Regenerated glass fiber reinforced plastic-polyvinyl alcohol hybrid fiber high-toughness concrete

A technology of polyvinyl alcohol fiber and hybrid fiber, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of increasing the cost of fiber concrete, easily corroded steel fibers, and affecting the strength of concrete. Achieve the effect of realizing resource utilization, easy system dispersion and improving cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

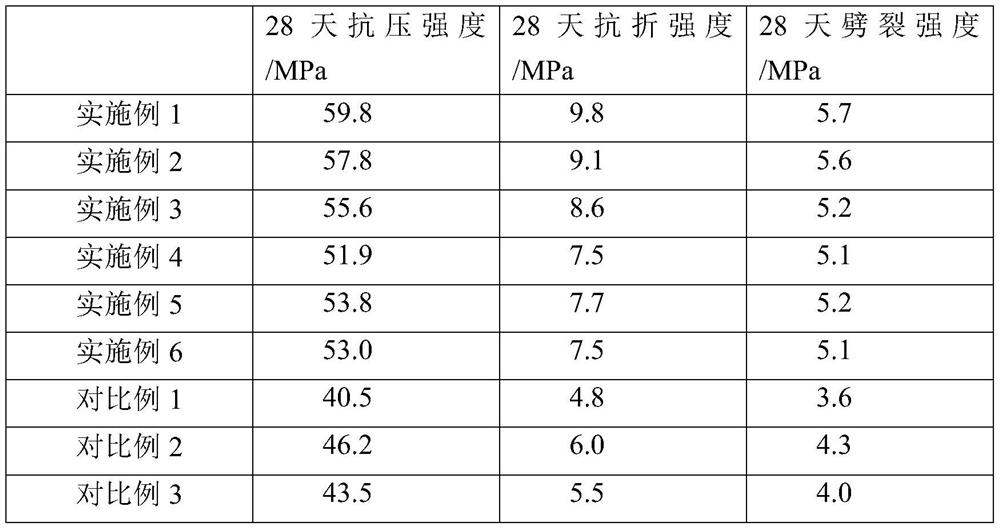

Examples

preparation example Construction

[0031] The preparation method of the regenerated glass fiber reinforced plastic-polyvinyl alcohol hybrid fiber high-toughness concrete of the present invention, concrete steps are as follows:

[0032] (1) Surface treatment of recycled fiberglass fiber:

[0033] First, use distilled water to clean the surface of regenerated FRP fibers of different scales. The mass ratio of distilled water to regenerated FRP fibers is (15:1) to (25:1), and the treatment time is 1h, and then the regenerated FRP fibers are added to the oxidant solution. , so that the resin layer on the surface of the regenerated FRP fiber is etched to varying degrees, and the surface resin will not be completely etched. After 6-10 hours of treatment, take it out and rinse it repeatedly with distilled water, and dry it at 80°C for later use;

[0034] (2) Pre-dispersion treatment of polyvinyl alcohol fiber:

[0035] Take 150 parts of test water and dispersant into a magnetic stirrer, stir for 0.5h, keep the water tem...

Embodiment 1

[0042] A high-toughness concrete with recycled fiberglass-polyvinyl alcohol hybrid fibers, including the following components by weight: 850 parts of cement, 35 parts of silica fume, 1250 parts of fine aggregate, 1800 parts of coarse aggregate, and 15 parts of large-sized recycled fiberglass fiber , 23 parts of medium size, 5 parts of small size, 6.8 parts of polyvinyl alcohol fiber, 7.0 parts of water reducer, 6.3 parts of defoamer, 350 parts of oxidizing agent solution, 0.3 part of dispersant, 400 parts of water. The oxidant solution is 8% sodium hypochlorite solution, and the dispersant is polyacrylamide.

[0043] The concrete steps of preparation method are as follows:

[0044] (1) Surface treatment of recycled fiberglass fiber:

[0045] First, clean the surface of the fiber with distilled water, the mass ratio of distilled water to fiber is 20:1, and the treatment time is 1h, then add the fiber into the oxidant solution, after 8h of treatment, take it out and rinse it re...

Embodiment 2

[0051] A high-toughness concrete with recycled fiberglass-polyvinyl alcohol hybrid fibers, including the following components by weight: 950 parts of cement, 45 parts of silica fume, 1300 parts of fine aggregate, 1950 parts of coarse aggregate, and 13 parts of large-sized recycled fiberglass fiber , 25 parts of medium size, 8 parts of small size, 7.2 parts of polyvinyl alcohol fiber, 6.8 parts of water reducer, 6.8 parts of defoamer, 380 parts of oxidizing agent solution, 0.4 part of dispersant, and 430 parts of water. The oxidizing agent solution adopts 10% sodium hypochlorite solution, and the dispersant adopts methyl cellulose.

[0052] In this embodiment, the surface treatment of regenerated glass fiber reinforced plastic fibers, the pre-dispersion treatment of polyvinyl alcohol fibers and the mixing process of high-toughness concrete with hybrid fibers are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com