holes at the left and right ends of the main body 5, and the outer surfaces of the left and right ends of the left and right disks 3 and 10 have symmetrical annular stepped surfaces. The annular stepped surface on the outer surface of the right end of the disk 3 and the annular stepped surface on the outer surface of the left end of the right disc 10 are respectively equipped with rollers 18 arranged at intervals in the axial and radial directions, that is, special radial / axial bearings or cone bearings. The roller bearing replaces the roller, and the roller is movably matched with the corresponding end surface and the corresponding inner wall of the step-shaped circular hole in the left and right ends of the main body 5; The ring-shaped groove surrounded by the ring-shaped step surface on the outer surface of the outer surface and the inner wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com