Patents

Literature

48results about How to "Good meshing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cup-shaped harmonic gear with common tangent type double-circular arc tooth profile and tooth profile design method of gear

ActiveCN104074948AImprove mechanical propertiesGood meshing effectPortable liftingGearing elementsHarmonicEngineering

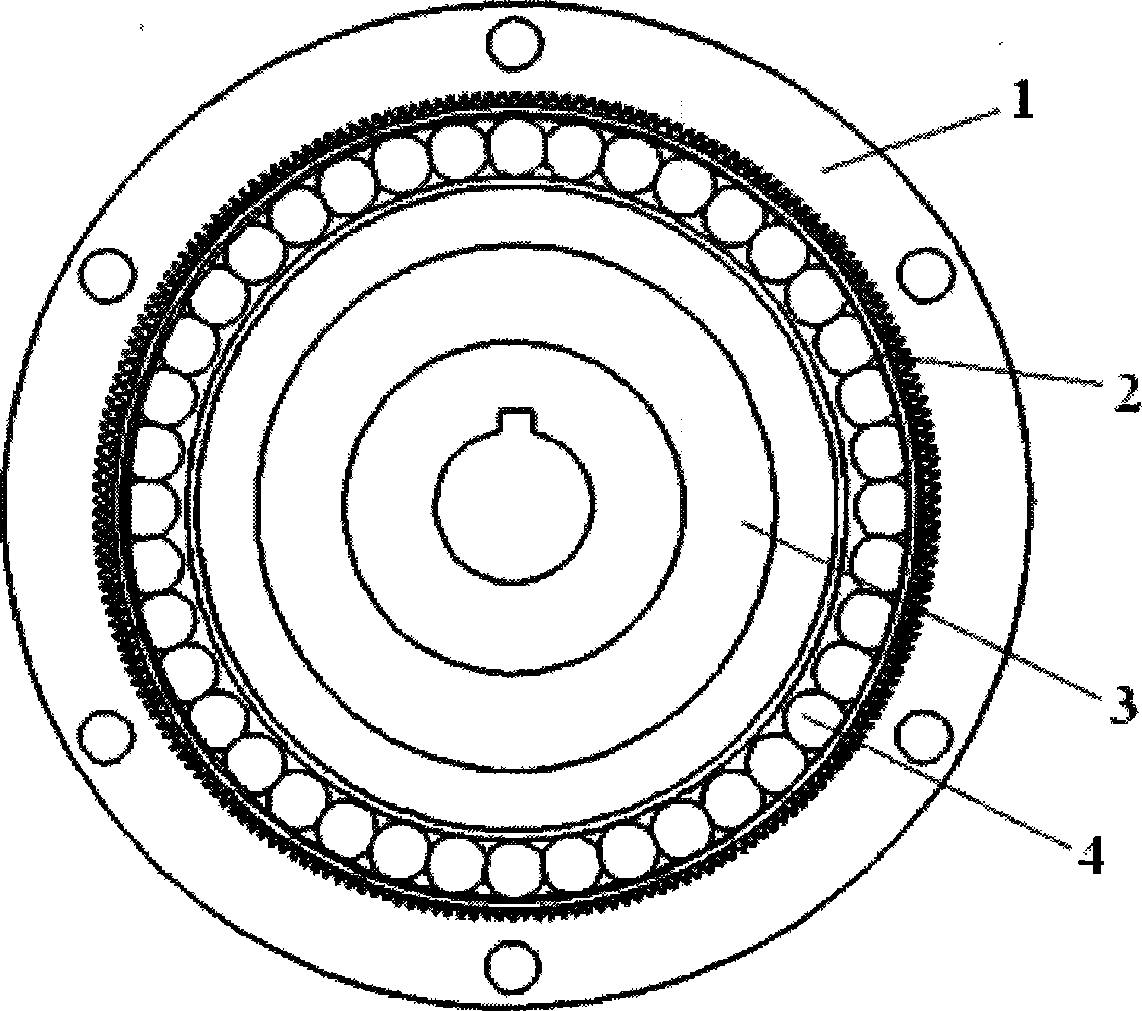

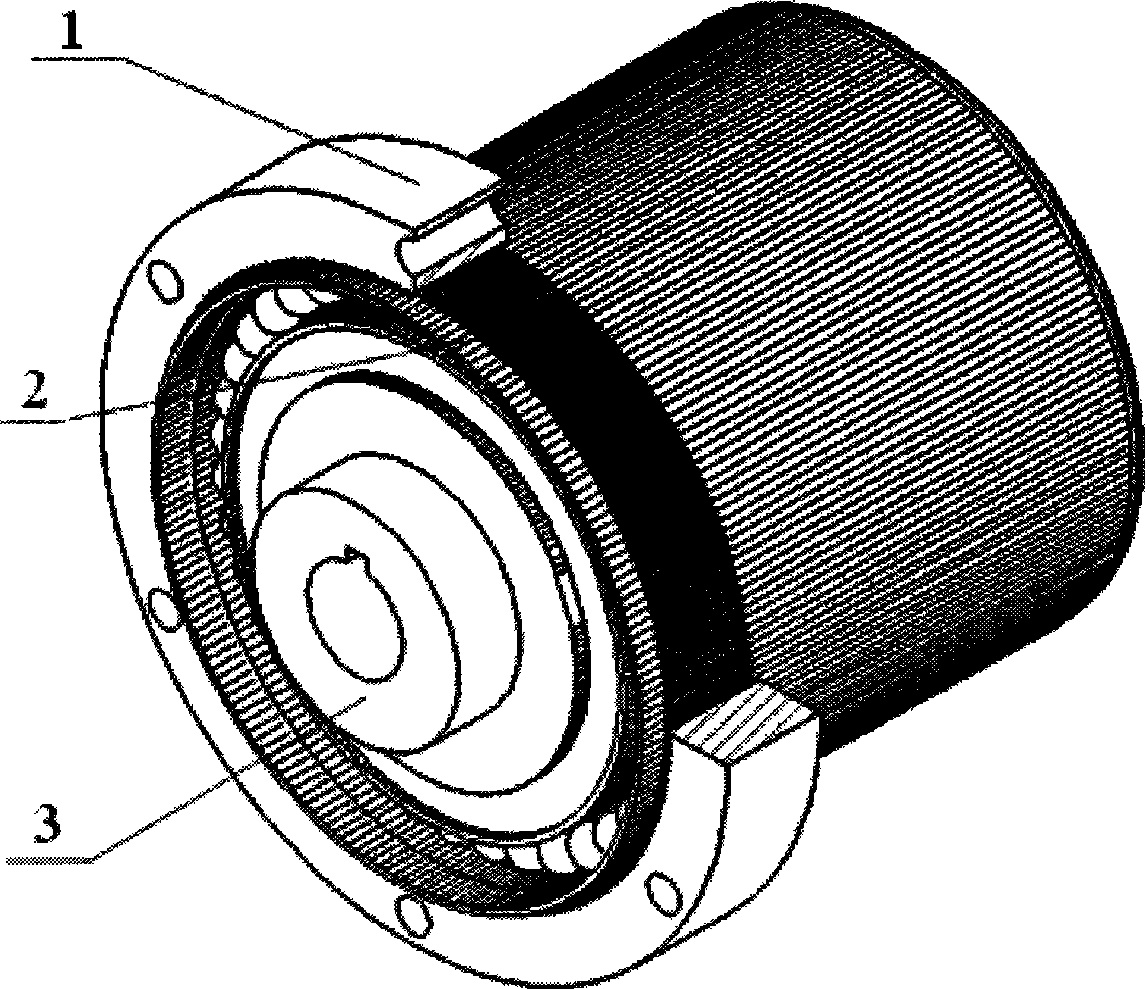

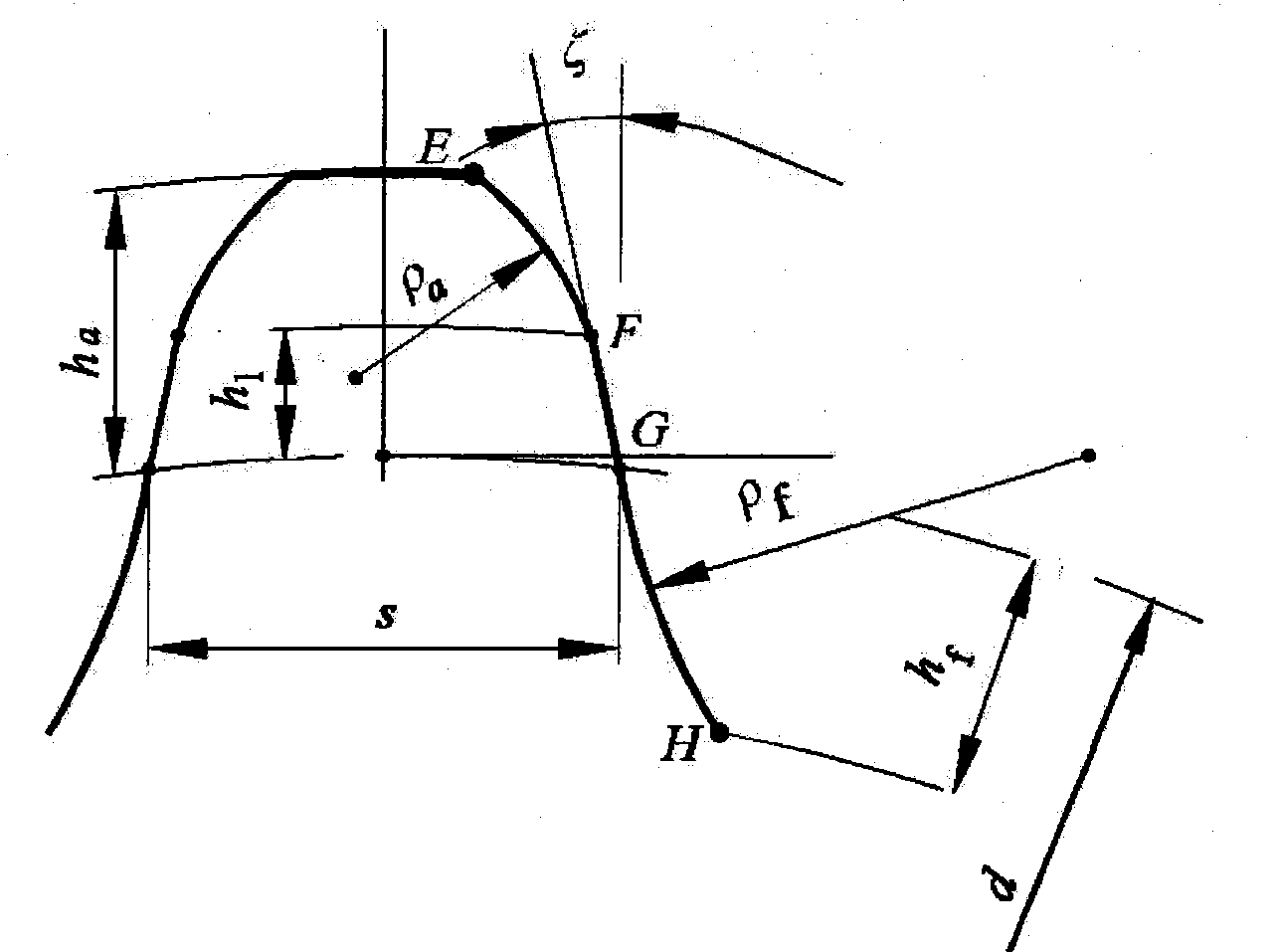

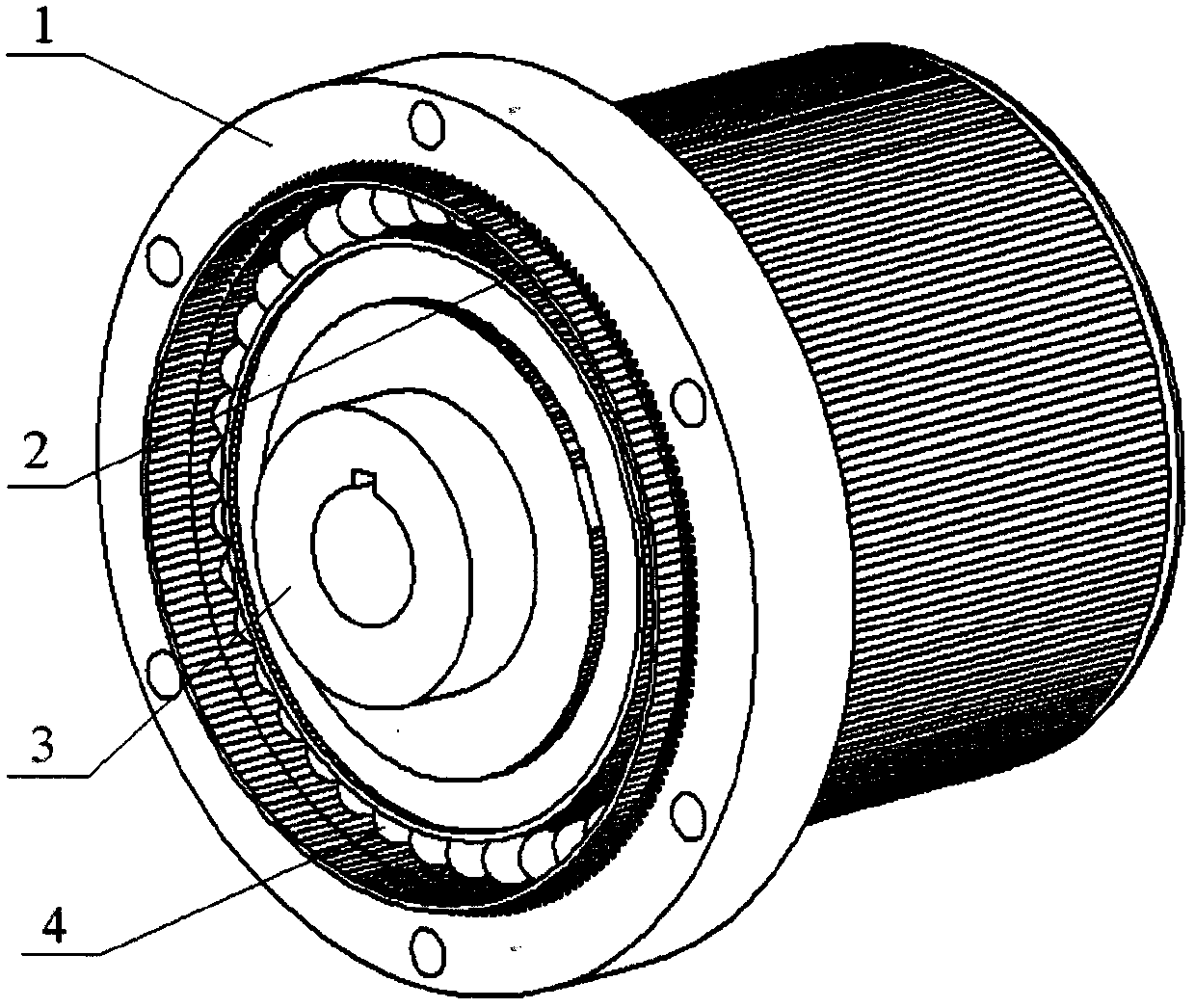

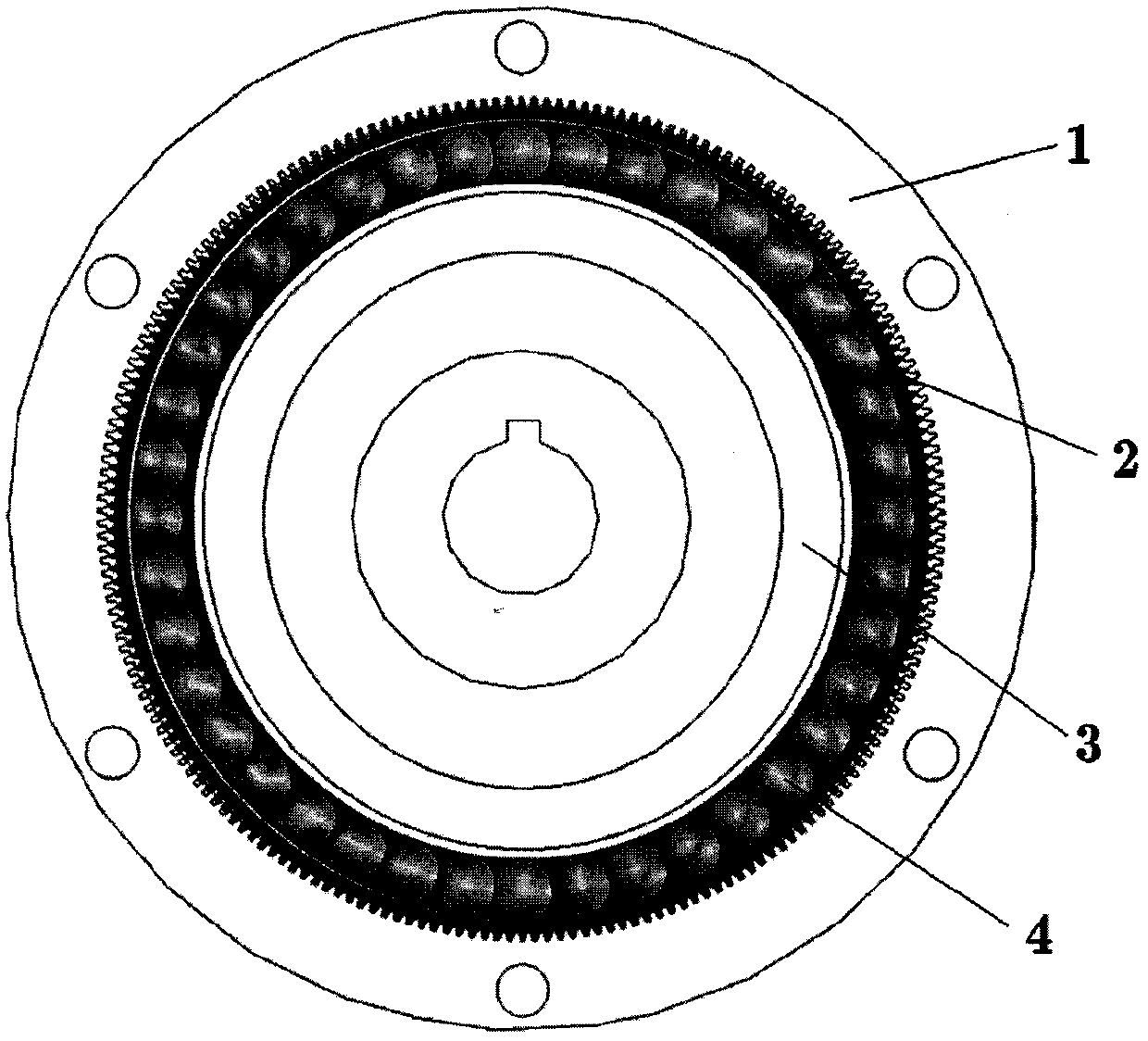

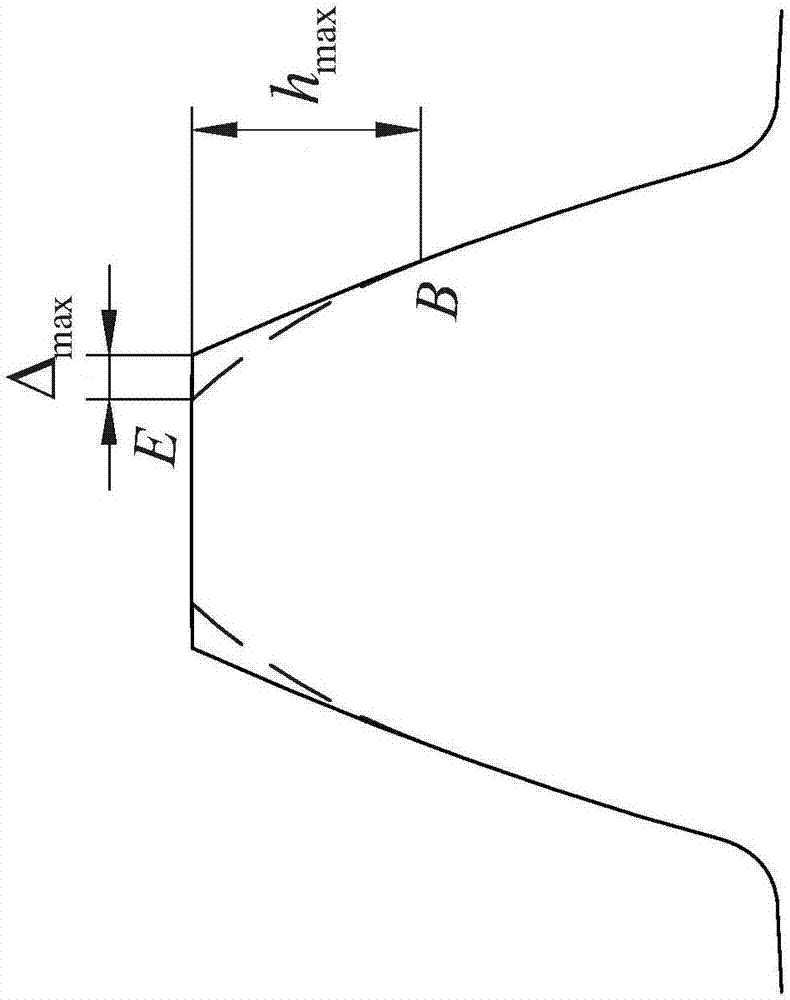

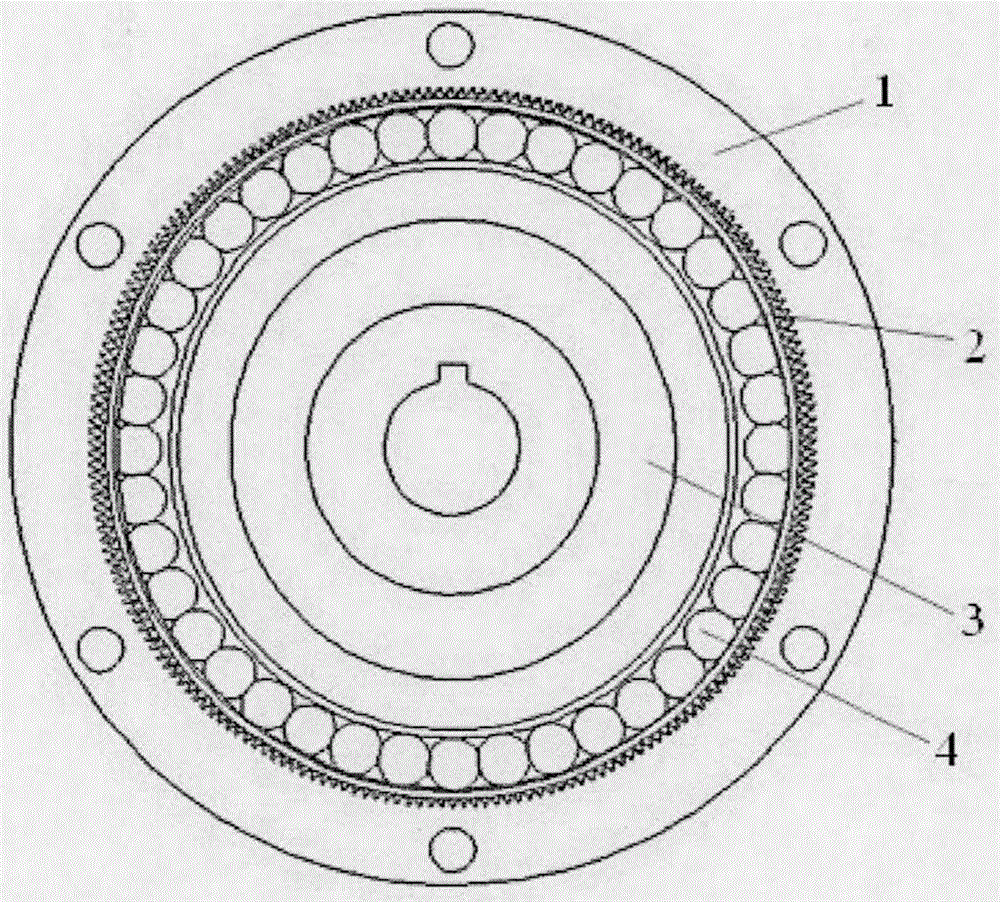

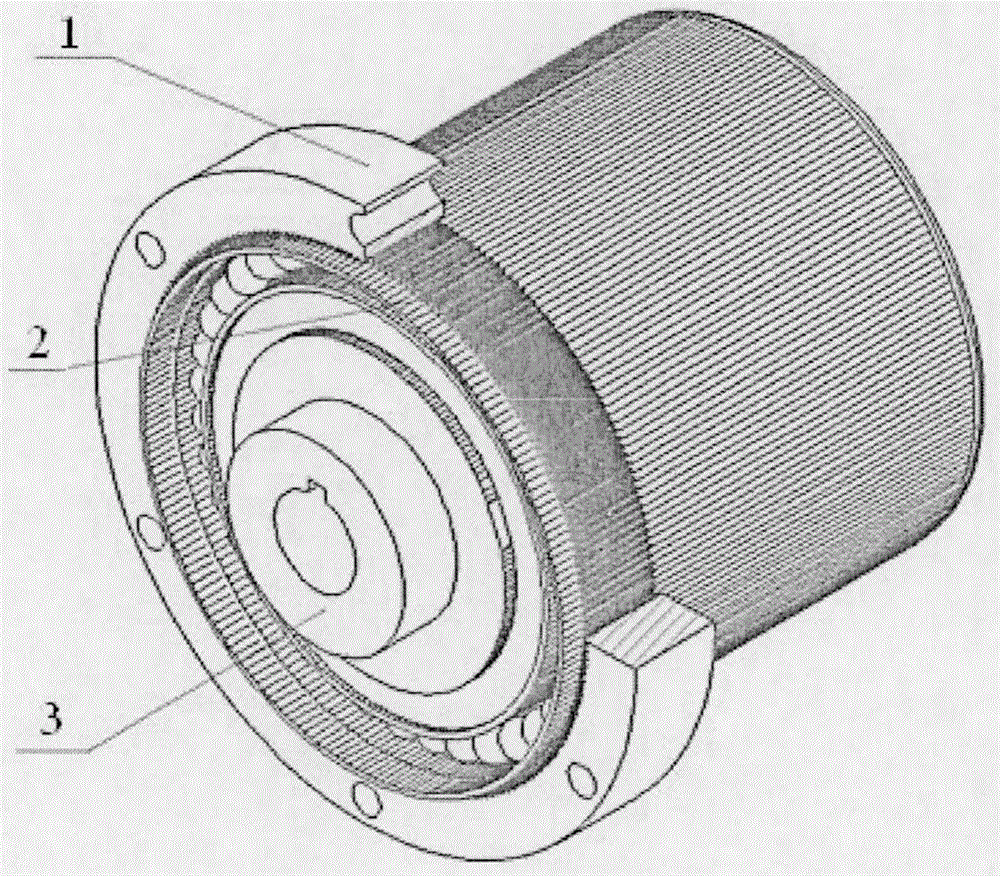

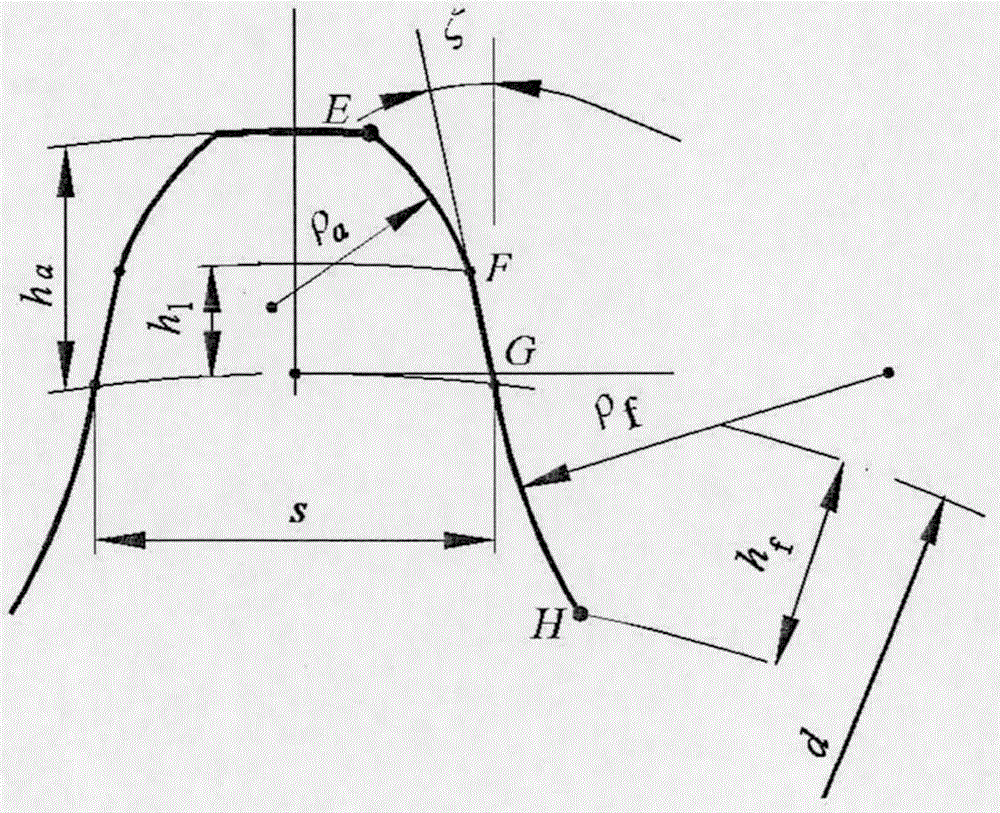

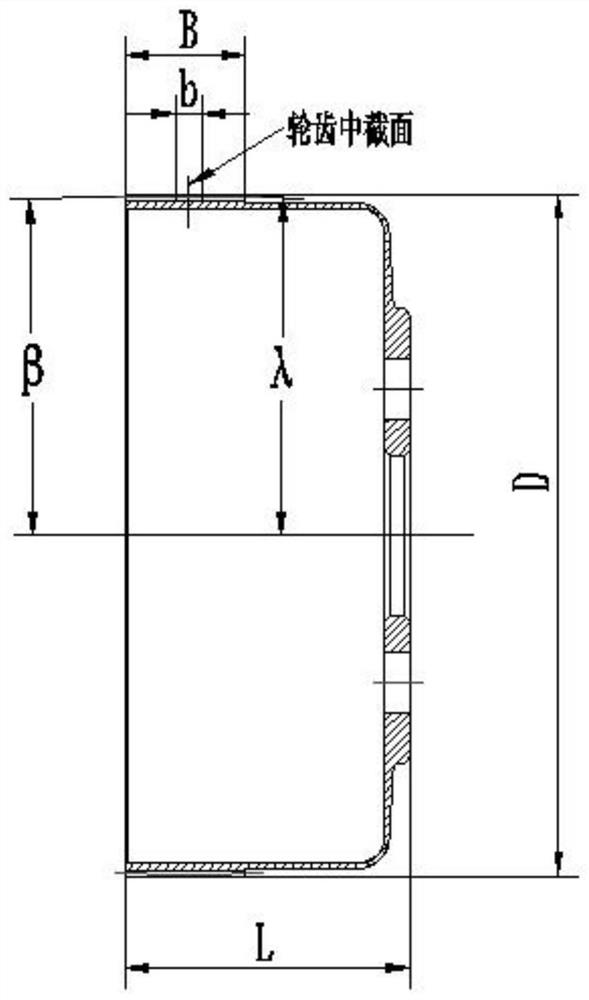

The invention provides a cup-shaped harmonic gear with a common tangent type double-circular arc tooth profile. The cup-shaped harmonic gear is composed of a wave generator, a flexible gear and a rigid gear; the tooth profiles of the flexible gear and the rigid gear of the harmonic gear transmission are common tangent type double-circular arc plane tooth profile. The invention also provides a tooth profile design method of the cup-shaped harmonic gear with the common tangent type double-circular arc tooth profile; the tooth profile design method comprises taking the coning deformation of the cup-shaped flexible gear in the axial direction into account, and in order to avoid interference, performing enveloping and fitting calculation on the circular arc part of the tooth root of the rigid gear by use of the movement locus of the gear teeth of the front section of the flexible gear according to the maximum radial deformations on the front, middle and rear sections of the flexible gear and the movement locus difference of the gear teeth of the flexible gear relative to the tooth groove of the rigid gear, and performing enveloping and fitting calculation on the circular arc part of the tooth crest of the rigid gear by use of the movement locus of the gear teeth of the rear section of the flexible gear so that the flexible gear and the rigid gear are in continuous conjugate transmission in the entire engagement interval. The cup-shaped harmonic gear with the common tangent type double-circular arc tooth profile has the advantages of increased number of engaged teeth, increased engagement contact surface, high bearing capacity, long fatigue life and the like.

Owner:TIANJIN POLYTECHNIC UNIV

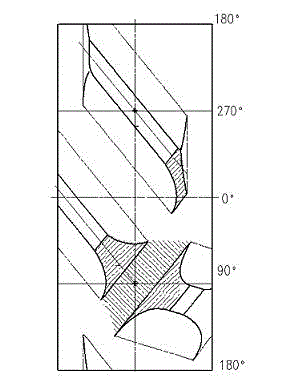

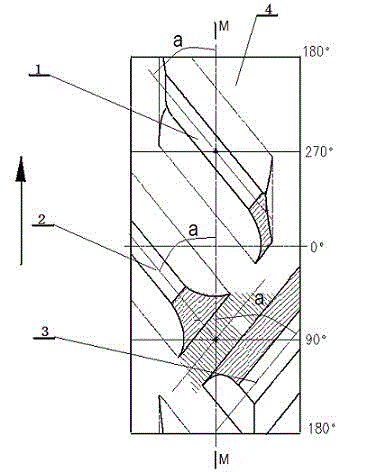

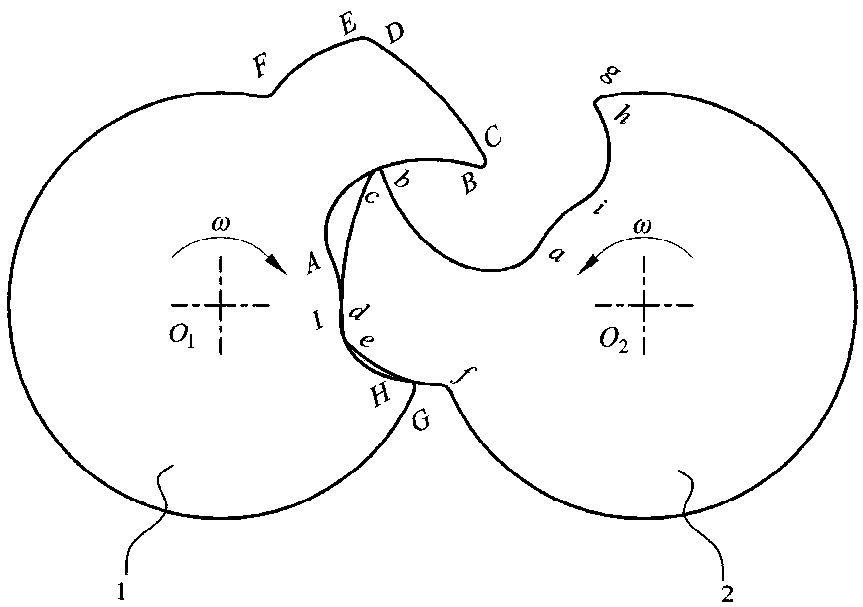

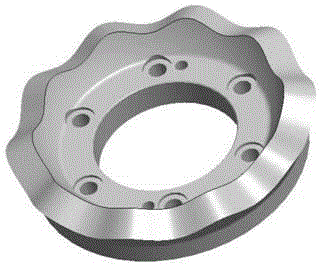

Design for three-circular-arc tooth profiles of continuous conjugate cup-shaped or silk-hat-shaped harmonic gear

ActiveCN107191570AImprove carrying capacityHigh transmission precisionSustainable transportationGearingGear wheelRooted tooth

The invention provides a cup-shaped or silk-hat-shaped harmonic gear with three-circular-arc tooth profiles in consideration of the axial taper deformation of a flexible gear body. The cup-shaped or silk-hat-shaped harmonic gear is composed of a rigid gear body, the flexible gear body and a wave generator; the flexible gear body is a straight-tooth cylindrical external gear body with the three-circular-arc tooth profile; and the rigid gear body is a straight-tooth cylindrical inner gear body with the three-circular-arc tooth profile. The invention further provides a design method for the tooth profiles of the cup-shaped or silk-hat-shaped harmonic gear with the three-circular-arc tooth profiles. According to the design method, parameters of the three-circular-arc tooth profile of the flexible gear body are selected according to the design criterion that the envelope existence interval is the largest on a design section; the circular-arc tooth profiles of a tooth root and a tooth top of the rigid gear body adopt outer envelope fitting calculation of the movement tracks of the tooth profile of the flexible gear body on the front cross section and the rear cross section of a gear ring of the flexible gear body; and a middle section adopts circular-arc fitting so as to improve the fitting flexibility of the tooth profiles. Compared with a harmonic gear with double-circular-arc tooth profiles, the harmonic gear with the three-circular-arc tooth profiles has a wider envelope existence interval, a wider conjugate meshing tooth surface and a more uniform backlash, and therefore the bearing capacity and the transmission precision of the harmonic gear can be improved.

Owner:TIANJIN POLYTECHNIC UNIV

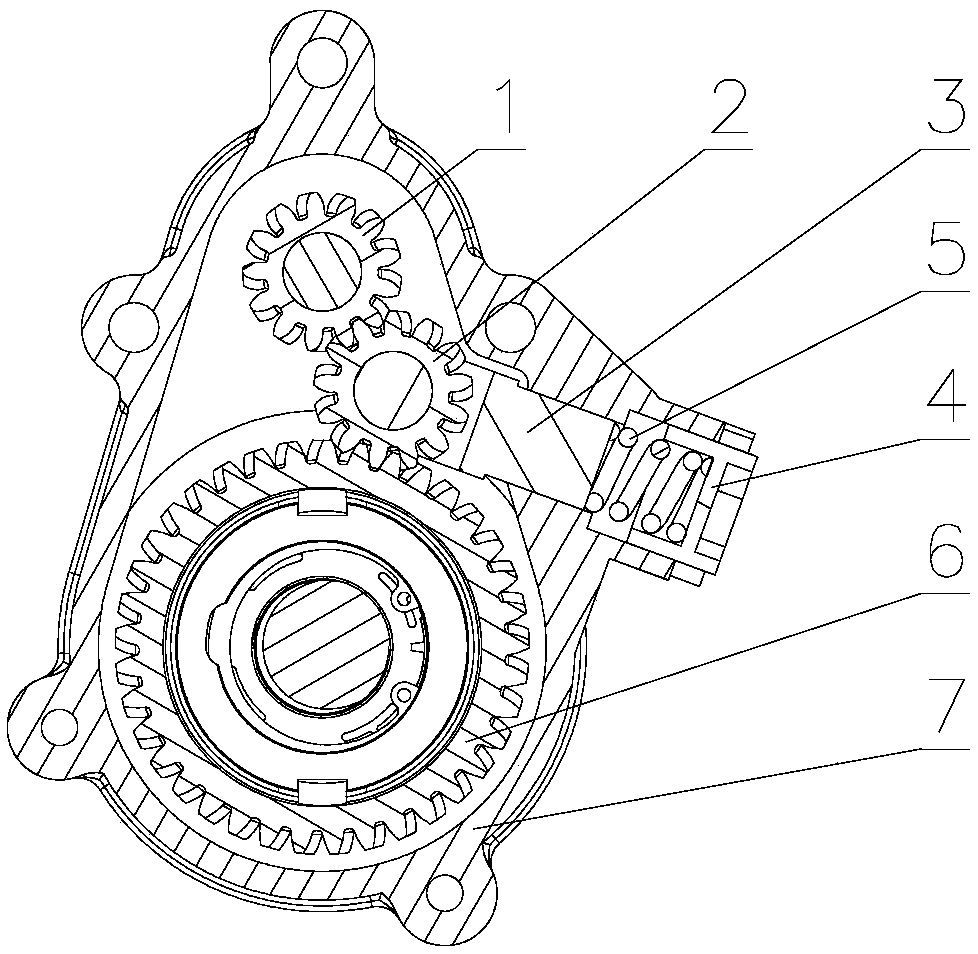

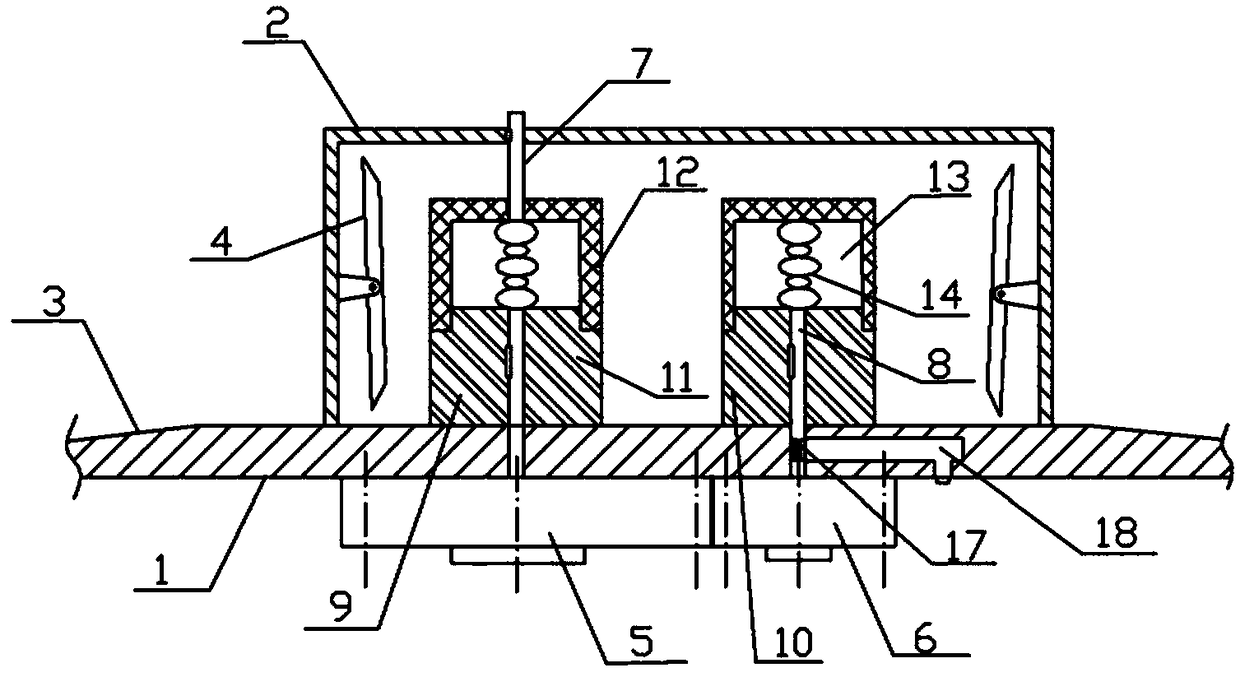

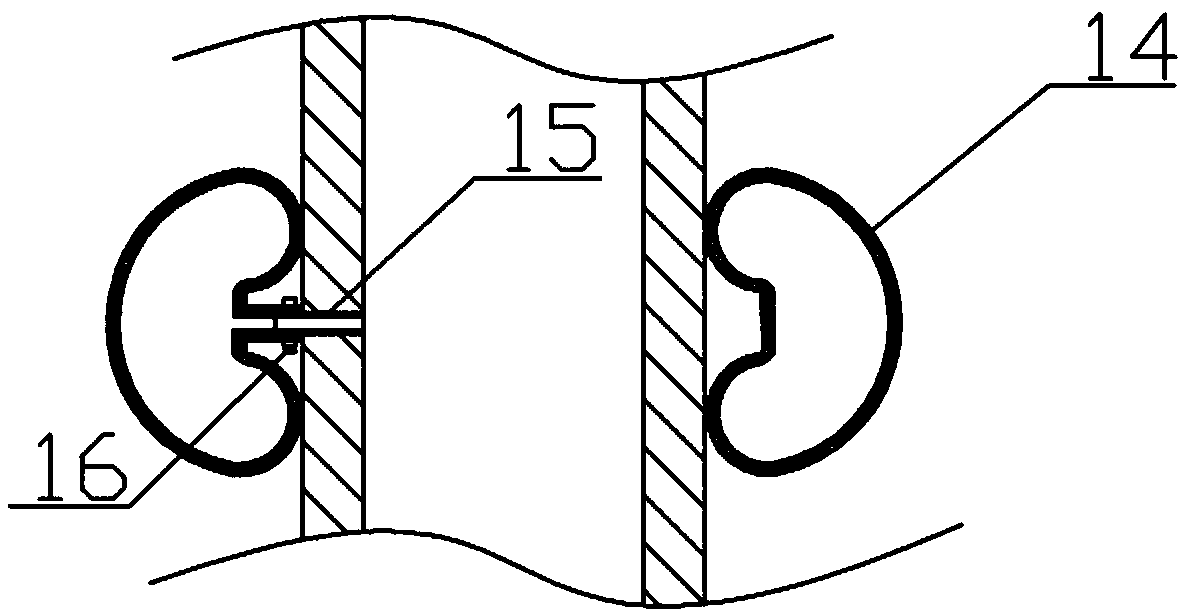

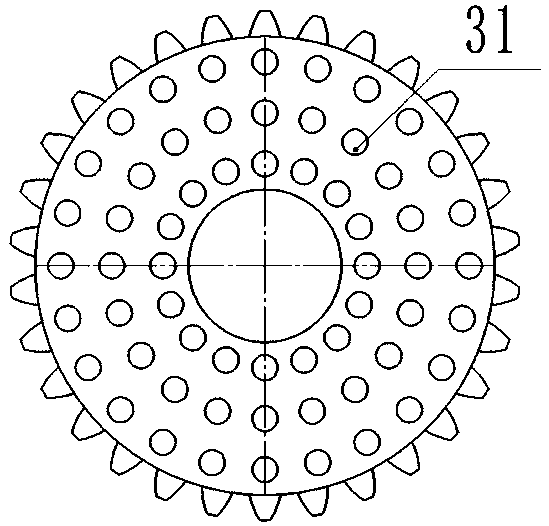

Engagement rotor of internal mixer

ActiveCN102941633AIncrease the lengthIncrease the space for back and forthRubber materialEngineering

The present invention discloses an engagement rotor of an internal mixer, including a rotor body (4) and three ribs disposed on the rotor body (4). The three ribs are respectively of a long rib (1), a middle rib (2) and a short rib (3). The rotor is characterized in that: the long rib (1) and the middle rib (2) are same in the spiral direction, and the spiral direction of the short rib (3) is opposite to that of the long rib (1) and the middle rib (2). According to the engagement rotor of the internal mixer, the spiral direction and the angle of the short rib are changed, and the length of the short rib is increased. Compared with a conventional structure, the shortcoming that the rubber material on short rib end face can not be stirred because of a dead zone in a conventional structure is overcome, the engagement area between two rotors is increased, and the rubber mixing effect is enhanced, so that the quality of the rubber material is further improved.

Owner:大连橡胶塑料机械有限公司

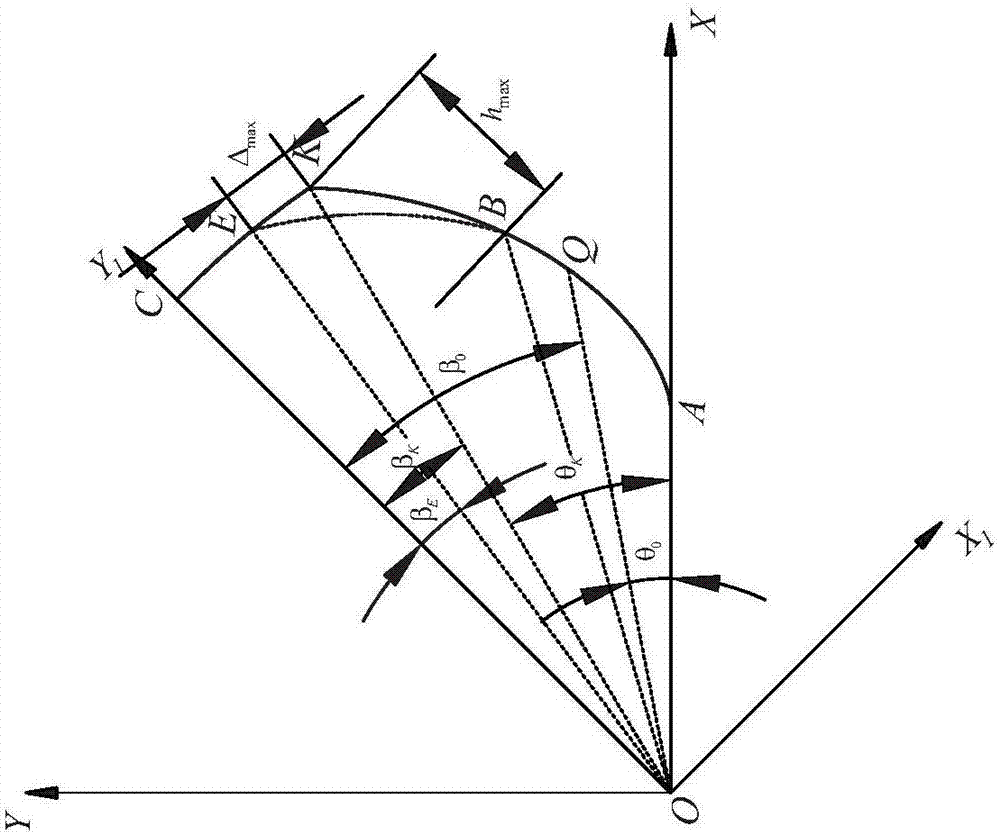

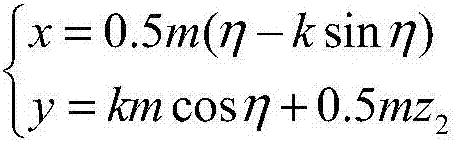

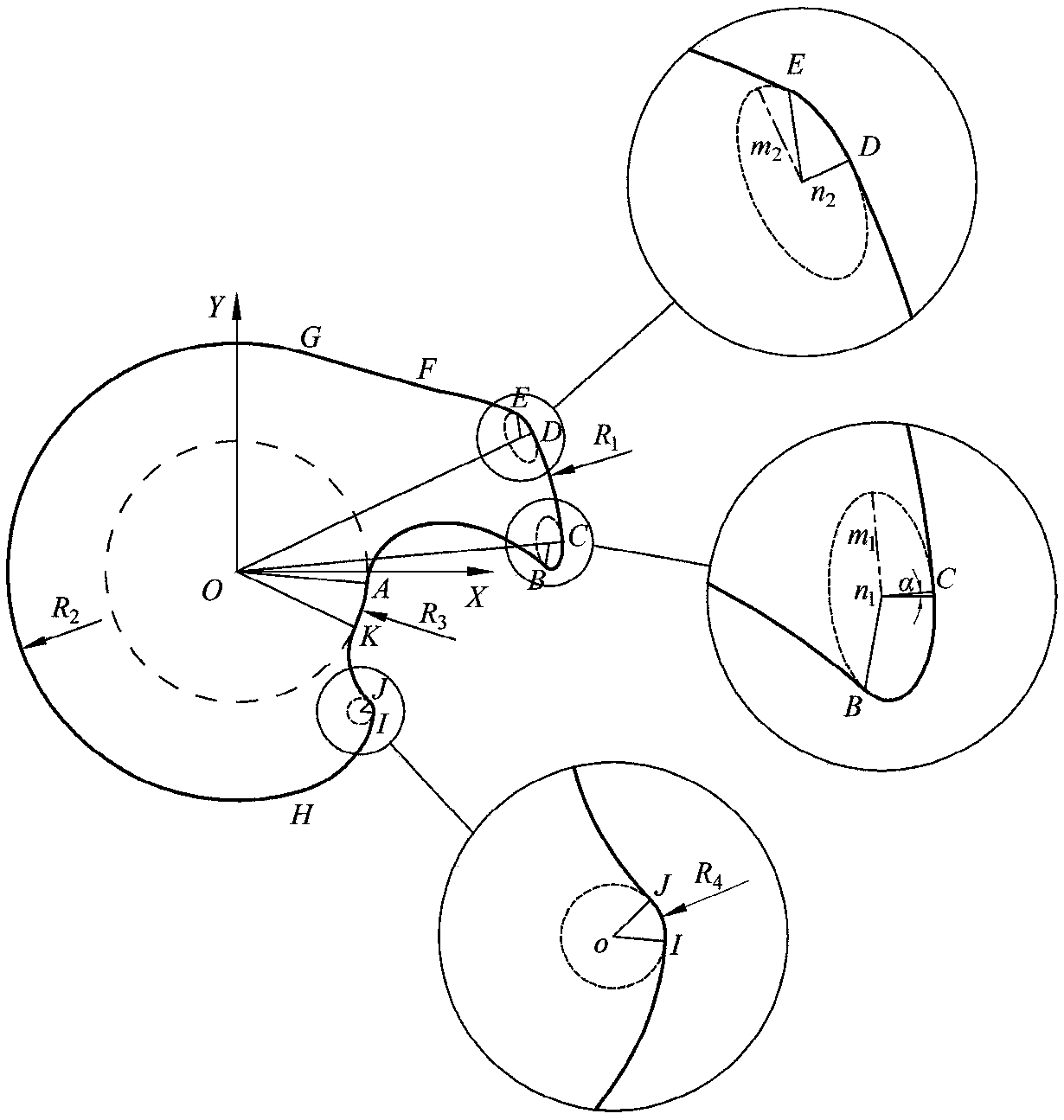

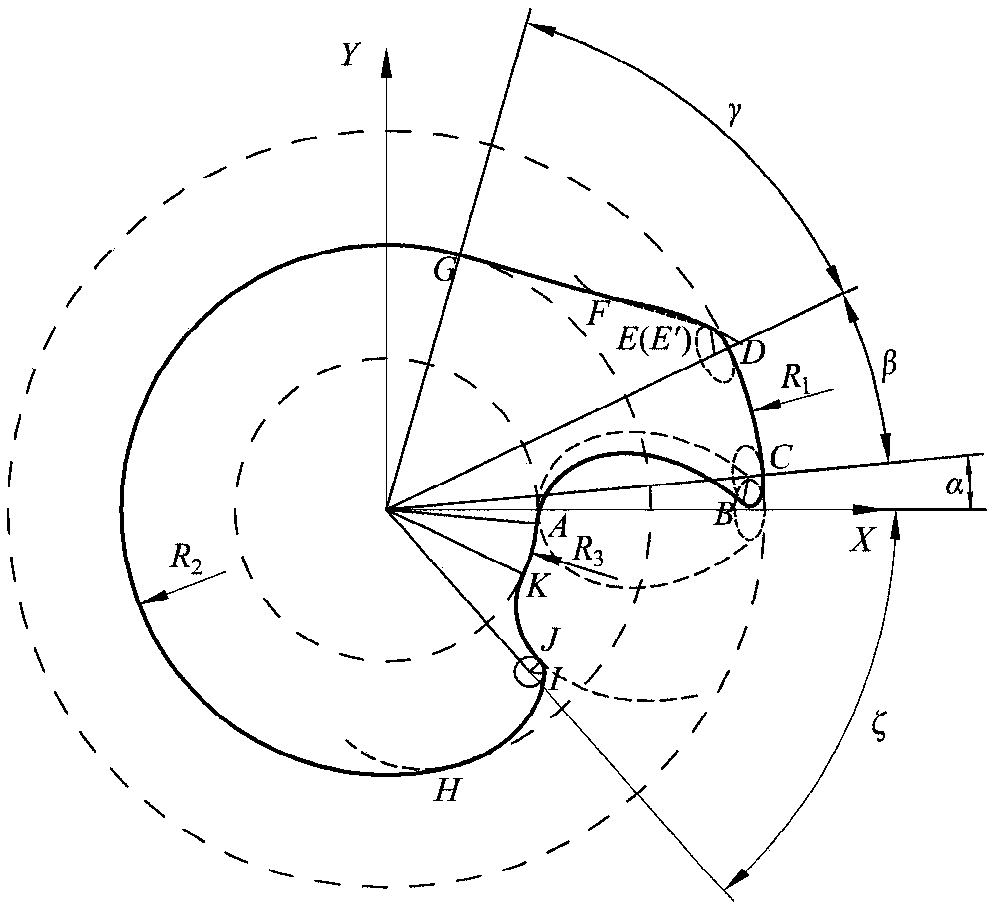

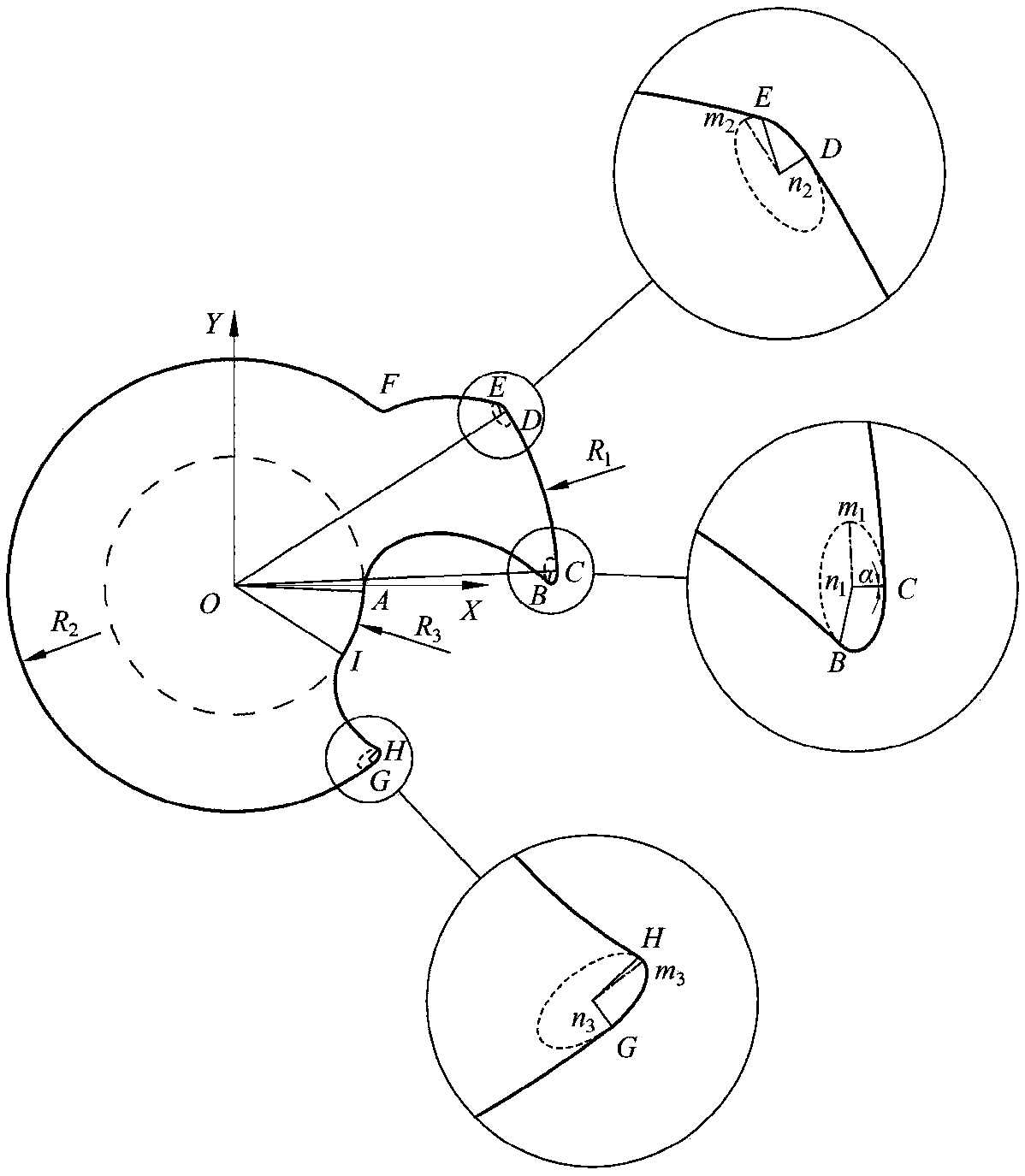

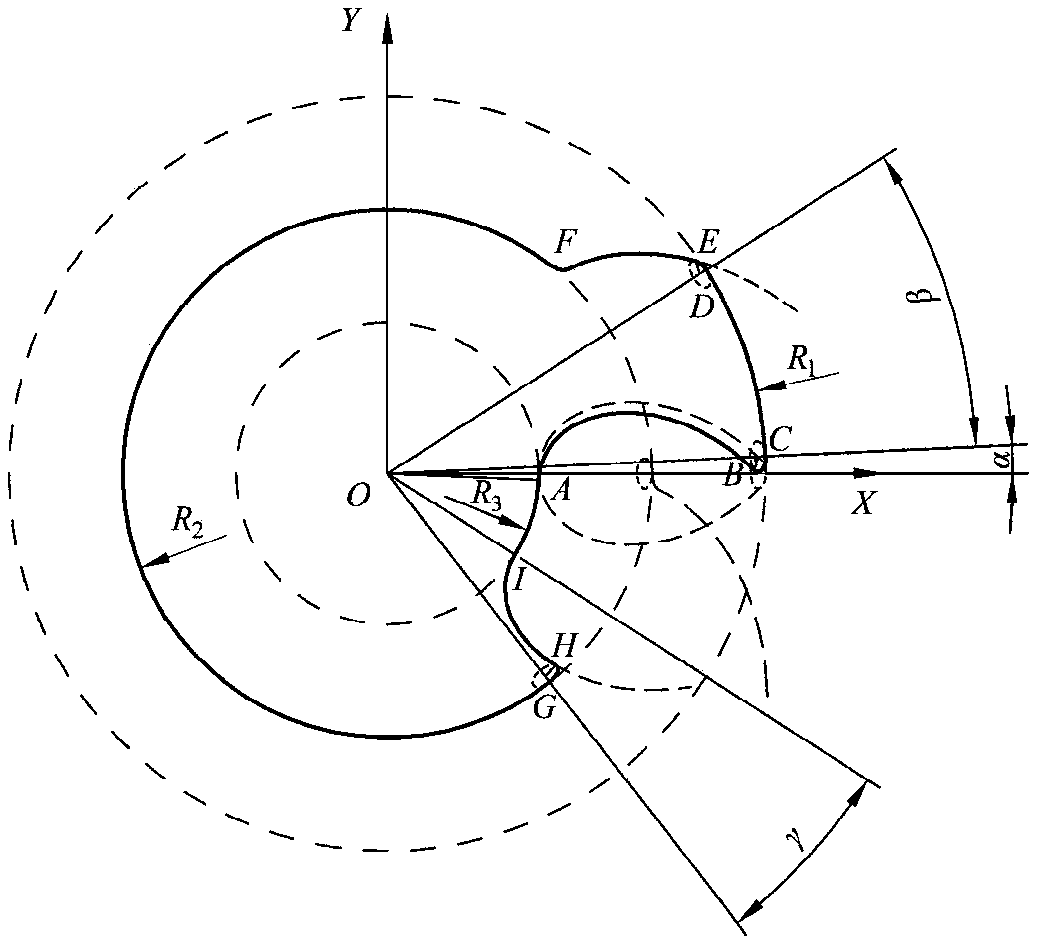

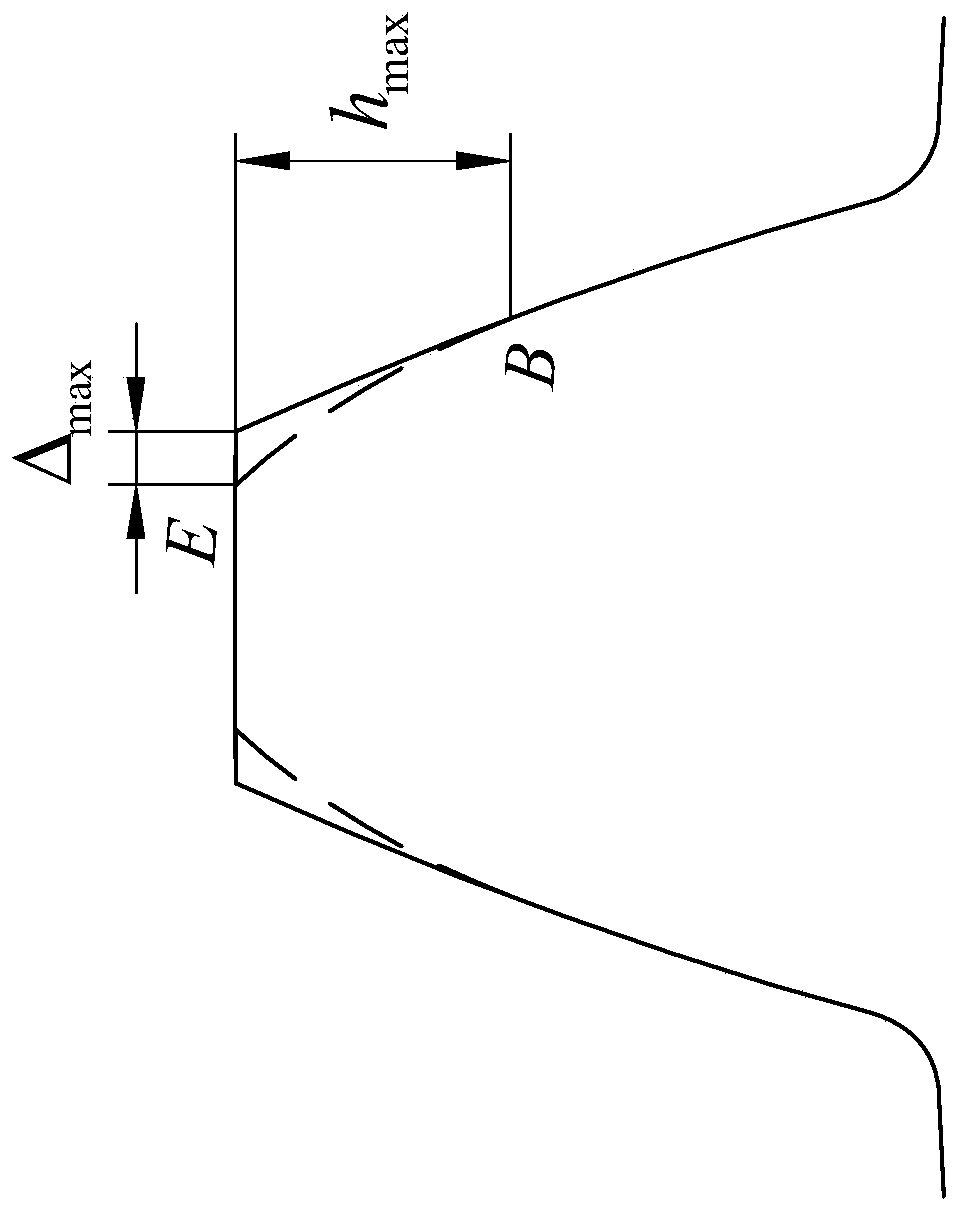

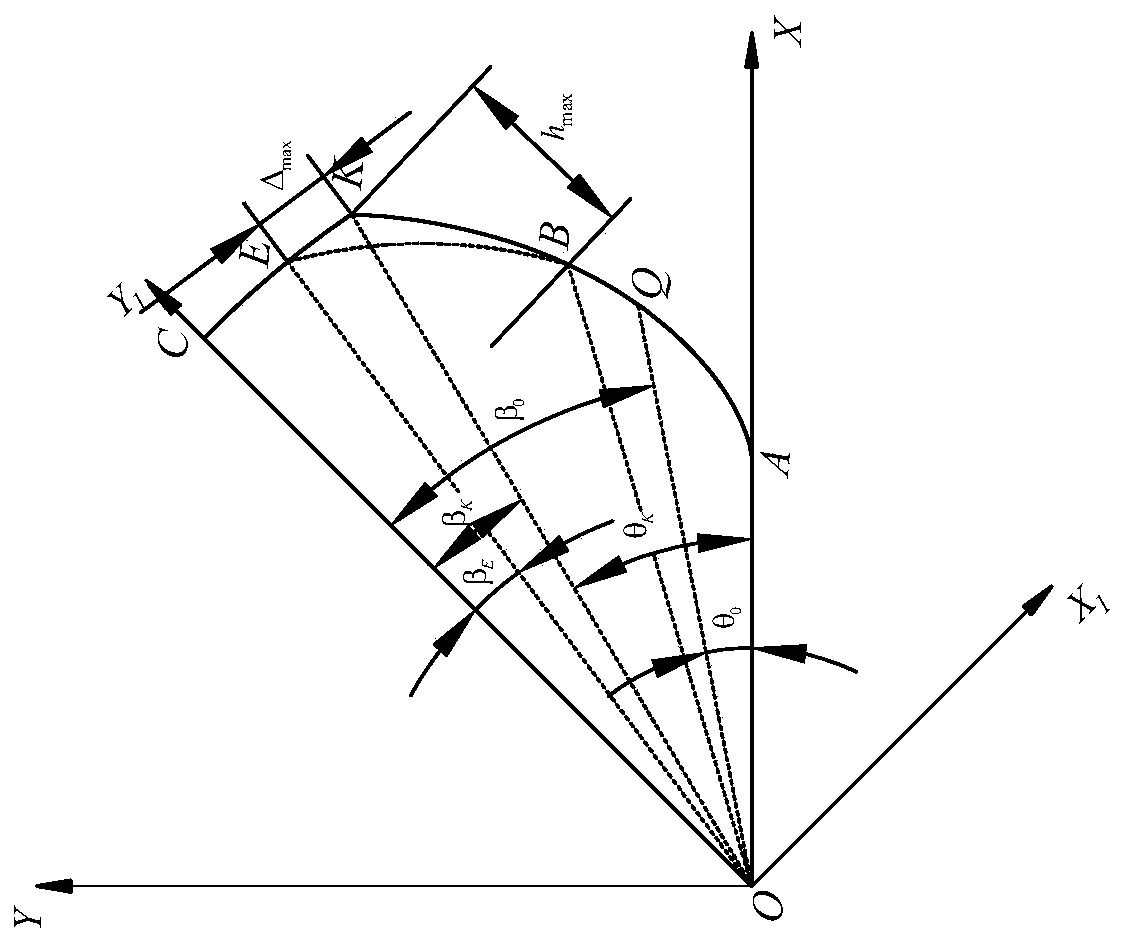

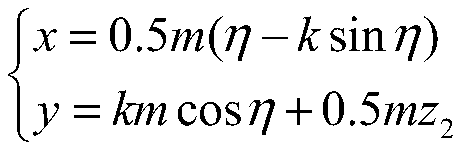

Modification method for harmonic driving involute profile

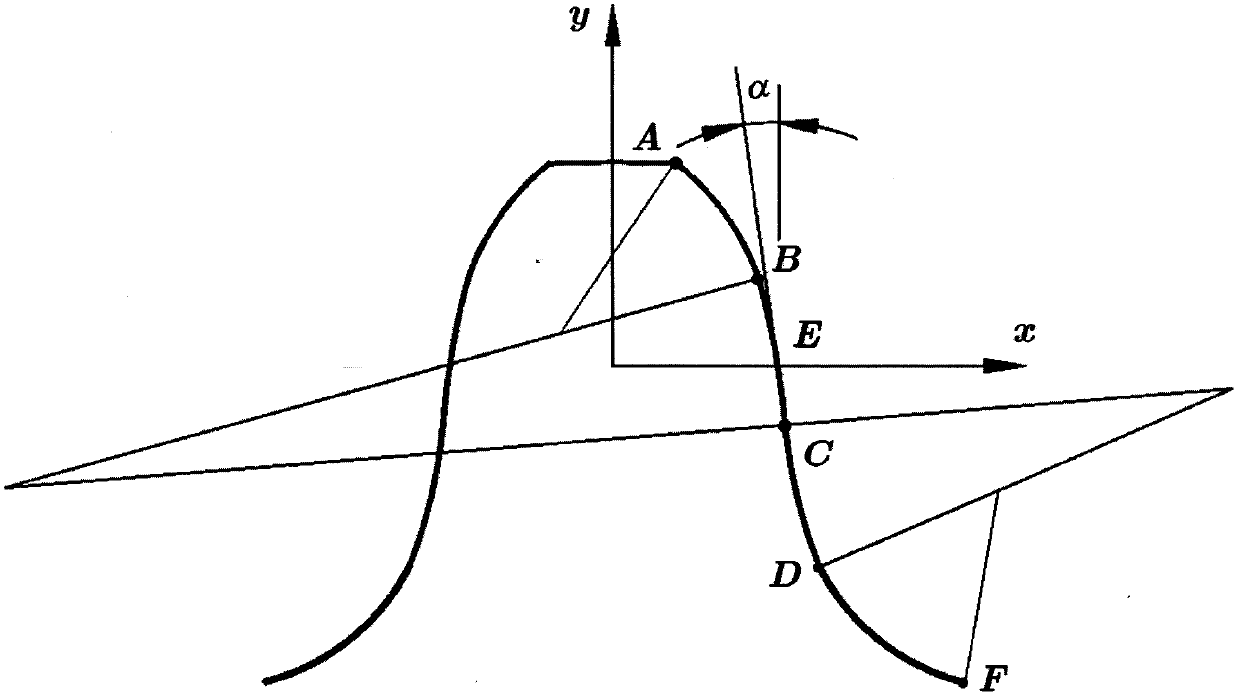

ActiveCN107882950AIncrease the number of teethSmall engagement backlashGearingPortable liftingKinematic theoryInvolute

The invention discloses a modification method for a harmonic driving involute profile. A point B serves as a point of tangency of a modification curve and a involute tooth surface. A point E serves asa point of intersection of the modification curve and an involute addendum circle. A coordinate system XOY is built with a radial OA as the abscissa axis. A coordinate system X1OY1 is built with a radial OC as the ordinate axis. After the steps of determining the coordinates of the point B and the point E in the coordinate system X1OY1 and the slope of a tangent of the involute at the point B, determining a flexible gear central point approximate movement track curvilinear equation, determining the parameter equation of the modification curve in the coordinate system X1OY1 and the like, a system of simultaneous equations is built and used for solving parameters, and the parameter equation of the modification curve in the coordinate system XOY is obtained through conversion of the coordinate system. According to the modification method, the harmonic driving involute profile is modified based on the harmonic driving kinematics theory, processing manufacturability and economy can be guaranteed, engagement performance is improved, the advantages of various harmonic tooth profiles are integrated, and the modification method can be widely applied to the technical field of harmonic gears.

Owner:国茂精密传动(常州)有限公司

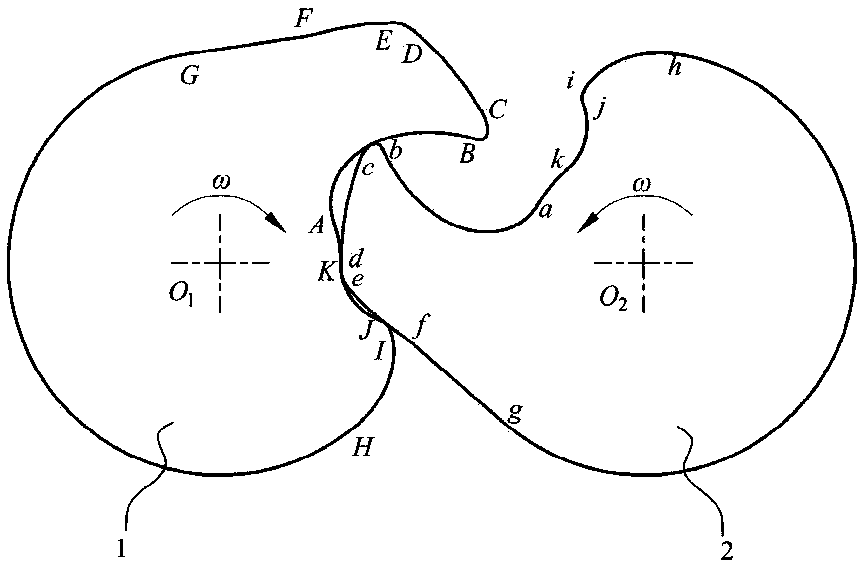

Straight jaw rotor of claw type vacuum pump and profile design method of straight jaw rotor

ActiveCN108757464AIncreased engagement rangeEngagement wire lengthGeometric CADRotary piston pumpsEllipseCycloid

The invention discloses a straight claw rotor of a claw type vacuum pump and a profile design method of the straight claw rotor. The straight claw rotor is composed of eleven segments of curves comprising four segments of arcs, two segments of elliptical arcs, two segments of elliptical arc envelope lines, one segment of equidistant curve of a cycloid, one segment of line segment and one segment of envelope line. The rotor uses the elliptical arcs and the envelope lines of the elliptical arcs to construct the profile at the top of a claw and the tip of the claw, and uses the arcs and the equidistant curve of the cycloid to construct the profile at the bottom of the claw, adjacent curves are all connected smoothly, no non-smooth connection point exists, and the mechanical properties, the meshing performance and the sealing performance of the straight jaw rotor are improved. Two rotors meshing with each other are identical and the correct meshing of the profile can be achieved. The rotorhas a smaller clearance volume and improves the compression ratio of the claw vacuum pump. The top of the claw is more flat, the meshing range is large, a mesh line is long, and abrasion is further reduced. The rotor enriches profile types of claw type rotors and promotes the development of claw type vacuum pumps.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

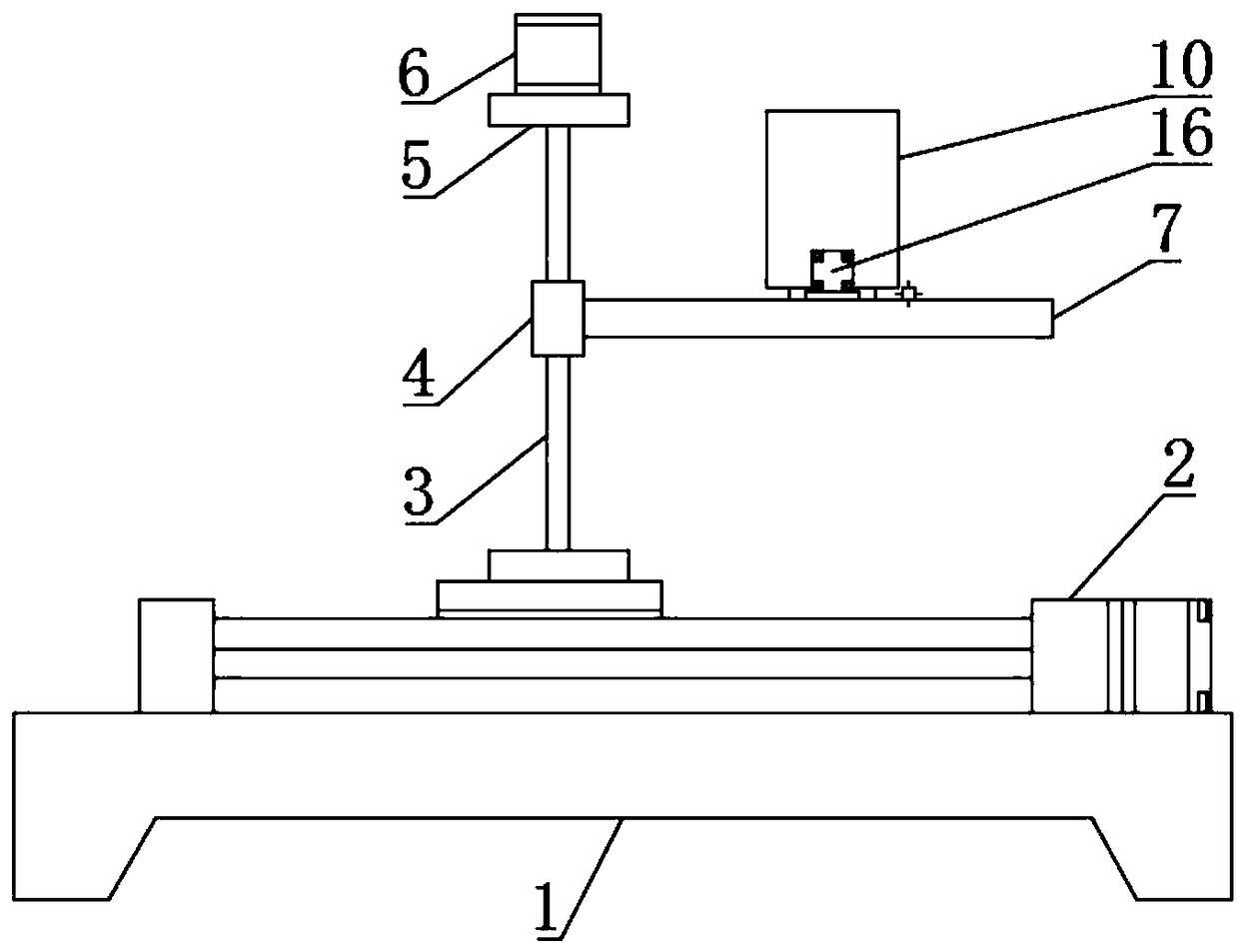

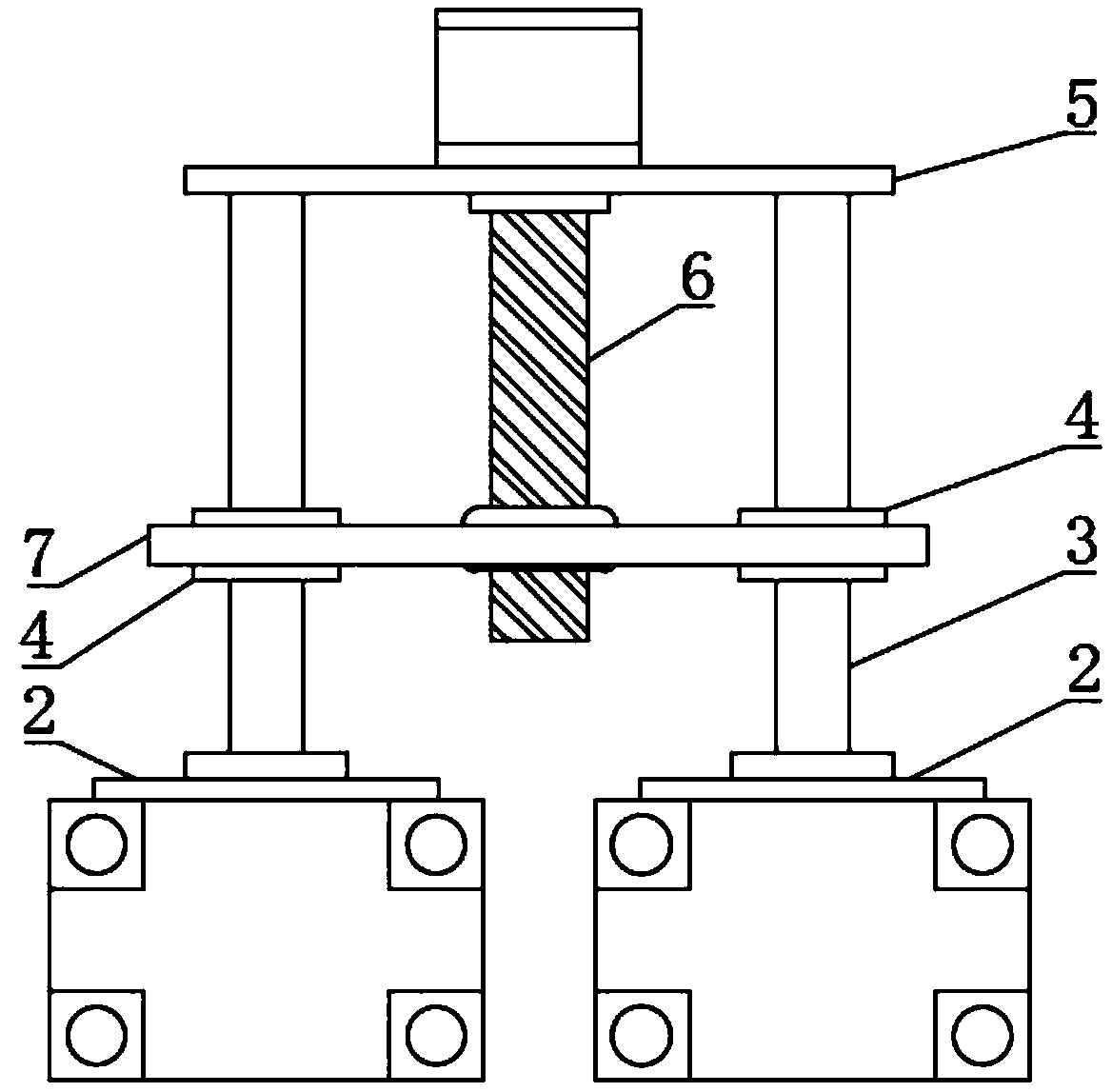

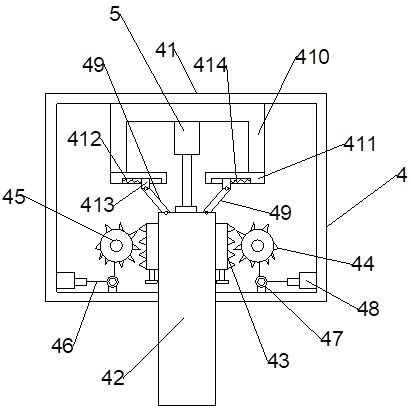

Gear sleeve machining device and machining method

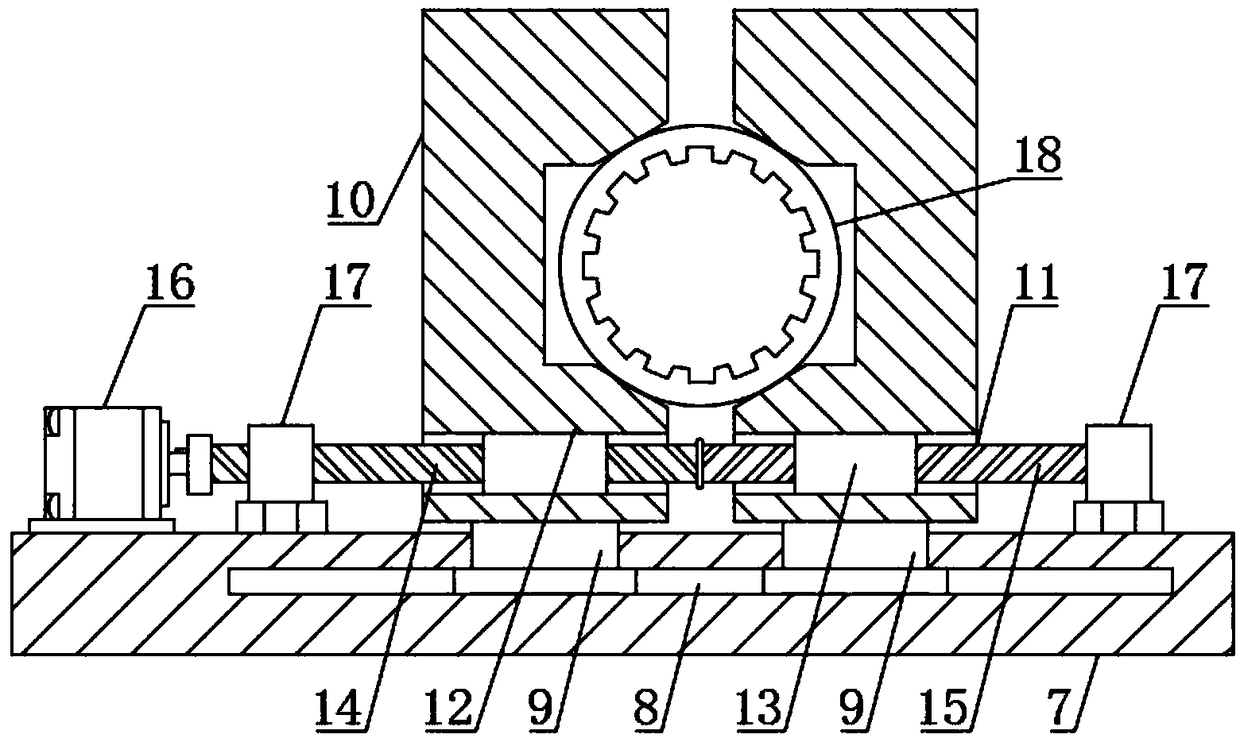

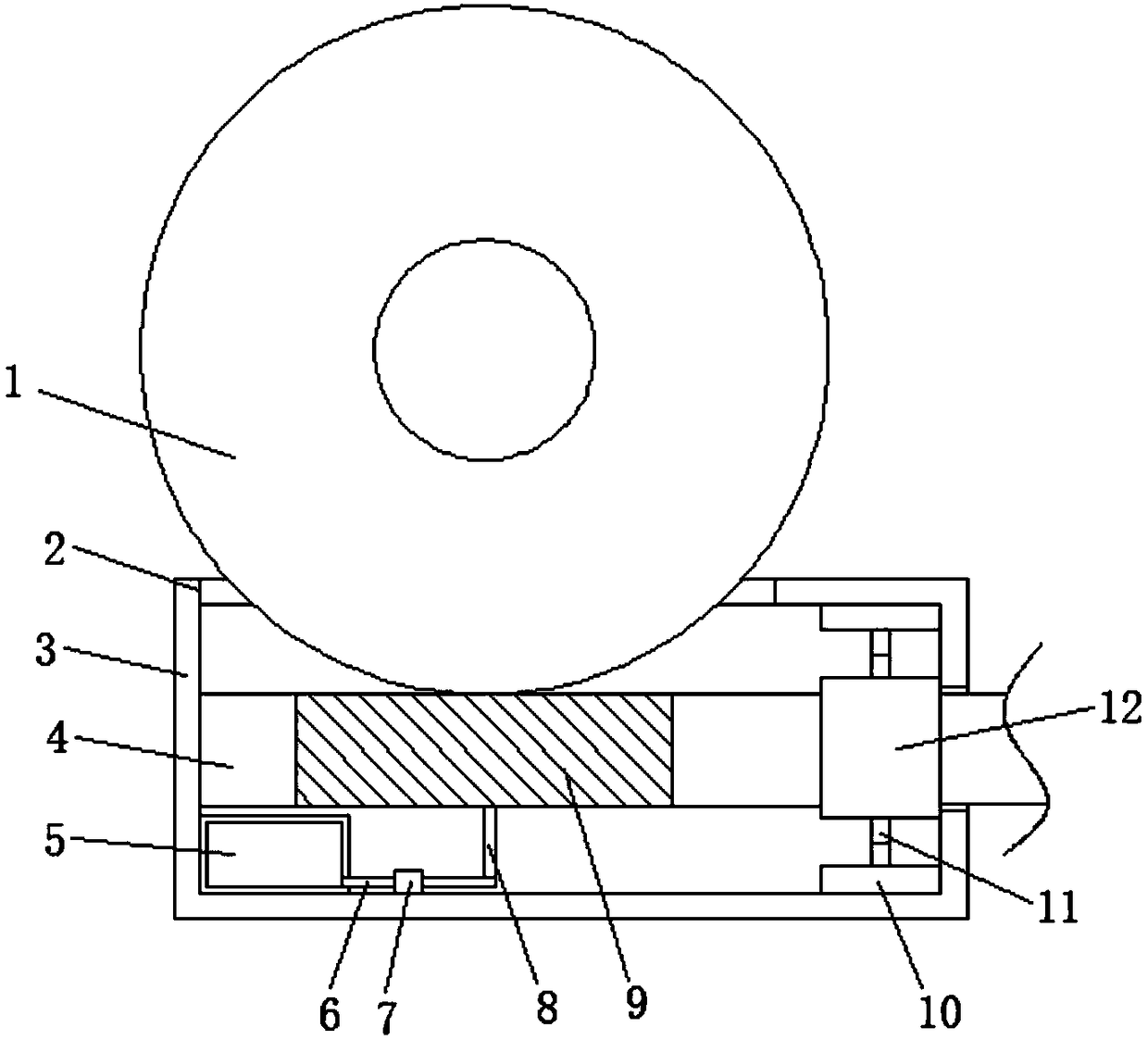

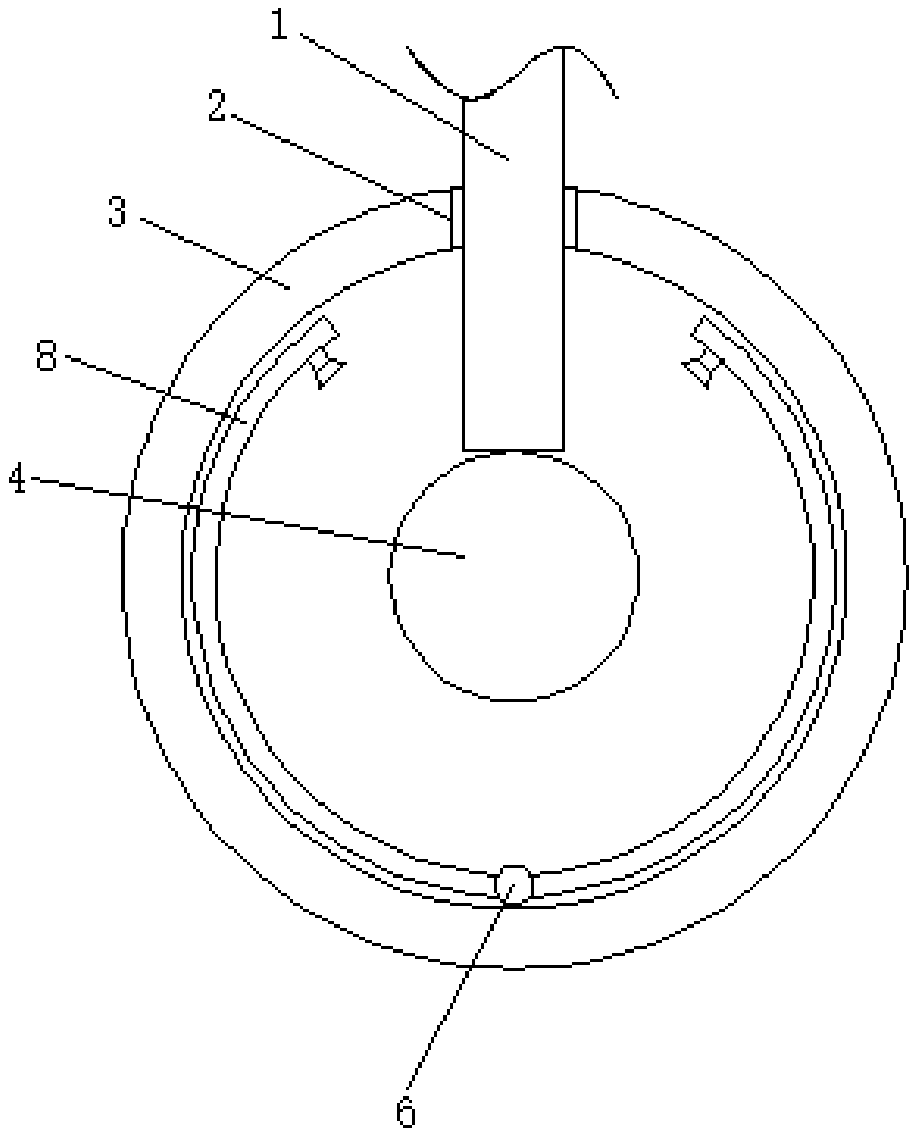

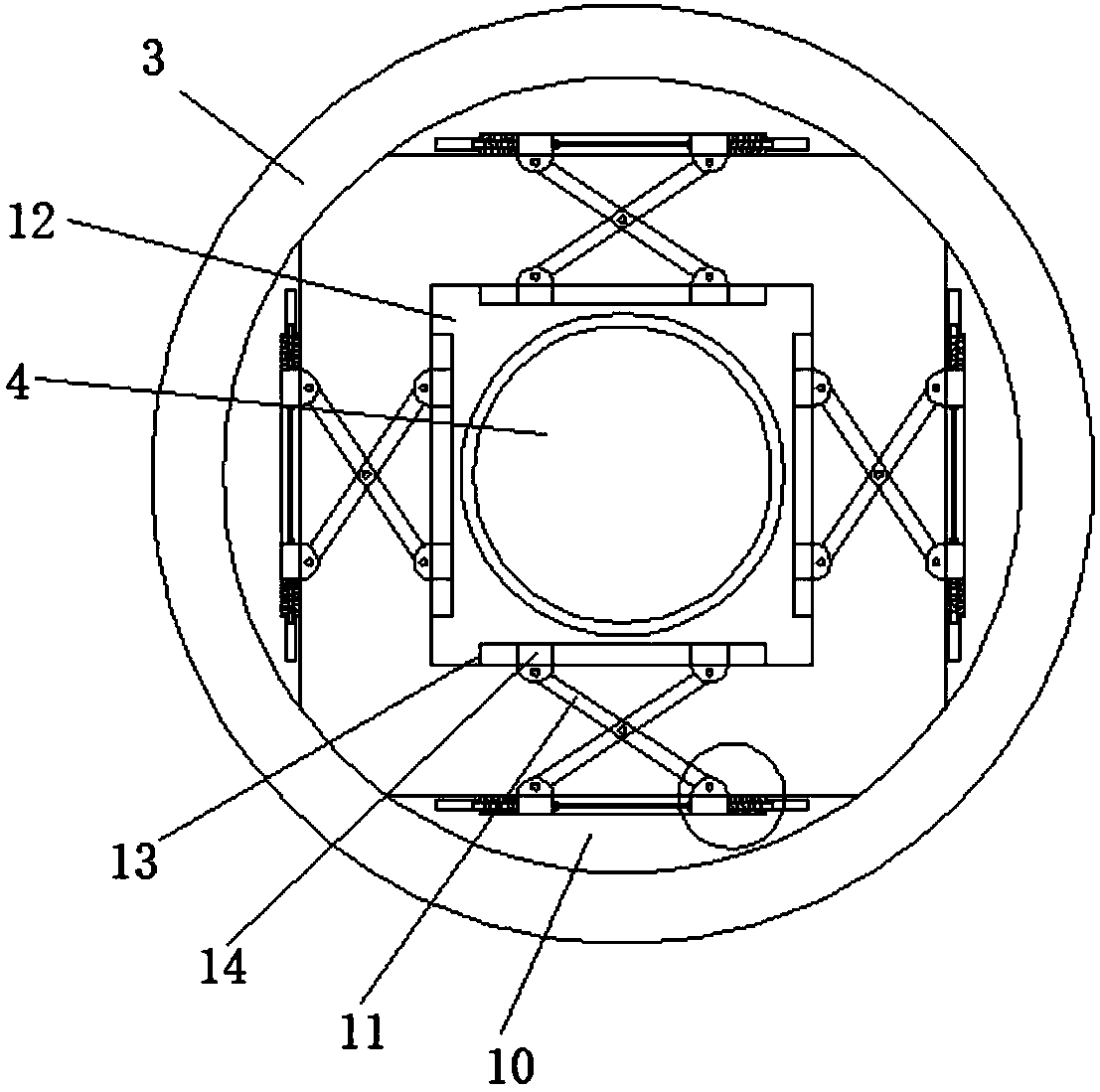

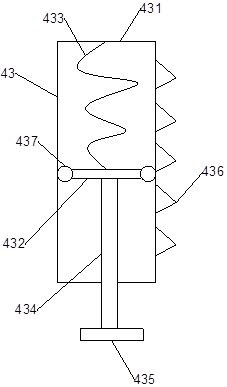

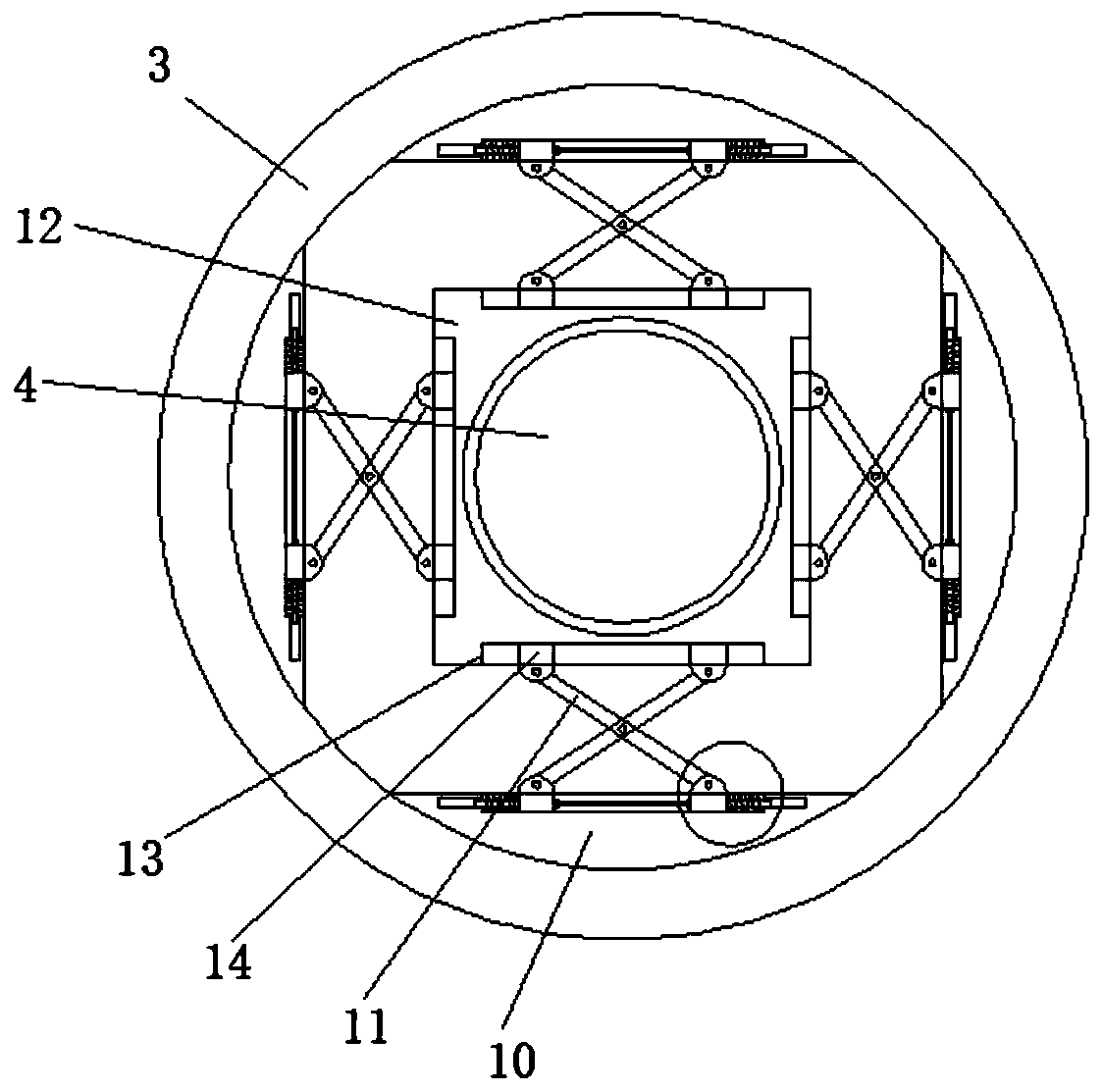

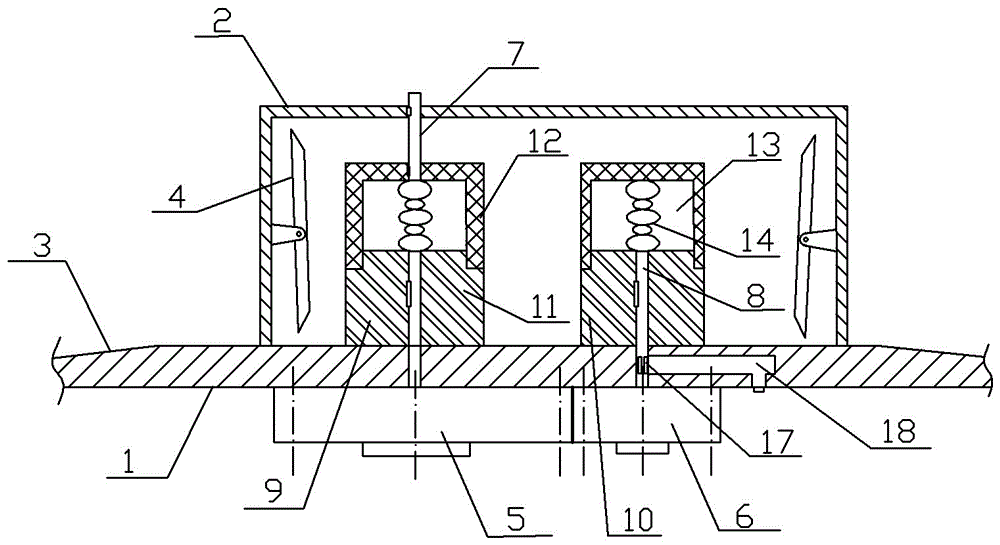

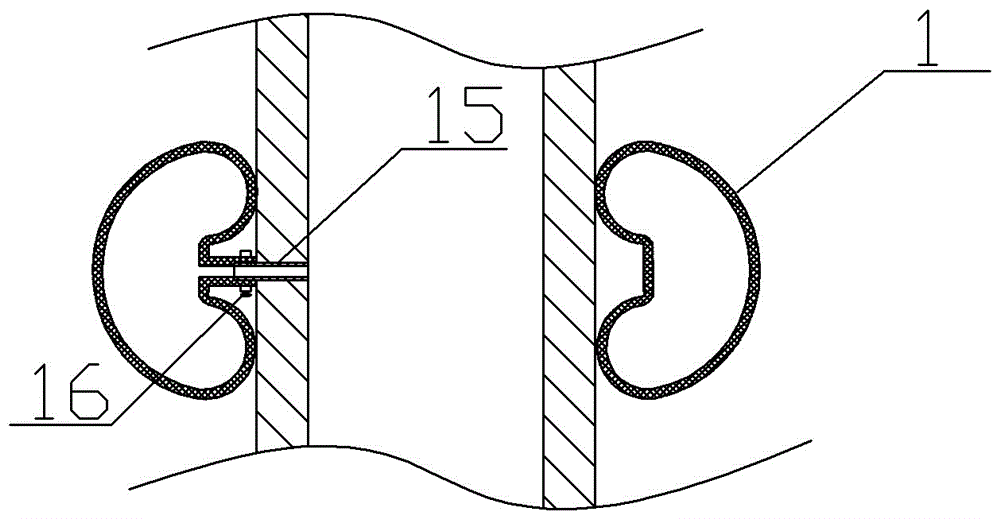

PendingCN108481037ARapid positioningGood meshing effectPositioning apparatusMetal-working holdersSmall footprintEngineering

The invention discloses a gear sleeve machining device and machining method. The gear sleeve machining device comprises a positioning device and a clamp device. The positioning device comprises a base, the top end of the base is fixedly connected with two sets of electric sliding rails arranged in parallel, electric sliding blocks of the electric sliding rails are fixedly connected with sliding rods which are in sliding fit with sliding sleeves, the tops of the sliding rods are fixedly connected with a supporting plate, and a screw rod drive device is fixedly connected to the center position of the supporting plate. The clamp device comprises a machining platform internally provided with two sets of sliding blocks, and the tops of the two sets of sliding blocks are fixedly connected with aleft clamp and a right clamp correspondingly. According to the gear sleeve machining device and machining method, the structure is simple, the occupied space is small, a gear sleeve can be quickly and highly accurately positioned in the vertical direction and the horizontal direction through the electric sliding rails and the screw rod drive device separately, machining errors are reduced, the engagement effect of the sliding gear sleeve and a gear is improved, using is convenient, and operation is simple.

Owner:QUZHOU COLLEGE OF TECH

Curved claw rotor of claw type vacuum pump and molded line design method thereof

PendingCN108678954AIncreased engagement rangeEngagement wire lengthGeometric CADRotary piston pumpsEllipseEngineering

The invention discloses a curved claw rotor of a claw type vacuum pump and a molded line design method thereof. The rotor is composed of nine curved lines: three circular arcs, three elliptic arcs andthree elliptic arc envelope lines. Molded lines are constructed at the top, tip and bottom of the claw of the rotor by adopting the elliptic arcs and the elliptic arc envelope lines. Two rotors engaged to each other are totally same and the molded lines can be correctly engaged; adjacent curved lines are smoothly connected without unsmooth connecting points, so that the mechanical property, the engaging property and the sealing property of the curved claw rotor are improved. The rotor has a smaller clearance volume, the compression power consumption is reduced effectively, and the compressionratio of the claw type vacuum pump is improved. The tip of the claw of the rotor is more flat, large in engaging range and long in engaging line, so that wear is further reduced; the rotor is small in area, and the pumping speed and the volume utilization ratio of the vacuum pump are improved; the types of the molded lines of the claw type rotor are enriched according to the rotor, and the rotoris of important significance to development of the claw type vacuum pump.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Motor shaft for automobile windscreen wipers

ActiveCN108134477AIncrease vibrationAffect normal useMechanical energy handlingSupports/enclosures/casingsFuel tankEngineering

The invention discloses a motor shaft for automobile windscreen wipers, comprising a horizontal motor shaft. One end of the motor shaft is sleeved with a horizontal fixed cylinder. The motor shaft isrotationally connected to the inner wall of the fixed cylinder. The fixed cylinder is provided with a horizontal connecting slot on one side of the top end thereof. A vertical gear plate is arranged above the motor shaft. The motor shaft is provided with an external thread on the side wall of one side near the gear plate. The external thread and the gear plate are meshed with each other. An oil tank is fixed to the inner wall of one side, near the connecting slot, of the bottom end of the fixed cylinder. One outer end of the motor shaft away from the oil tank is sleeved with a shaft sleeve, and the vertical section of the shaft sleeve is square. The vibration of the motor shaft can be buffered, and the motor shaft can be prevented from vibrating drastically to mismatch the gear plate and affect normal use of windscreen wipers. Moreover, the external thread of the motor shaft can be lubricated, in order to improve the meshing effect of the motor shaft and the gear plate and prevent theproblem that the motor shaft and the gear plate cannot rotate normally after passivation.

Owner:宁波创世轴业有限公司

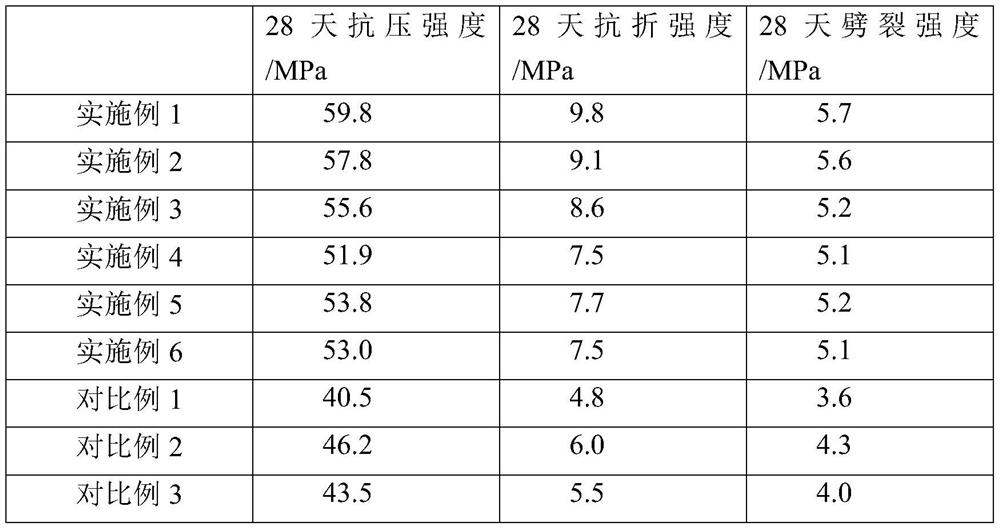

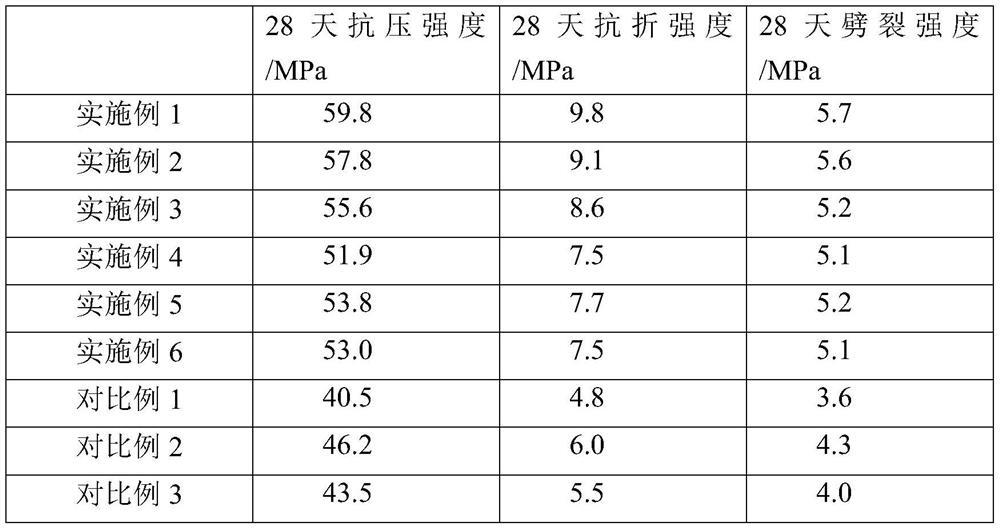

Regenerated glass fiber reinforced plastic-polyvinyl alcohol hybrid fiber high-toughness concrete

ActiveCN114057450AReduce storageIncrease the amount of controlSolid waste managementGlass fiberPolyvinyl alcohol

The invention provides regenerated glass fiber reinforced plastic-polyvinyl alcohol hybrid fiber high-toughness concrete. The concrete is prepared from the following raw materials in parts by weight: 800 to 1000 parts of cement, 30 to 50 parts of silica fume, 1200 to 1350 parts of fine aggregate, 1600 to 2000 parts of coarse aggregate, 10 to 20 parts of large-size regenerated glass fiber reinforced plastic fiber, 20 to 30 parts of medium-size regenerated glass fiber reinforced plastic fiber, 5 to 10 parts of small-size regenerated glass fiber reinforced plastic fiber, 6.3 to 7.5 parts of polyvinyl alcohol fiber, 6.5 to 8.5 parts of water reducing agent, 5.6 to 7.1 parts of defoaming agent, 300 to 400 parts of oxidant solution, 0.2 to 0.5 part of dispersing agent and 400 to 450 parts of water. Toughness is improved by improving binding power of the regenerated glass fiber reinforced plastic fiber in concrete and improving dispersity of the PVA fiber, an oxidizing agent is adopted to conduct surface oxidation treatment on the regenerated glass fiber reinforced plastic fibers, etching is conducted on the fiber surfaces, mechanical meshing is formed on the contact surface of the fibers and the concrete, hydrophilic groups exist in molecular chains of a dispersing agent, when the fibers are soaked in a dispersing agent aqueous solution, wetting of the fibers by water is facilitated, and dispersion is improved. The hybrid fiber concrete prepared by the method is simple in preparation process and convenient to construct, and can be widely applied to the fields of civil engineering, traffic and the like.

Owner:HEBEI UNIV OF TECH +1

Cup-shaped harmonic gear with common tangent double-arc tooth profile and its tooth profile design method

ActiveCN104074948BImprove mechanical propertiesGood meshing effectPortable liftingGearing elementsHarmonicGear tooth

Owner:TIANJIN POLYTECHNIC UNIV

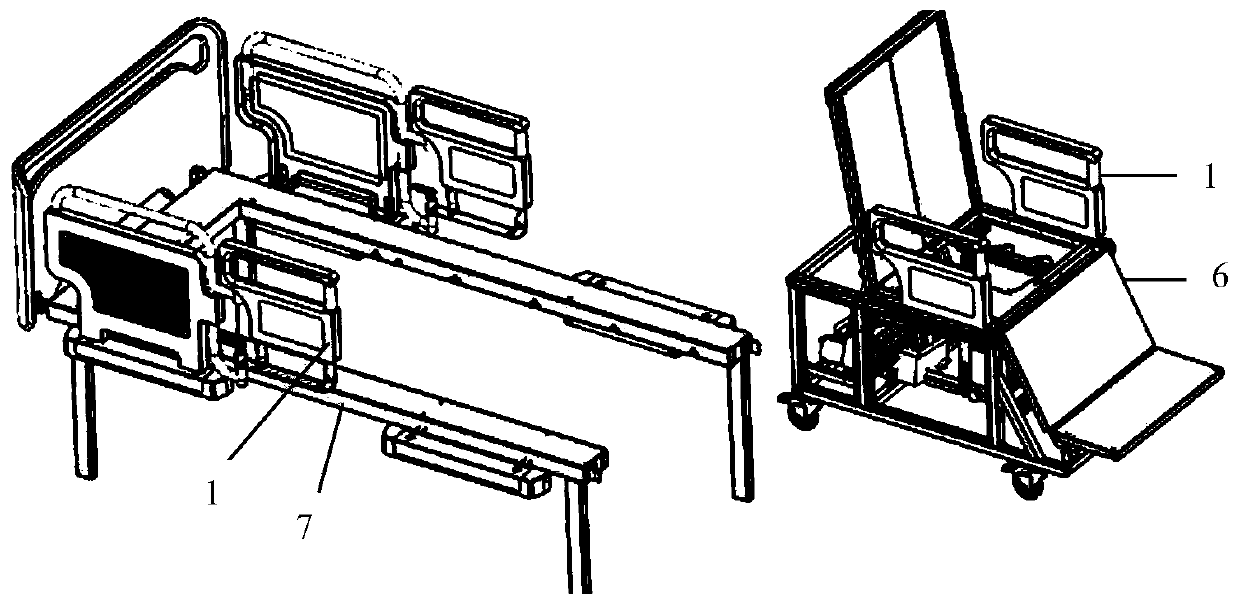

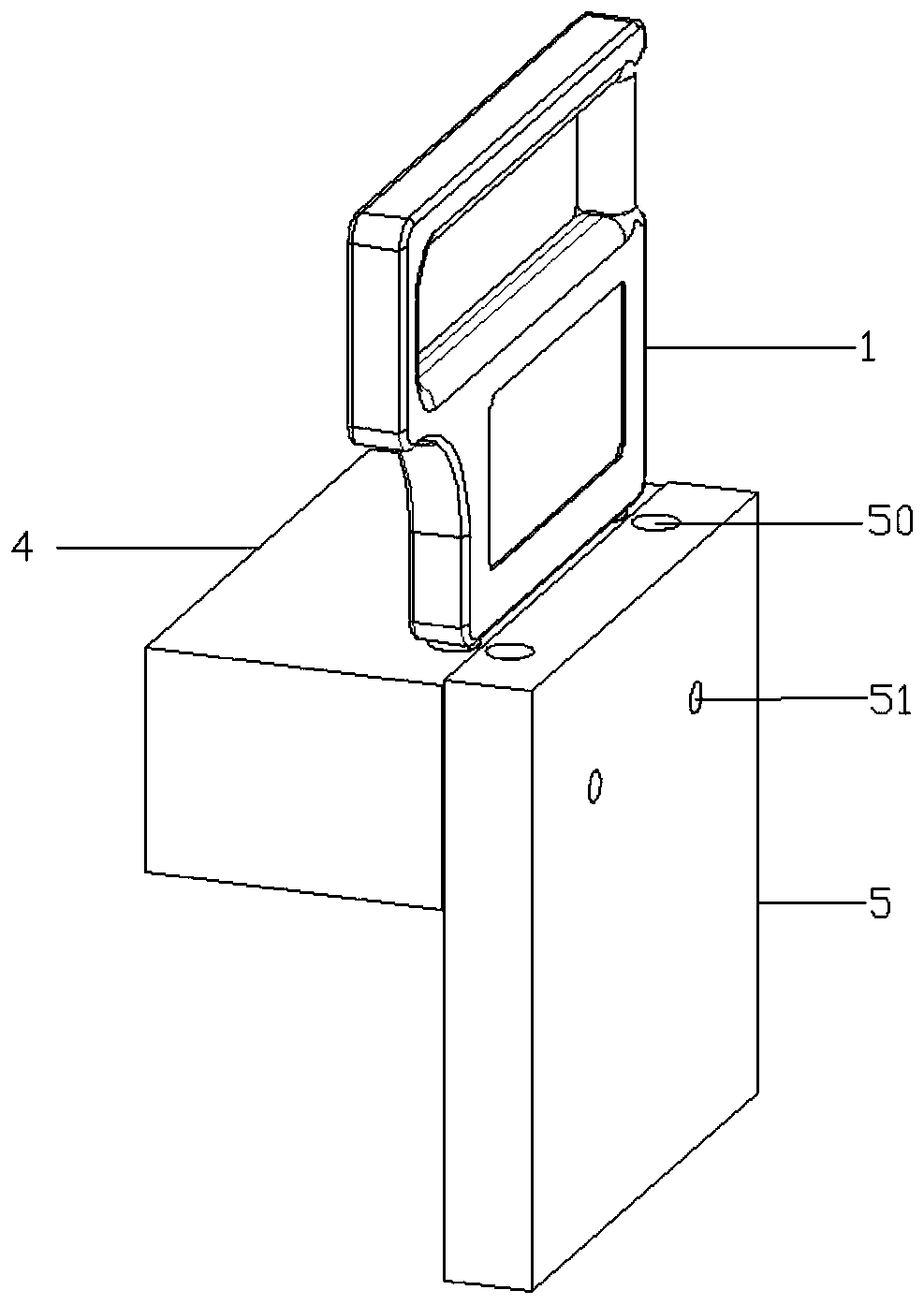

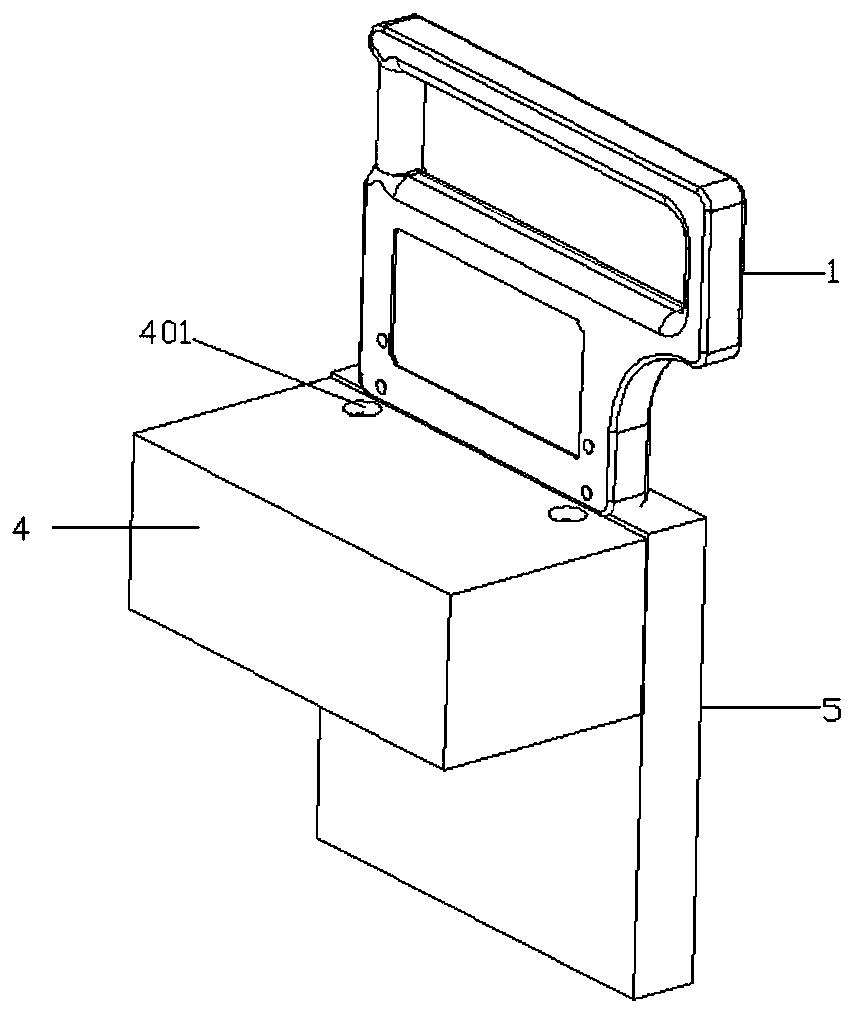

Quick locking and releasing mechanism for wheelchair bed

The invention discloses a quick locking and releasing mechanism for a wheelchair bed. The quick locking and releasing mechanism comprises guardrails, a wheelchair locking assembly fixedly connected tothe wheelchair side of the wheelchair bed and a locking plate fixedly connected to the bed body side of the wheelchair bed. The bottom of the guardrail is connected with a plug pin, the wheelchair locking assembly and the locking plate are provided with a first inserting hole and a second inserting hole respectively, the plug pin can be inserted into the first inserting hole and the second inserting hole respectively, and the guardrail can be detachably connected with the wheelchair locking assembly and the locking plate. The wheelchair locking assembly is used for locking the wheelchair on the bed body. The guardrail disclosed by the invention can be used as a wheelchair-shaped guardrail or a bed-shaped guardrail, so that the storage problem of the guardrail is solved; locking and releasing of the bed body and the wheelchair are achieved while the guardrails are transferred and connected between the bed body and the wheelchair, when the guardrails are connected to the wheelchair, releasing of the wheelchair can be achieved at the same time, when the guardrails are connected to the bed body, wheelchair locking can be achieved at the same time, extra operation is not needed, and convenience and rapidness are achieved.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH CHINESE ACADEMY OF SCI

Bamboo carbon fiber phenolic resin composite material

The invention relates to the technical field of resin materials, in particular to a bamboo carbon fiber phenolic resin composite material. The bamboo carbon fiber phenolic resin composite material isprepared from the following raw materials in parts by weight: 75 to 87 parts of phenolic resin, 40 to 60 parts of polyamide curing agent T31, 15 to 25 parts of modified bamboo carbon fibers, 2 to 10 parts of hydroxymethyl cellulose, 1 to 7 parts of N-methyl acetamide, 1.5 to 3 parts of AC foaming agent, 3 to 9 parts of PVC foaming regulator, 1 to 2.5 parts of brominated polyethylene, 0.3 to 1.6 parts of stearic acid, 0.4 to 3.5 parts of talcum powder, and 1.2 to 3 parts of potassium hexatitanate whisker. The bamboo carbon fiber phenolic resin composite material is excellent in mechanical performance.

Owner:安徽省科晟生态木装饰材料有限公司

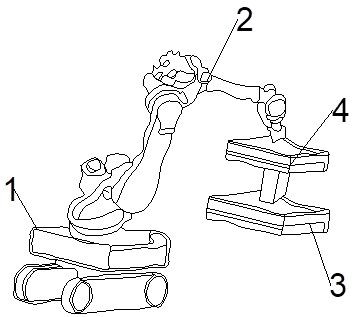

Anti-collision protection type suction cup for excavator based on 5G technology

PendingCN112627275AImprove work efficiencyImprove mobile stabilitySoil-shifting machines/dredgersRoad cleaningRemote controlControl engineering

The invention discloses an anti-collision protection type suction cup for an excavator based on the 5G technology. An excavator body is included, the excavator body is connected with an excavator arm, the movable end of the excavator arm is connected with a buffer assembly, and the buffer assembly is connected with the suction cup. According to the anti-collision protection type suction cup, a carrier controller is arranged on the excavator body, data transmission between the carrier controller and a 5G data transmission module is achieved through an API, data transmission between the 5G data transmission module and a networking module is achieved through an API, the networking module is connected with a remote control terminal, and the remote control terminal is used for remote control over the excavator body 1, so that remote operation work is achieved through the 5G technology, and the work efficiency is improved.

Owner:海江科技集团有限公司 +3

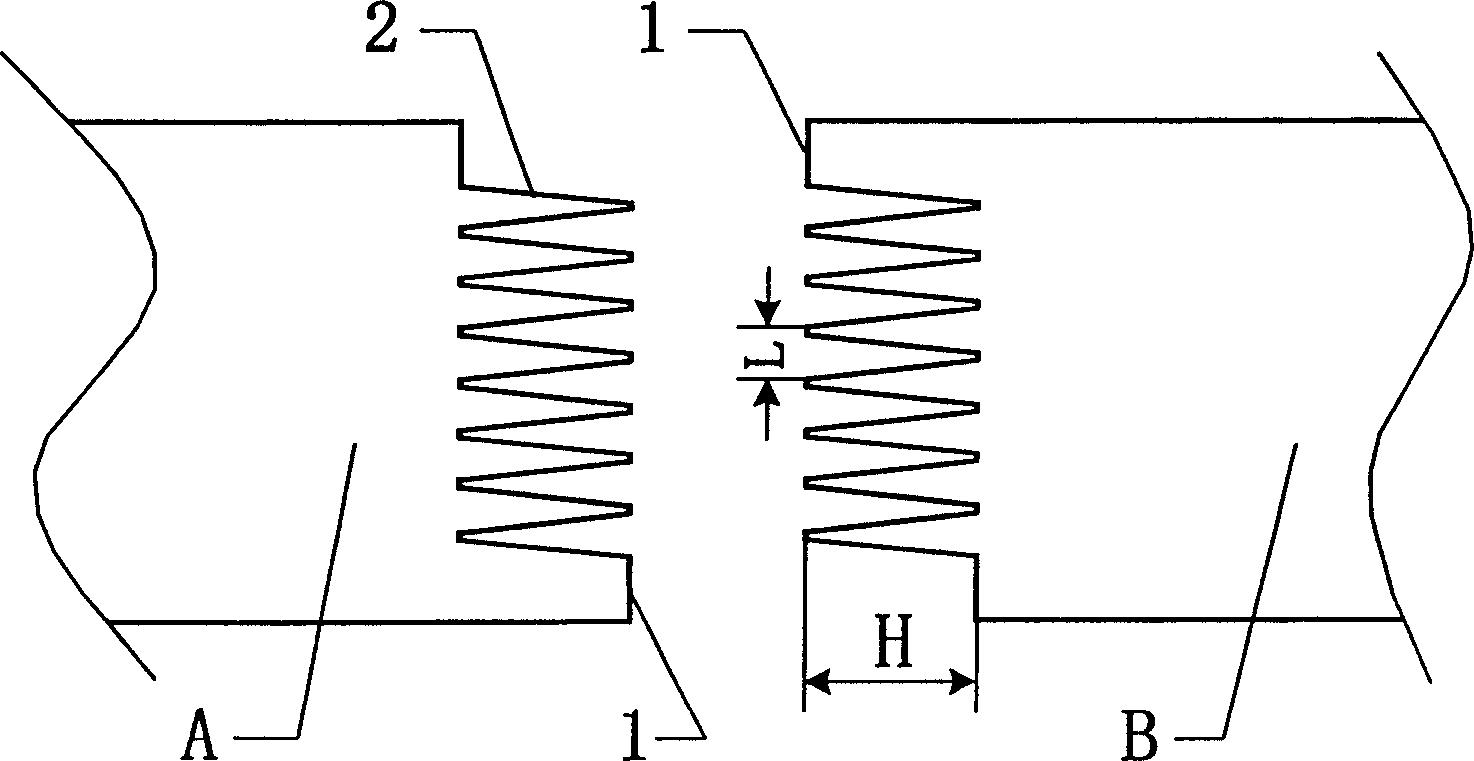

Dimension lumber tooth-connecting elongating method

InactiveCN1891419ACompressive strength no less thanNot easy to damageDrying solid materials with heatDrying solid materials without heatEngineeringCompressive strength

Owner:TECSUN SUZHOU HOME

Harmonic gear with continuous meshing tooth profile and tooth profile design method thereof

ActiveCN111810608AHigh transmission precisionGood meshing effectGeometric CADGearingGear wheelEngineering

The invention provides a harmonic gear with a continuous meshing tooth profile, and provides a tooth profile design method of the harmonic gear with the continuous meshing tooth profile formed by applying a rotation transformation method. The harmonic gear consists of a rigid wheel, a flexible wheel and a wave generator, wherein the rigid wheel is a rigid inner gear; the flexible wheel is a cup-shaped cylindrical straight-tooth outer gear; the difference between the number of teeth of the rigid wheel and the number of teeth of the flexible wheel is two; the tooth profile of the rigid wheel isgenerated by shifting and equidistant of a movement track of points on a center line of the deformation end of the flexible wheel described by the rotation transformation method; and the tooth profileof the flexible gear consists of an arc tooth top with the equidistant distance as the radius of the designed rigid wheel tooth profile and a curve with smooth transition with the arc tooth top. Thedesign method has the characteristics that the tooth profile design is simple and convenient, the designed harmonic gear has the advantages of many meshing teeth, high bearing capacity, long fatigue life, small distortion of the flexible wheel, large meshing depth, high transmission precision, good stability and wear resistance, and the design method is very suitable for tooth profile design of harmonic gear transmission.

Owner:金齿传动科技(大连)有限公司

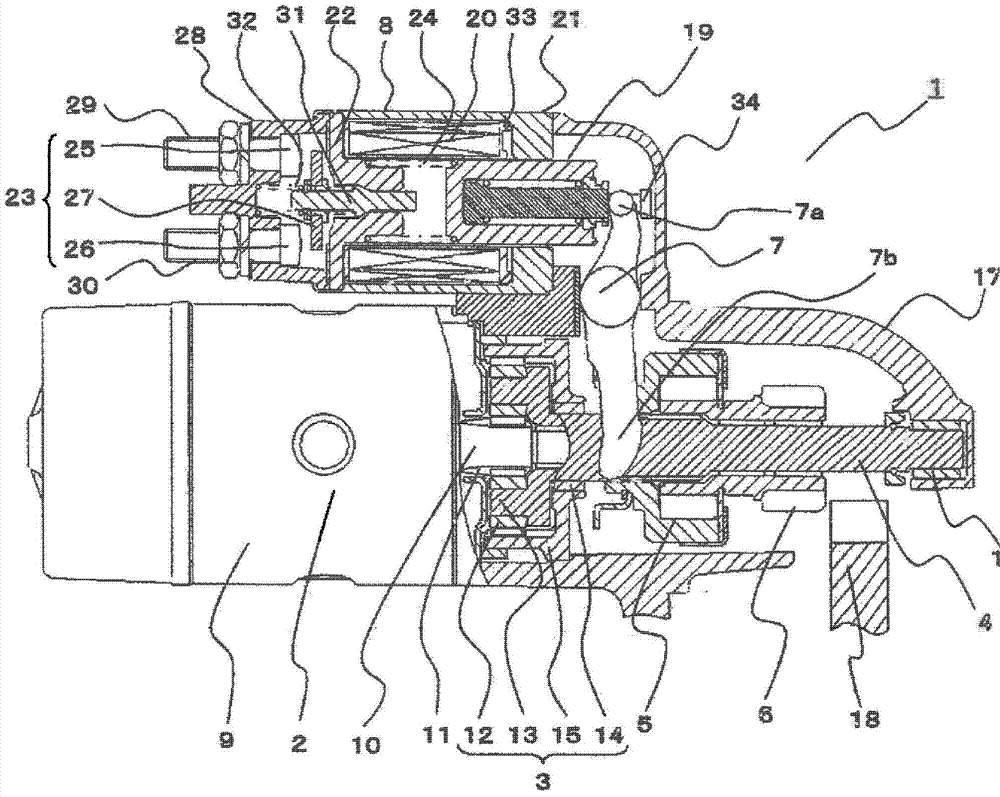

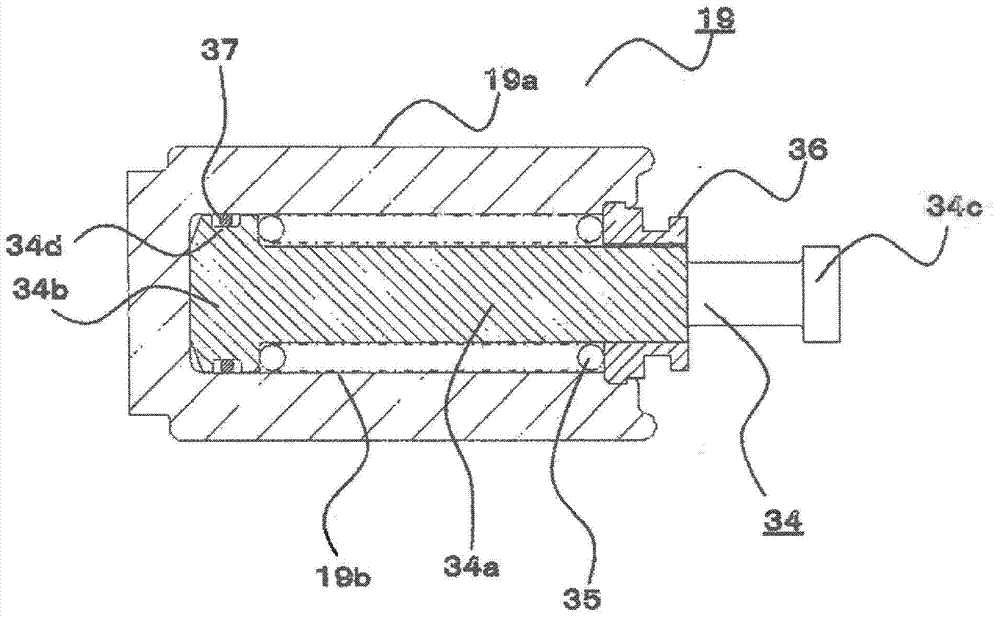

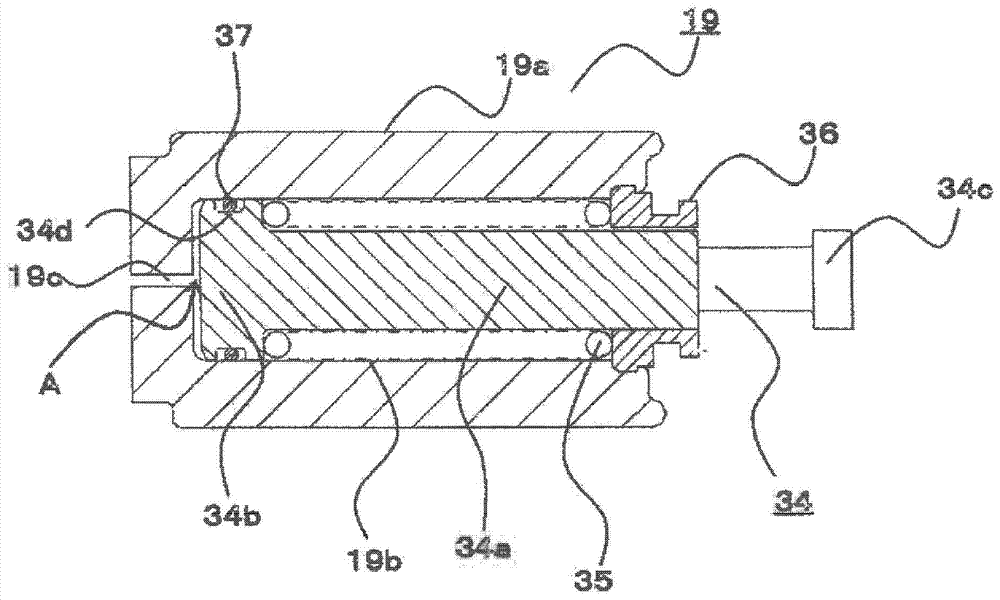

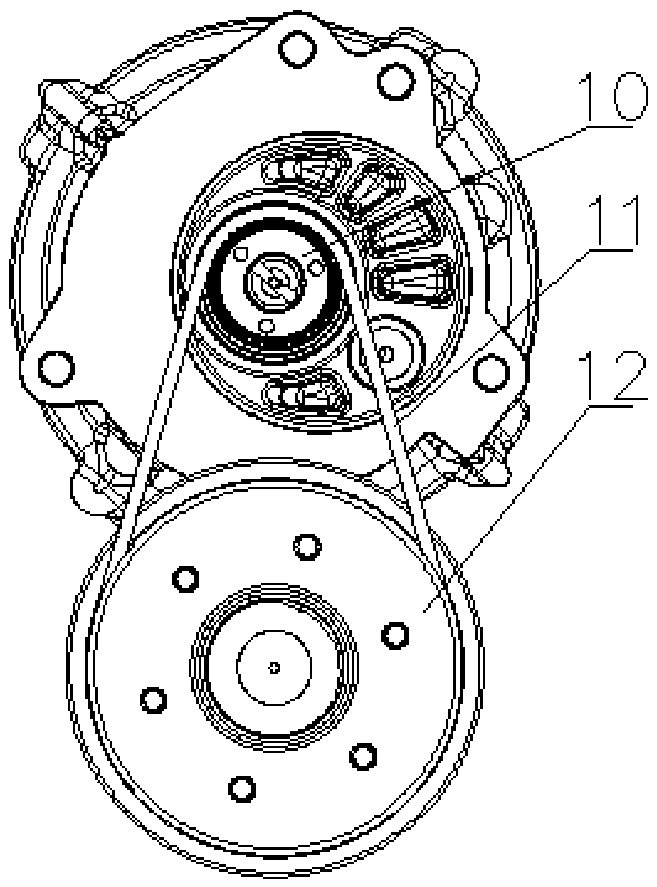

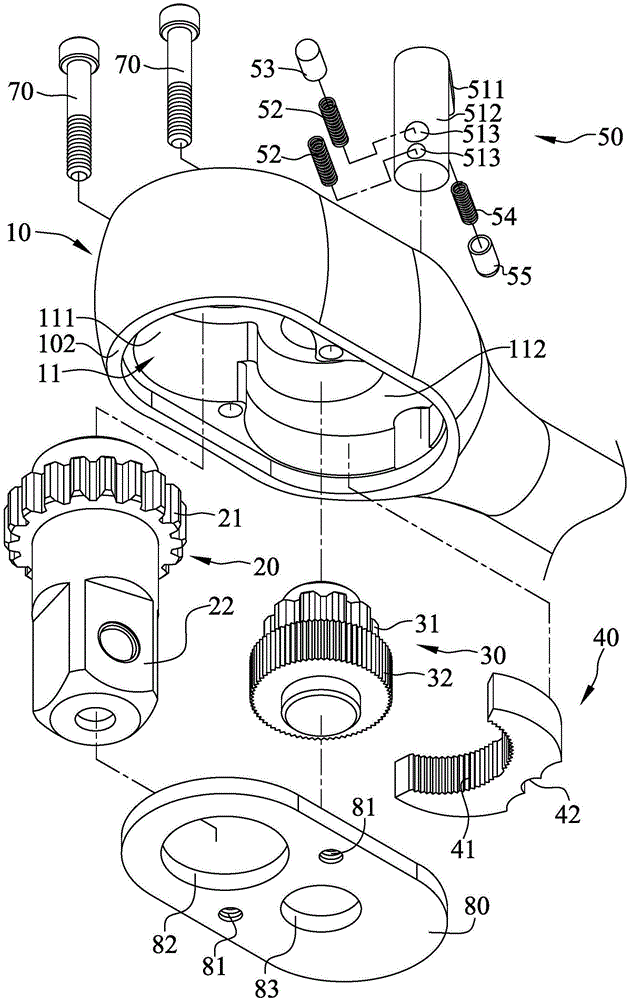

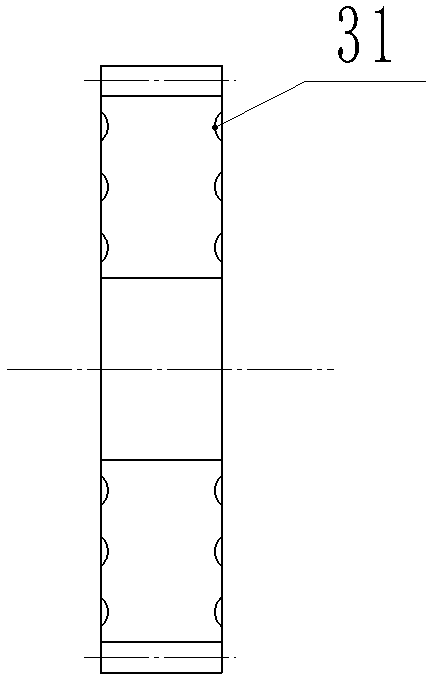

Starter

InactiveCN103775264AInhibit sheddingAvoid deflectionPower operated startersElectric motor startersEngineeringStart up

A starter is disposed with an elastic body which generates slide resistance between the inner circumferential surface of a cylinder hole of a movable core and a first annular groove section of a flange section of a hook and the starter has an air damper function; and consequently, the effect of suppressing compression of a drive spring can be sufficiently obtained without reducing the suction speed of a plunger as much as possible and an engine can be rapidly started up.

Owner:MITSUBISHI ELECTRIC CORP

A Modification Method of Involute Tooth Profile in Harmonic Drive

ActiveCN107882950BIncrease the number of teethSmall engagement backlashGearingPortable liftingKinematic theoryGear wheel

The invention discloses a modification method for a harmonic driving involute profile. A point B serves as a point of tangency of a modification curve and a involute tooth surface. A point E serves asa point of intersection of the modification curve and an involute addendum circle. A coordinate system XOY is built with a radial OA as the abscissa axis. A coordinate system X1OY1 is built with a radial OC as the ordinate axis. After the steps of determining the coordinates of the point B and the point E in the coordinate system X1OY1 and the slope of a tangent of the involute at the point B, determining a flexible gear central point approximate movement track curvilinear equation, determining the parameter equation of the modification curve in the coordinate system X1OY1 and the like, a system of simultaneous equations is built and used for solving parameters, and the parameter equation of the modification curve in the coordinate system XOY is obtained through conversion of the coordinate system. According to the modification method, the harmonic driving involute profile is modified based on the harmonic driving kinematics theory, processing manufacturability and economy can be guaranteed, engagement performance is improved, the advantages of various harmonic tooth profiles are integrated, and the modification method can be widely applied to the technical field of harmonic gears.

Owner:国茂精密传动(常州)有限公司

A kind of recycled fiberglass-polyvinyl alcohol hybrid fiber high-toughness concrete

ActiveCN114057450BReduce storageIncrease the amount of controlSolid waste managementPolyvinyl alcoholArchitectural engineering

The invention provides a recycled fiberglass-polyvinyl alcohol hybrid fiber high-toughness concrete. The weight fractions of raw materials are: cement 800-1000 parts, silica fume 30-50 parts, fine aggregate 1200-1350 parts, coarse aggregate 1600-2000 parts, recycled fiberglass large size 10-20 parts, medium size 20-30 parts parts, small size 5-10 parts, polyvinyl alcohol fiber 6.3-7.5 parts, water reducing agent 6.5-8.5 parts, defoamer 5.6-7.1 parts, oxidant solution 300-400 parts, dispersant 0.2-0.5 parts, water 400 parts ‑450 copies. The toughness is improved by improving the adhesion of recycled fiberglass in concrete and improving the dispersibility of PVA fiber. The surface of recycled fiberglass is oxidized by oxidizing agent, and the fiber surface is etched, forming mechanical meshing with the concrete contact surface, dispersing There are hydrophilic groups in the molecular chain of the agent. When the fiber is soaked in the aqueous solution of the dispersant, it will help the water to wet the fiber and improve the dispersion. The hybrid fiber concrete prepared by the invention has a simple preparation process, is convenient for construction, and can be widely used in the fields of civil engineering, transportation and the like.

Owner:HEBEI UNIV OF TECH +1

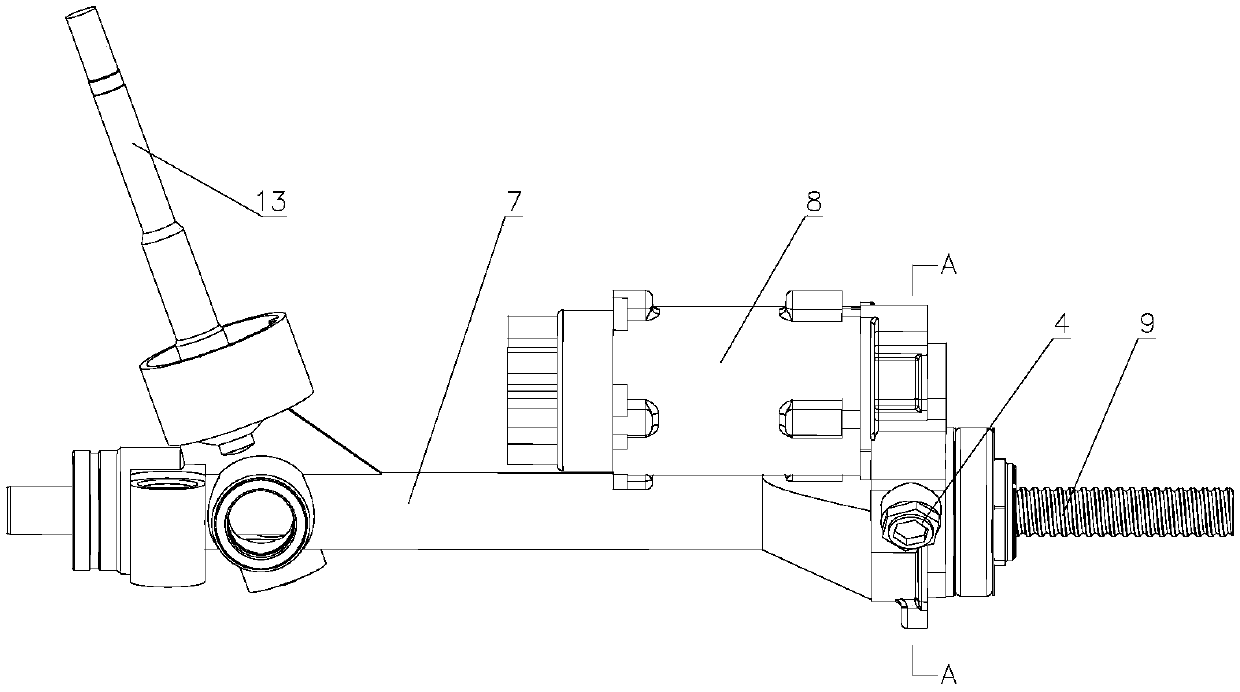

Backlash-compensation intelligent electric power steering gear and working method

PendingCN110733559AAvoid noiseGood meshing effectElectrical steeringElectric power steeringGear wheel

The invention discloses a backlash-compensation intelligent electric power steering gear, which comprises a shell, a motor, a steering shaft, a motor end gear, an idle wheel, a lead screw nut end gearand a lead screw, wherein the steering shaft is connected to the left side of the shell; the motor is fixed on the right side of the shell; the motor end gear is installed on the output shaft of themotor; the lead screw is positioned on the inner side of the shell, and the outer circumference of the right side output end of the lead screw is fixedly provided with the lead screw nut end gear; theidler wheel is meshed and connected between the motor end gear and the lead screw nut end gear in the shell; the side end of the shell is also fixedly provided with a pressure block plug; a pressureblock which is in mutual contact and spaces the radial movement of the idler wheel is arranged in the pressure block plug; and a spiral spring is also placed on the inner side of the pressure block plug and between the pressure block plug and the pressure block. Since the electric power steering gear disclosed by the invention adopts a backlash-compensation structure, the problems that abrasion islikely to generate, a belt is loosened and service life is limited can be solved.

Owner:ZHEJIANG SHIBAO CO LTD

A dispensing device for power maintenance tools that manually selects and changes elastic elements, voltage regulators and stabilizers

ActiveCN108963852BBalance weightPrevent shake offCable installation apparatusMetal-working hand toolsElastic componentGear wheel

Owner:黄冈东源电业集团有限公司

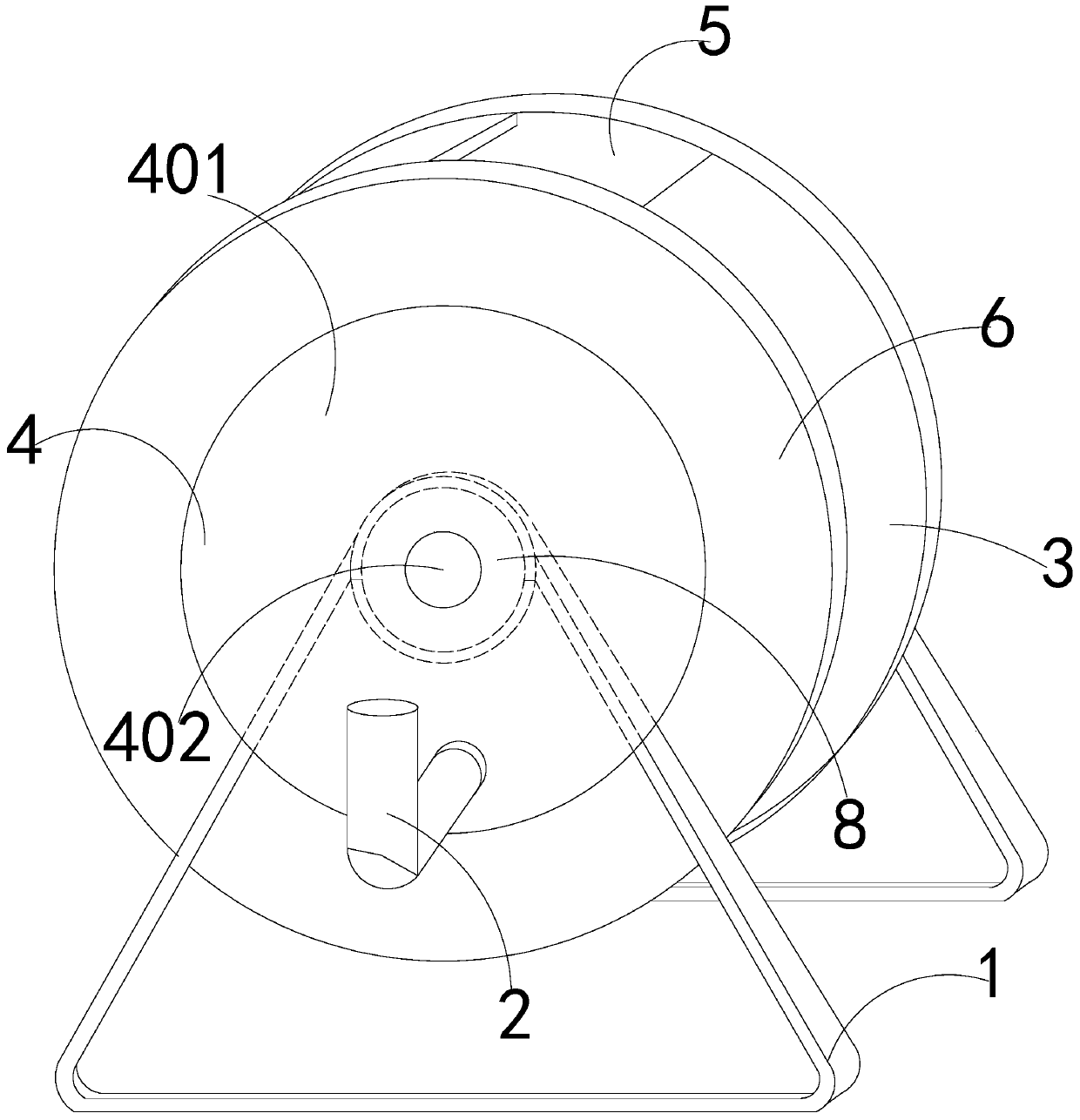

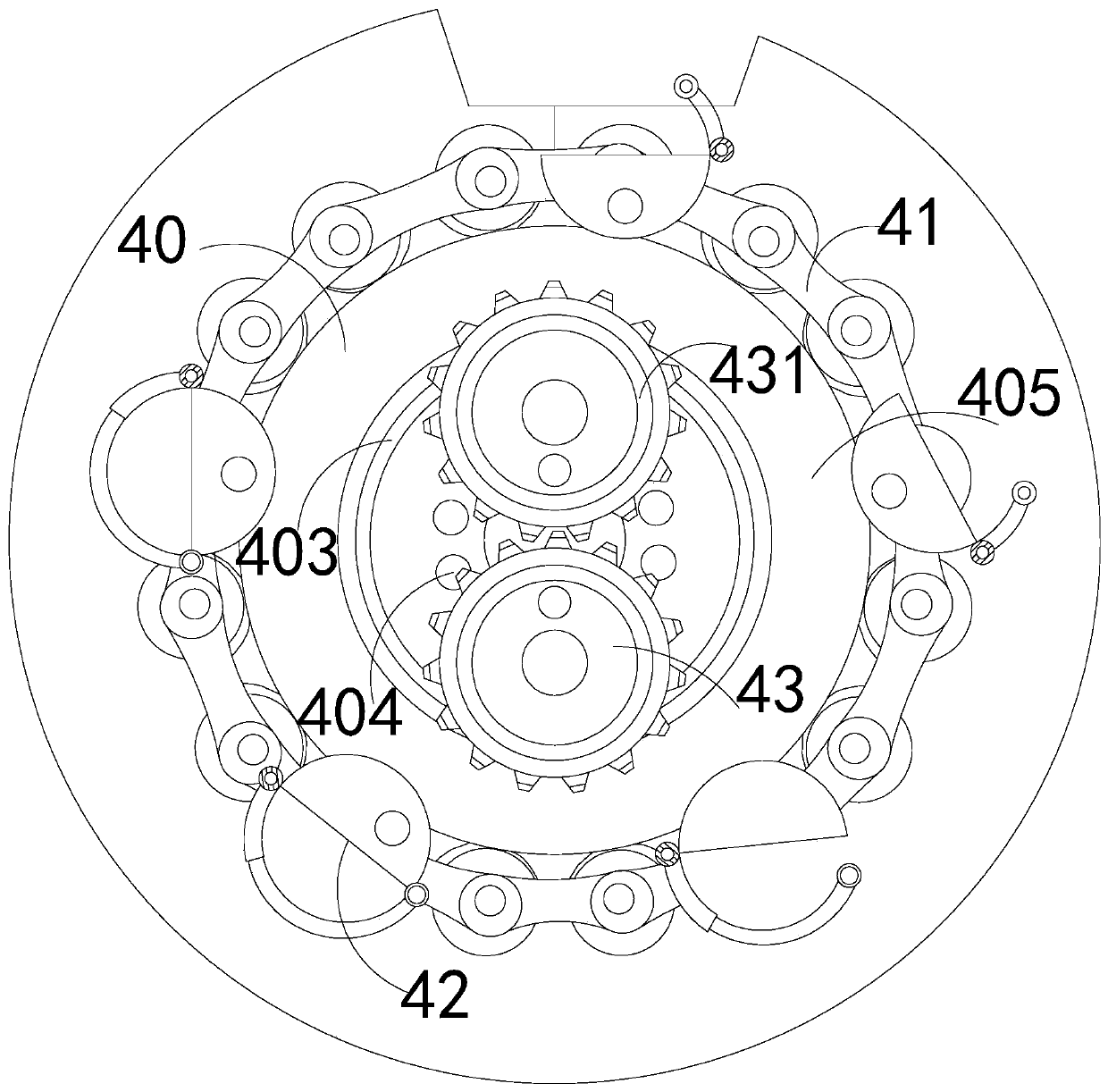

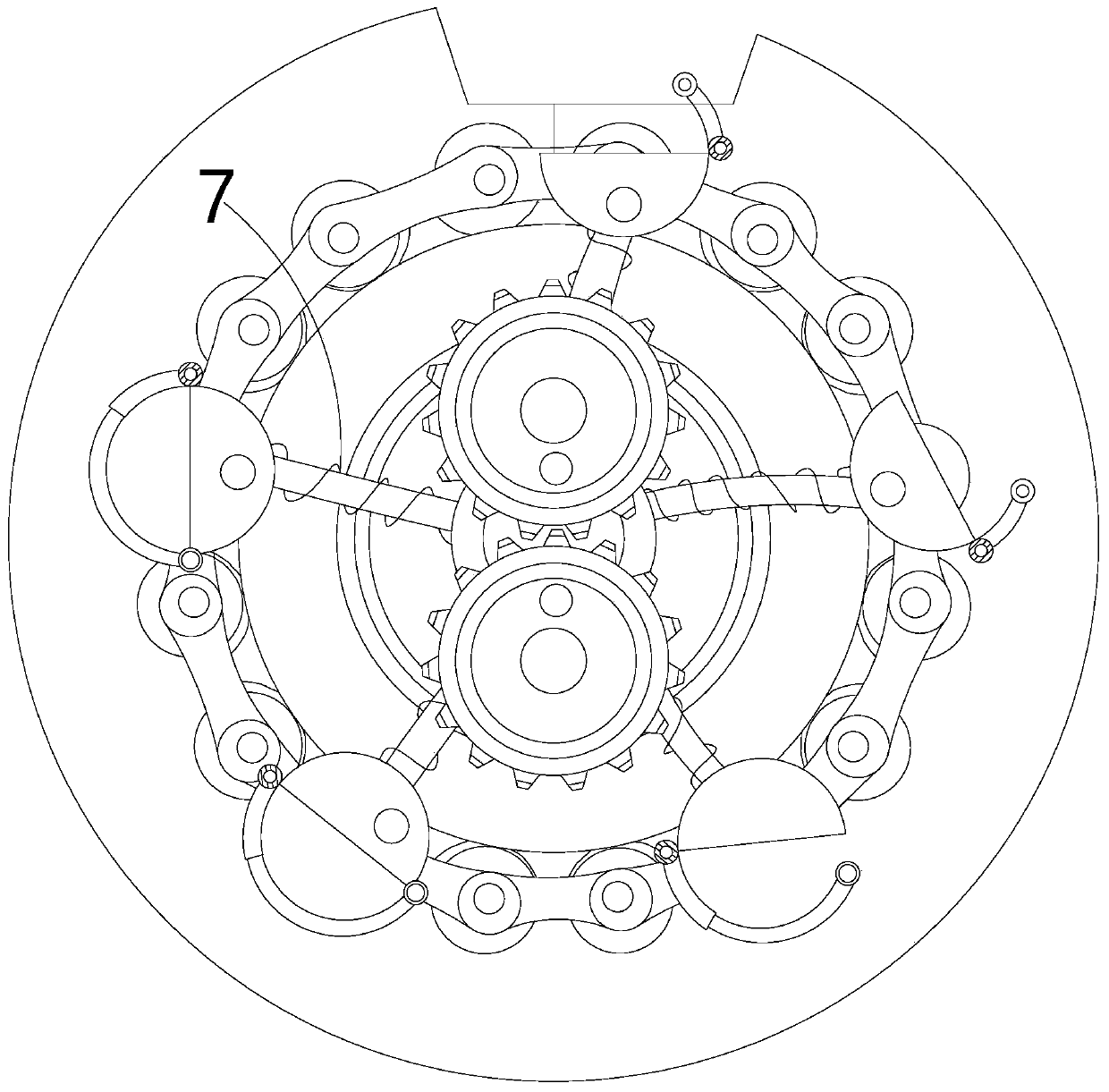

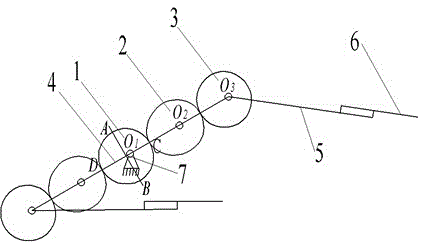

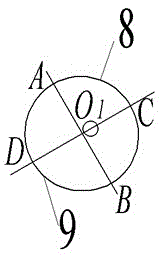

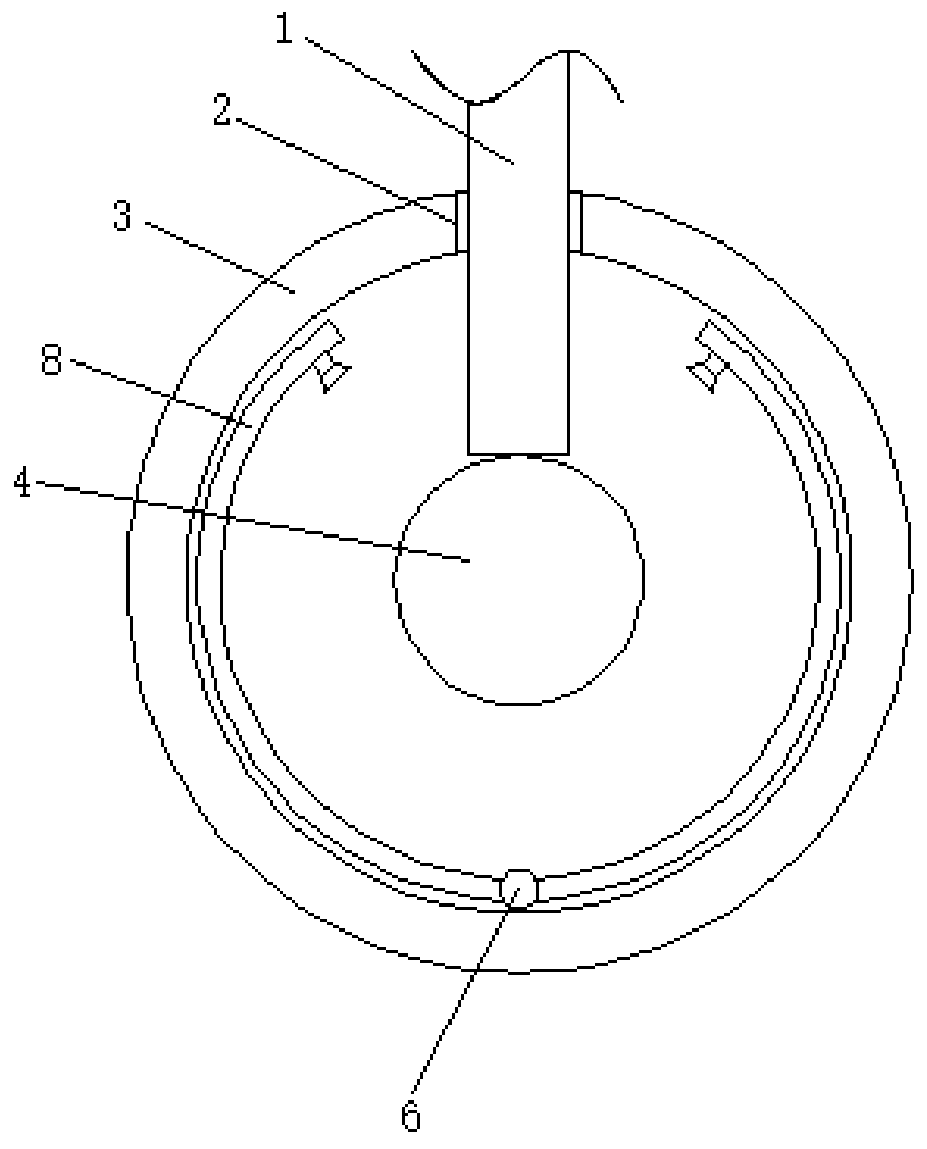

Rotary Box of Circular-Elliptical Pitch Curve Gear Planetary System

The invention discloses a circular-elliptic knot curve gear planetary system rotating box of a transplanting mechanism. The circular-oval knot curve gear planetary system rotating box mainly comprises a sun gear, two middle wheels, two planet wheels, a planet carrier, two planting arms, two seedling needles and a stand. Due to the transmission ratio of a transmission gear of the transplanting mechanism, the transplanting mechanism is less in seedling damage during transplanting; the knot curve of the sun gear is formed by a section of elliptic arc curve ACB and a section of circular arc curve ADB which are in smooth connection with each other; the transplanting mechanism is small in vibration and free from the phenomena of seedling floating and seedling laying.

Owner:ZHEJIANG SCI-TECH UNIV

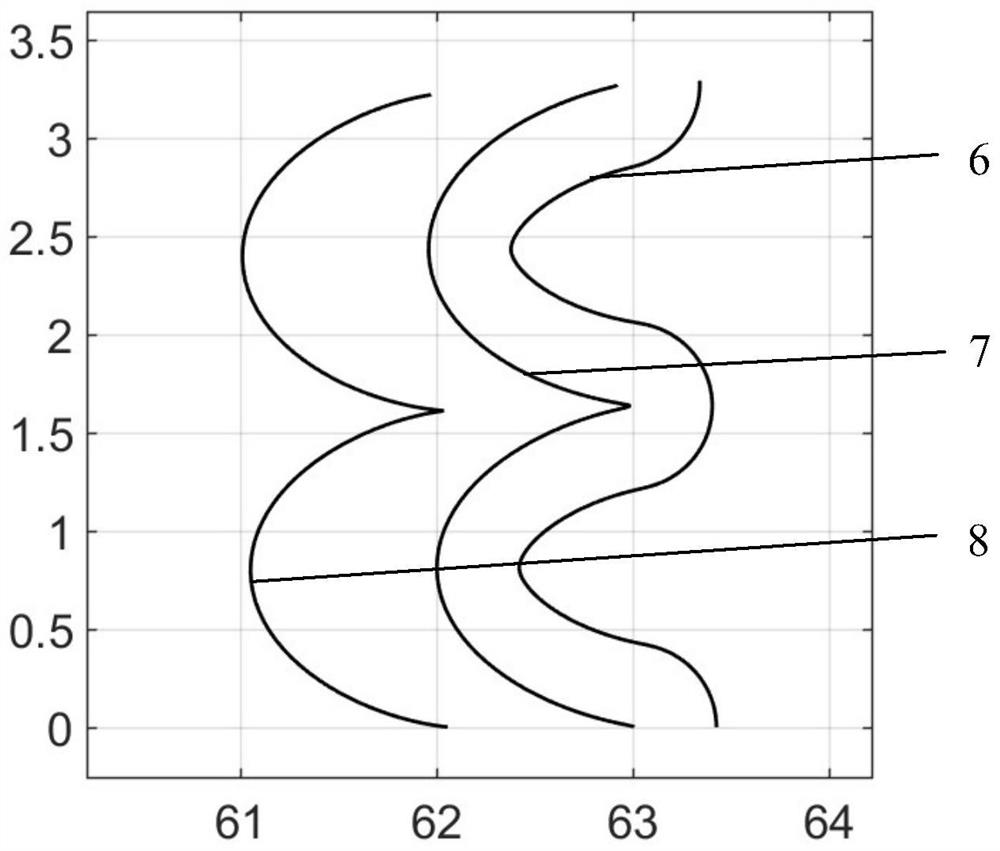

Method for improving meshing performance of ultra-short cup-shaped harmonic flexible gear through axial modification

The invention discloses a method for improving meshing performance of an ultra-short cup-shaped harmonic flexible gear through axial modification. According to the method, axial modification is performed on two ends of gear teeth of the ultra-short cup-shaped harmonic flexible gear, and modification is not performed in a middle tooth width range near the middle section of the gear teeth. The gearteeth of the modified gear are divided into three sections within the full tooth width range, and the form that the middle is high and the two ends are low is shown. After axial modification, pitch circle lines of the front and rear sections of gear teeth and the rotation central axis of the harmonic flexible gear form a first contact angle and a second contact angle respectively, and the first contact angle and the second contact angle are the same as deformation inclination angles generated at the two ends of a long shaft of a cam by the flexible gear after a wave generator is installed on the ultra-short cup-shaped harmonic flexible gear respectively. The deformation inclination angles generated at the two ends of the long shaft of the cam by the flexible gear after the wave generator is arranged in the ultra-short cup-shaped harmonic flexible gear are offset, so that the gear teeth of the flexible gear and gear teeth of a rigid gear can be kept in a good meshing state in all axialsections, and the meshing performance of the ultra-short cup-shaped harmonic flexible gear is improved.

Owner:GUIZHOU QUNJIAN PRECISION MACHINERY

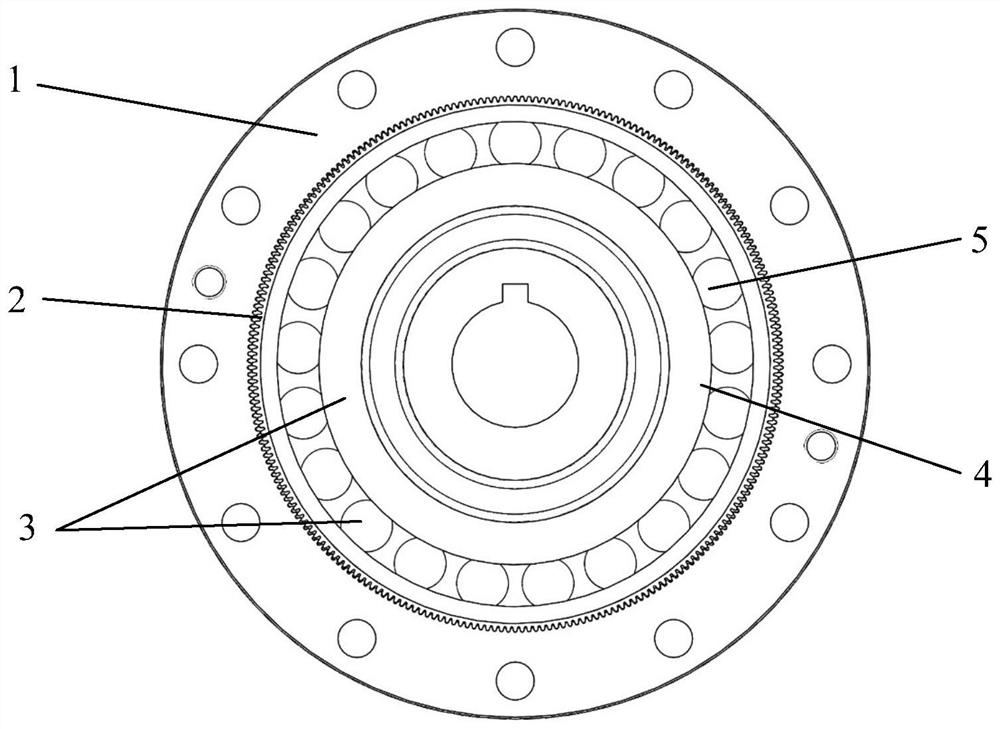

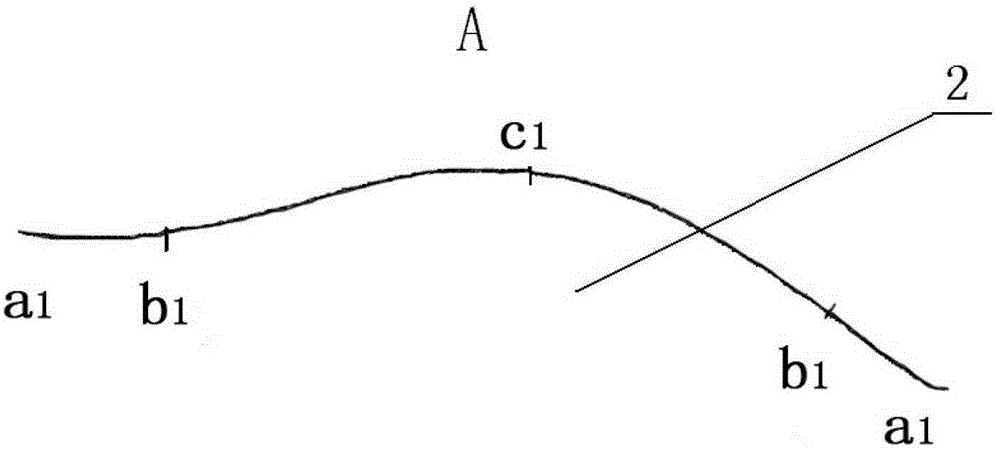

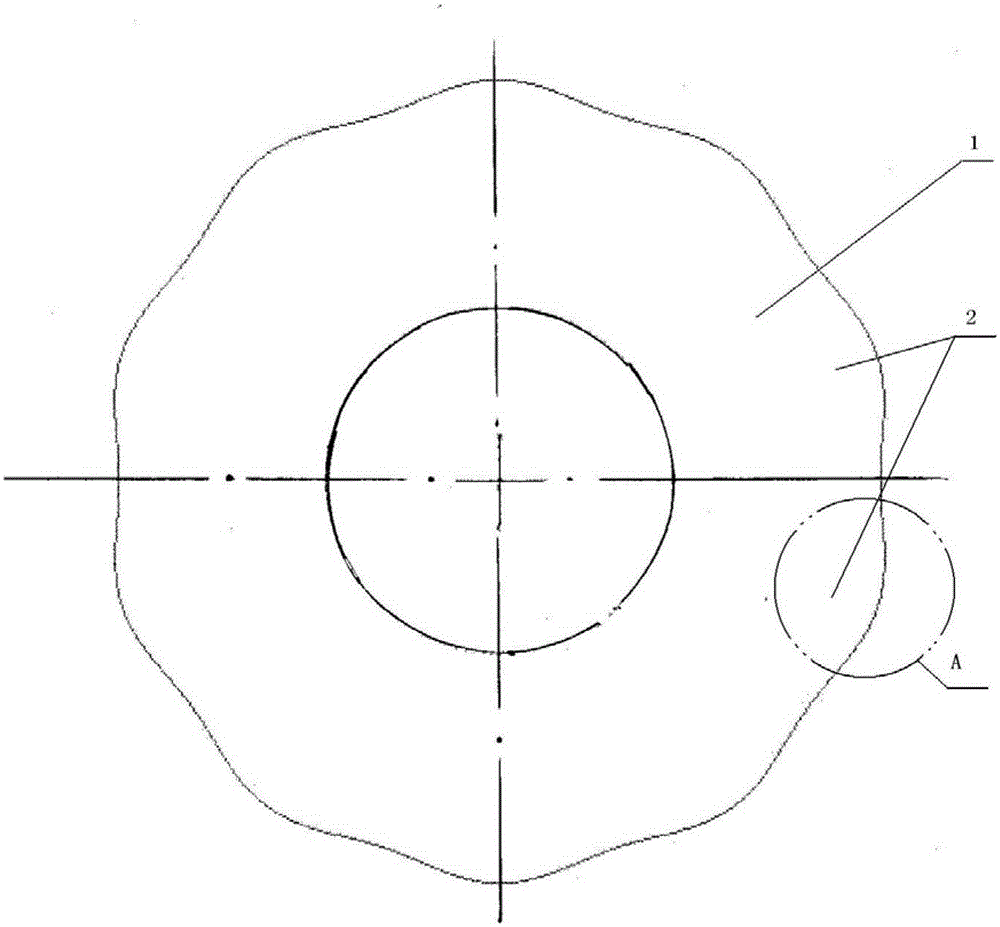

The Design Method of the Center Wheel Tooth Shape of the Nutating Movable Gear Transmission Mechanism

ActiveCN103195908BImprove machinabilityReduce rolling noisePortable liftingSpecial data processing applicationsNutationEngineering

The invention belongs to nutation movable tooth transmission devices, particularly relates to a central gear tooth shape of a nutation movable tooth transmission mechanism and a design method of the central gear tooth shape. The central gear tooth shape comprises a central gear and is characterized in that the tooth shape of the central gear (1) is a spherical arc curve, the tooth shape of each single tooth (2) is formed by two symmetric hemispherical circular curves, each semispherical circular curve is formed by an arc curve a1b1 between a tooth root point a1 and a tangent point b1 and a circular curve between a tangent point b1 and a tooth vertex b1, and a joint of each two circular curves forms the spherical arc curve tooth shape integrally smooth through smooth transition. The central gear tooth shape of the nutation movable tooth transmission mechanism is reasonable in design, simple and practical, convenient to process, low in noise and the like, and root cutting is reduced while meshing performance is improved.

Owner:DALIAN JIAOTONG UNIVERSITY

A plastic kneader

ActiveCN106738413BImprove kneading effectAvoid problems with stuck in the mixing chamberAir pumpEngineering

The invention belongs to the technical field of packaging, and discloses a plastic kneader. The plastic kneader comprises a fixed base; a top cover is arranged on the fixed base; a press plate is hinged to the side wall of the top cover; a driving transmission cylinder is vertically arranged on the fixed base and penetrates through the top cover; the driving transmission cylinder is in flat key connection with the eccentric position of the top cover; an air pump is externally connected with the upper end of the driving transmission cylinder; a penetrating hole is formed in the fixed base; an air flue communicating with the penetrating hole is arranged inside the fixed base and externally connected with the air pump; a driven transmission cylinder is inserted into the penetrating hole; the cylinder body section, on an inner cavity of the top cover, of the driving transmission cylinder is in flat key connection with a driving stirring piece; the upper end of the driven transmission cylinder extends into the inner cavity of the top cover but is not connected with the top cover; and the section, extending into the top cover, of the driven transmission cylinder is connected with a driven stirring piece. The plastic kneader can engage materials at the dead corners and improve the overall kneading effect of the materials.

Owner:CHONGQING RUITING PLASTIC

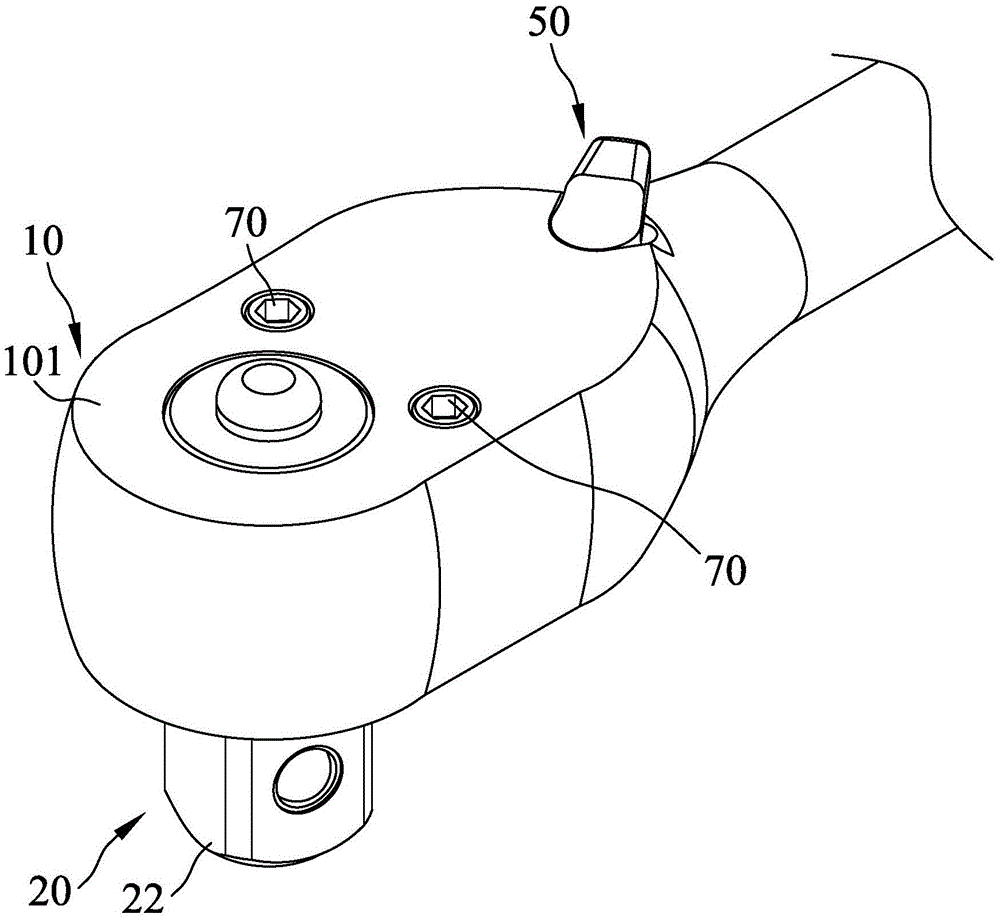

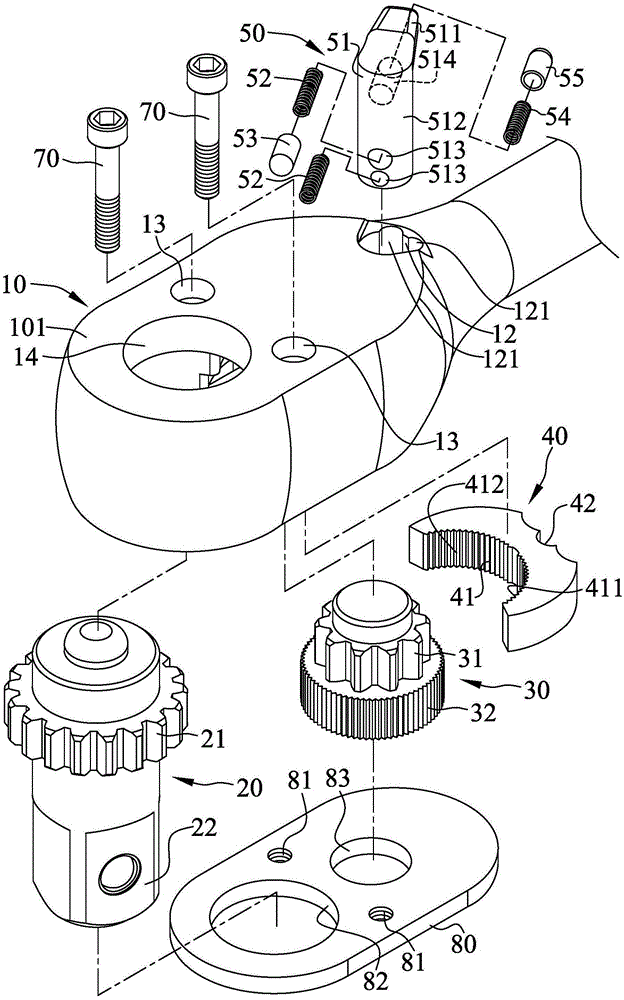

ratchet wrench

The invention relates to a ratchet wrench comprising a body, a drive head, a ratchet wheel, at least one ratchet block and a reversing device. The body is provided with a chamber including a first section and a second section. The drive head is rotatably provided at the first section; two opposite ends of the drive head are provided with a first toothed portion and a dive portion; the first toothed portion surrounds the outer periphery of the drive head; the drive portion can drive a member to be driven. The ratchet wheel is rotatably disposed at the second section of the chamber and comprises a second toothed portion and a third toothed portion; the second toothed portion and the second toothed portion surround the two opposite ends of the outer periphery of the ratchet wheel, respectively; the second toothed portion meshes with the first toothed portion of the drive head; the toothed blocks are slidably disposed at the second section of the chamber; each ratchet block comprises a fourth toothed portion which is arranged on one end face, close to the ratchet wheel, of the ratchet block; each fourth toothed portion selectively meshes with the third toothed portion of the ratchet wheel; the reversing device is pivoted to the body and abutted to the ratchet blocks.

Owner:NEW WAY TOOLS

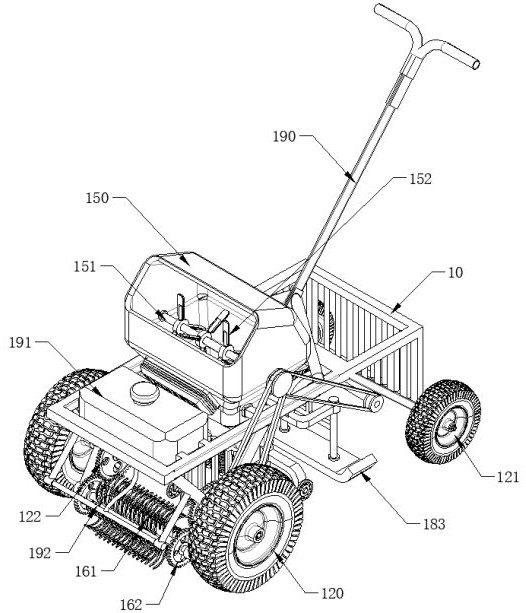

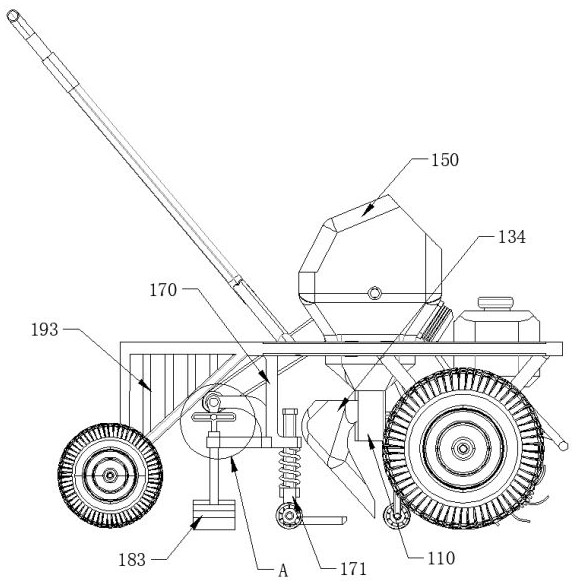

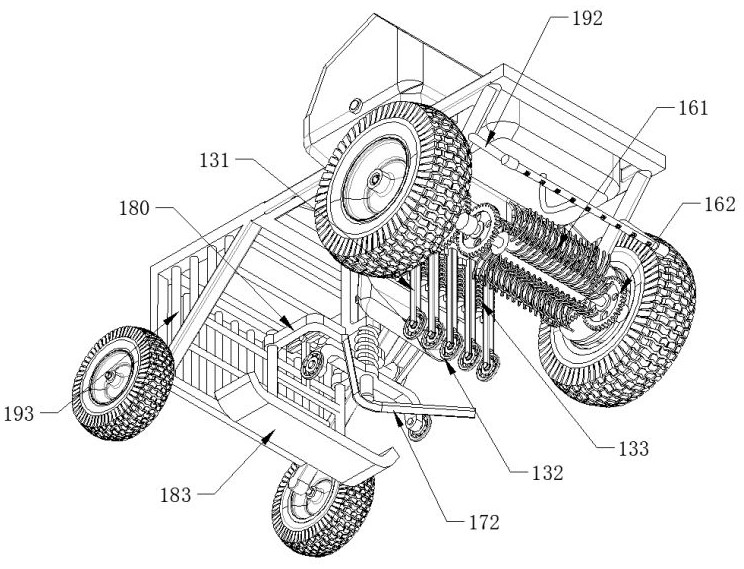

Crack repairing device for road and bridge repairing

PendingCN114753226AAvoid accumulation on the roadReduce construction costsUsing liquid separation agentBridge erection/assemblyArchitectural engineeringEngineering

The invention provides a crack repairing device for road and bridge repairing, which comprises a vehicle body, and further comprises a stirring component fixedly connected to the top wall of the vehicle body, and a discharging component, the discharging assembly comprises a discharging pipe fixedly connected to a discharging opening of the stirring component, a material distributing plate fixedly connected to the inner wall of the discharging pipe, a quantitative material guiding component slidably connected to the inner wall of the discharging pipe, a cleaning component, a ramming assembly fixedly connected to the top wall of the vehicle body and a discharging component fixedly connected to the top wall of the vehicle body. The input end of the tamping assembly is connected with the stirring component through a belt and a belt wheel. The purpose of quantitative discharging according to the crack depth can be achieved, the situation that materials are accumulated on the road surface is avoided, and the construction cost is reduced.

Owner:卫杰

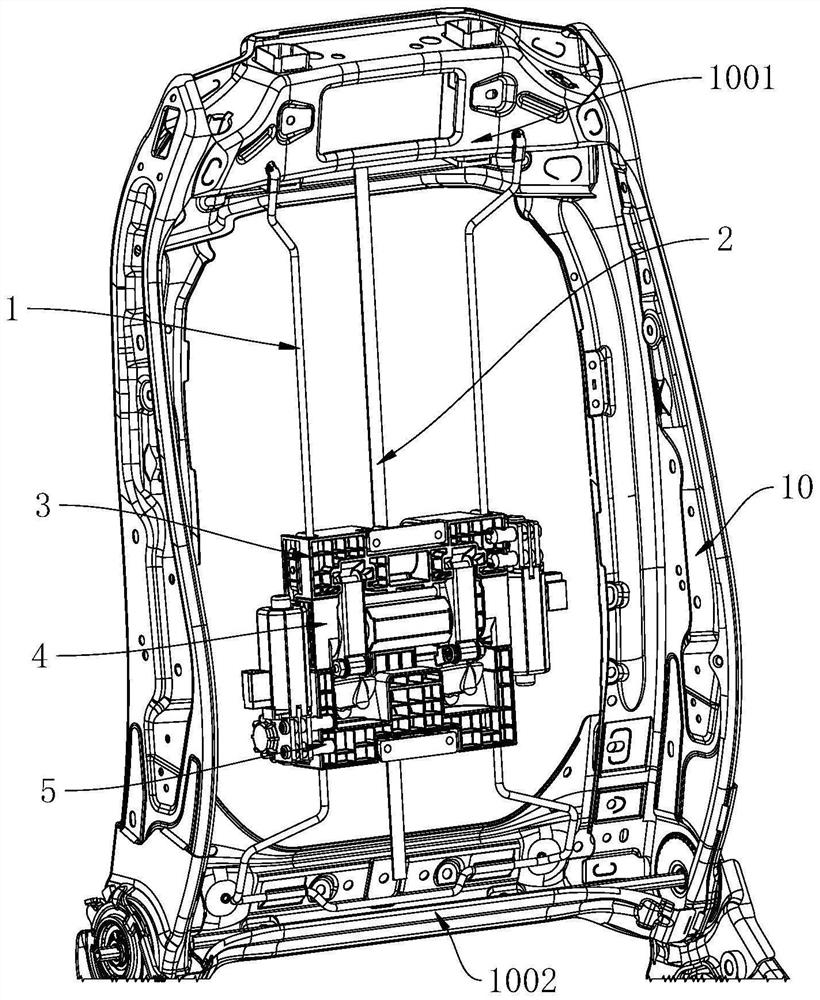

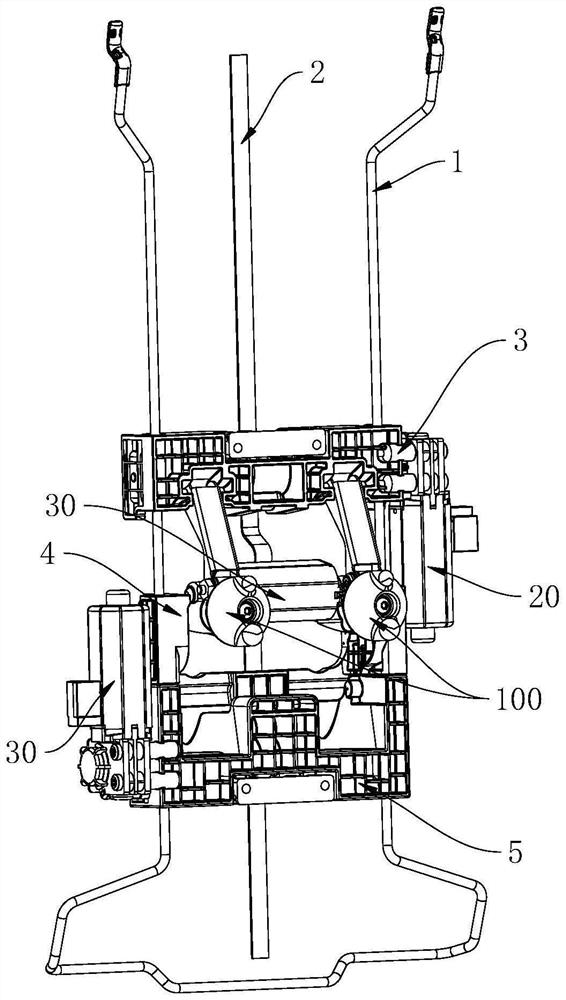

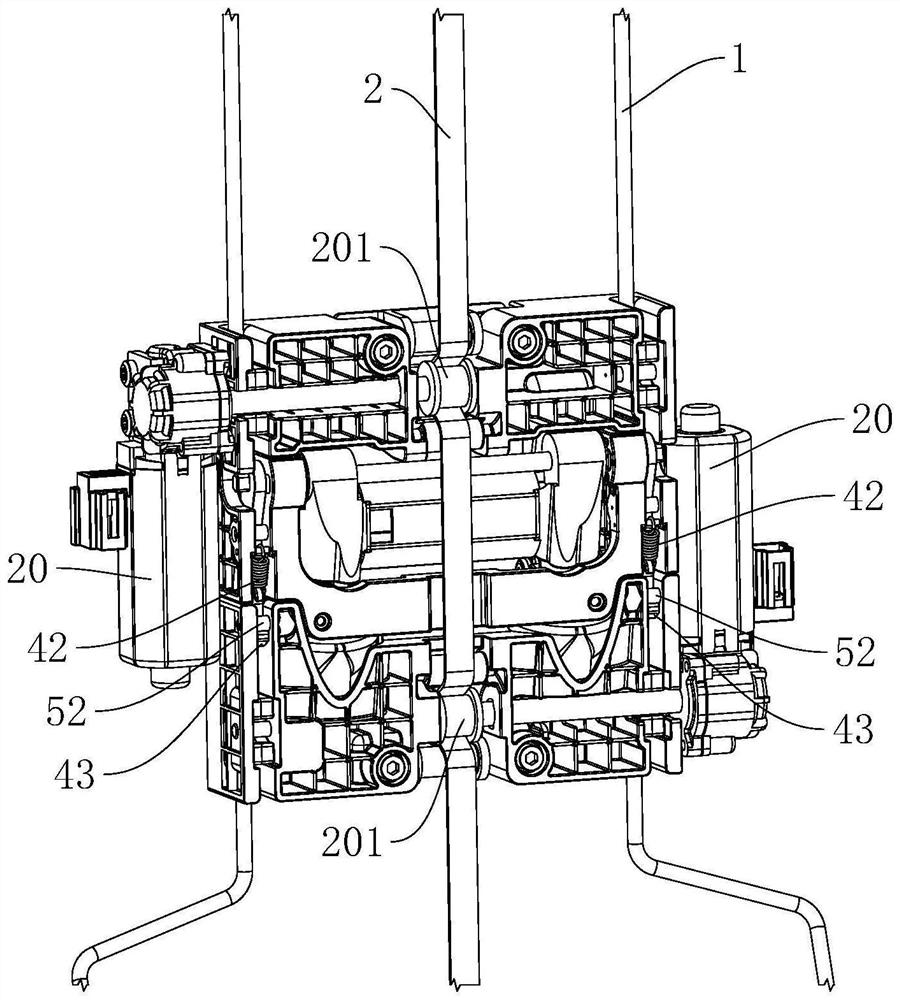

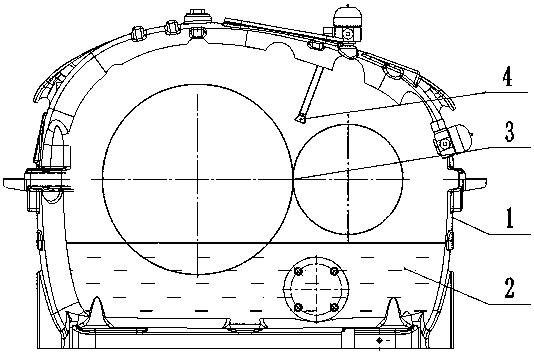

Massage mechanism for seat backrest

The invention provides a seat backrest massage mechanism which comprises a sliding base arranged on a backrest framework, a first sliding assembly, a second sliding assembly and a third sliding assembly, the first sliding assembly, the second sliding assembly and the third sliding assembly are sequentially arranged on the sliding base in a sliding mode, and a first driving assembly is arranged between the first sliding assembly and the sliding base. A second driving assembly is arranged between the third sliding assembly and the sliding base, a massage assembly with a massage head is hinged in the second sliding assembly, a linkage assembly is hinged between the first sliding assembly and the massage assembly, a connecting assembly is arranged between the second sliding assembly and the third sliding assembly, and when the first sliding assembly or the third sliding assembly slides, the linkage assembly is hinged to the massage assembly. When the third sliding assembly slides, the linkage assembly can drive the massage assembly to turn over, and when the third sliding assembly slides, the connecting assembly can drive the second sliding assembly to slide synchronously. According to the seat backrest massage mechanism, the massage head can be turned over by different heights and can also move along the sliding base, so that massage in various modes can be realized, and the seat backrest massage mechanism has a better use effect.

Owner:NOBO AUTOMOTIVE SYST CO LTD

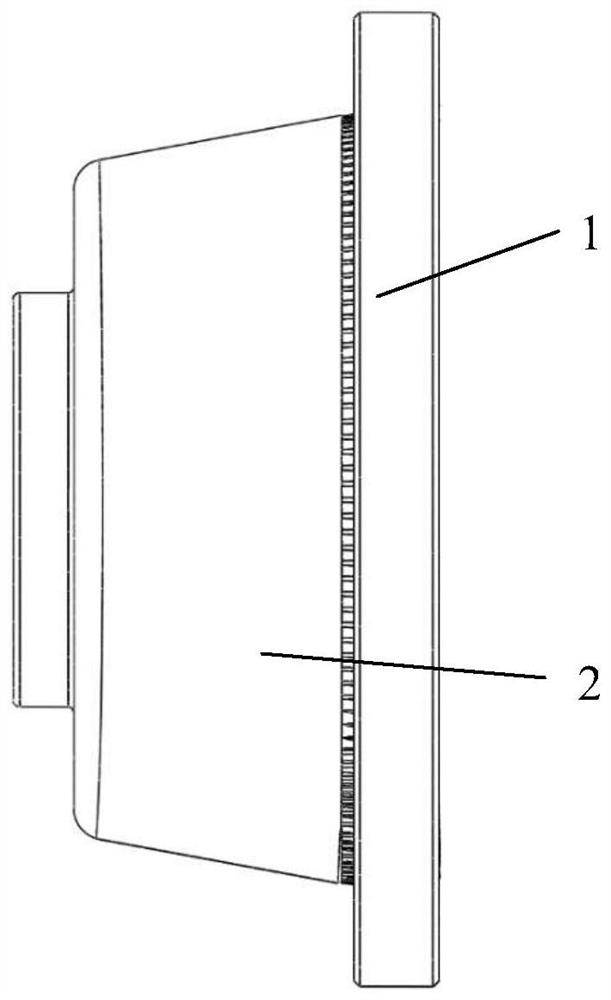

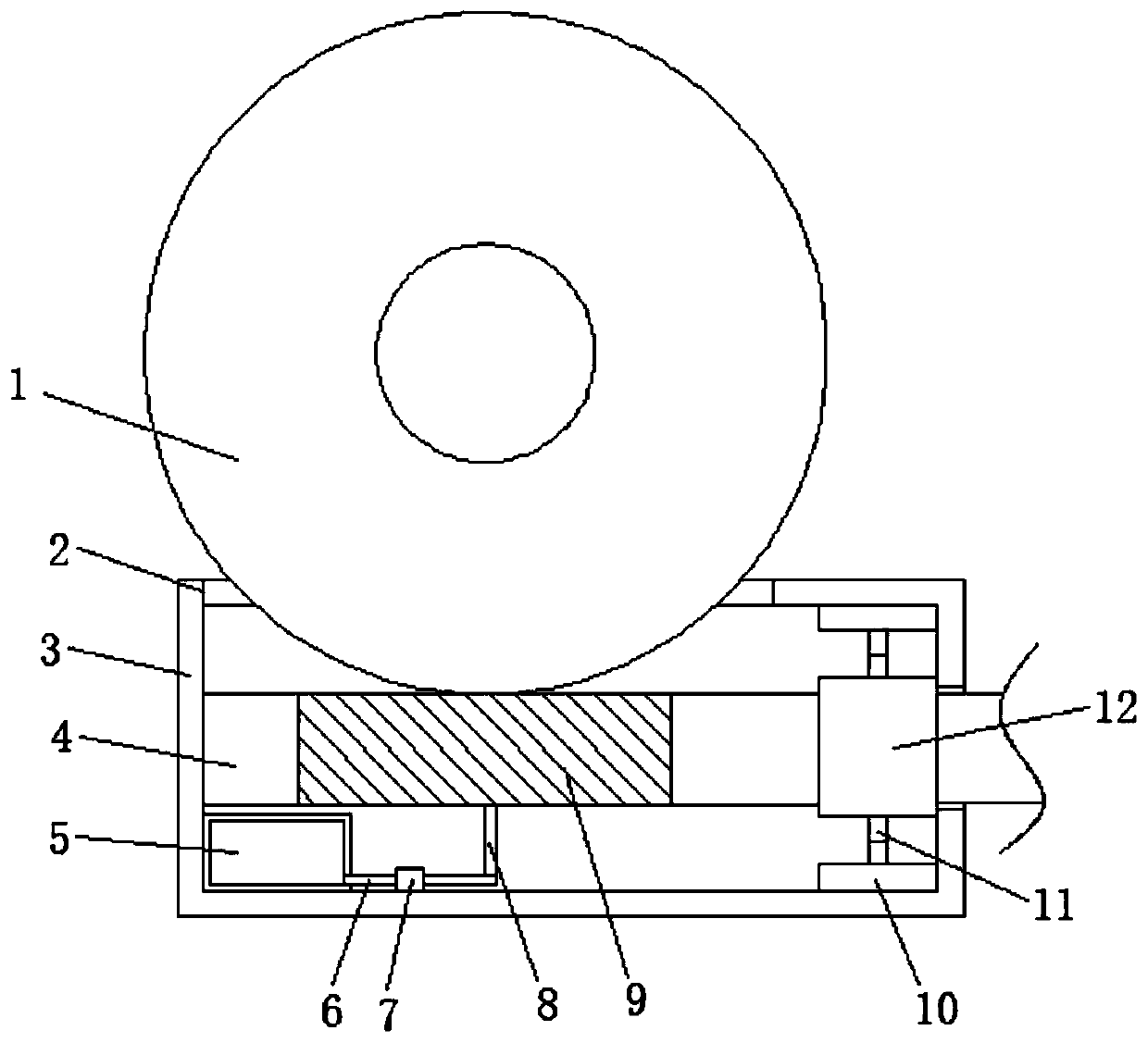

Gear with pitted end face

InactiveCN108825754AReduce the temperatureImprove cooling effectPortable liftingGear lubrication/coolingGear wheelEngineering

The invention relates to a gear with a pitted end face. The surface of a gear pair is provided with gear surface pits, lubricating oil is arranged in a speed reducer housing, the gear pair is immersedin the lubricating oil, and the lubricating oil is sprayed to the gear pair through a lubricating oil jet nozzle. The gear with the pitted end face can improve the heat exchange efficiency, the temperature of the gear is reduced, the meshing effect is improved, the weight reduction is facilitated, in the high-speed rotation process of the gear, the gear with the pits is beneficial for reducing air resistance, the heat exchange area of the lubricating oil is increased, and the temperature reduction effect is obvious.

Owner:柯尼齿轮箱(大连)有限公司

Motor shafts for car wipers

ActiveCN108134477BIncrease vibrationAffect normal useMechanical energy handlingSupports/enclosures/casingsGear wheelEngineering

The invention discloses a motor shaft for automobile windscreen wipers, comprising a horizontal motor shaft. One end of the motor shaft is sleeved with a horizontal fixed cylinder. The motor shaft isrotationally connected to the inner wall of the fixed cylinder. The fixed cylinder is provided with a horizontal connecting slot on one side of the top end thereof. A vertical gear plate is arranged above the motor shaft. The motor shaft is provided with an external thread on the side wall of one side near the gear plate. The external thread and the gear plate are meshed with each other. An oil tank is fixed to the inner wall of one side, near the connecting slot, of the bottom end of the fixed cylinder. One outer end of the motor shaft away from the oil tank is sleeved with a shaft sleeve, and the vertical section of the shaft sleeve is square. The vibration of the motor shaft can be buffered, and the motor shaft can be prevented from vibrating drastically to mismatch the gear plate and affect normal use of windscreen wipers. Moreover, the external thread of the motor shaft can be lubricated, in order to improve the meshing effect of the motor shaft and the gear plate and prevent theproblem that the motor shaft and the gear plate cannot rotate normally after passivation.

Owner:宁波创世轴业有限公司

Plastic kneader

ActiveCN106738413AImprove kneading effectAvoid problems with stuck in the mixing chamberFlueEngineering

The invention belongs to the technical field of packaging, and discloses a plastic kneader. The plastic kneader comprises a fixed base; a top cover is arranged on the fixed base; a press plate is hinged to the side wall of the top cover; a driving transmission cylinder is vertically arranged on the fixed base and penetrates through the top cover; the driving transmission cylinder is in flat key connection with the eccentric position of the top cover; an air pump is externally connected with the upper end of the driving transmission cylinder; a penetrating hole is formed in the fixed base; an air flue communicating with the penetrating hole is arranged inside the fixed base and externally connected with the air pump; a driven transmission cylinder is inserted into the penetrating hole; the cylinder body section, on an inner cavity of the top cover, of the driving transmission cylinder is in flat key connection with a driving stirring piece; the upper end of the driven transmission cylinder extends into the inner cavity of the top cover but is not connected with the top cover; and the section, extending into the top cover, of the driven transmission cylinder is connected with a driven stirring piece. The plastic kneader can engage materials at the dead corners and improve the overall kneading effect of the materials.

Owner:CHONGQING RUITING PLASTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com