Cup-shaped harmonic gear with common tangent type double-circular arc tooth profile and tooth profile design method of gear

A common tangent and double-arc technology, which is applied to components with teeth, belts/chains/gears, mechanical equipment, etc., can solve the problem of not considering the conical deformation characteristics of cup-shaped flexsplines and the inability to use cup-type flexspline teeth Problems such as profile design and relative tooth height of gear teeth are small, so as to achieve the effect of improving mechanical properties and meshing performance, long fatigue life, and increasing meshing contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof:

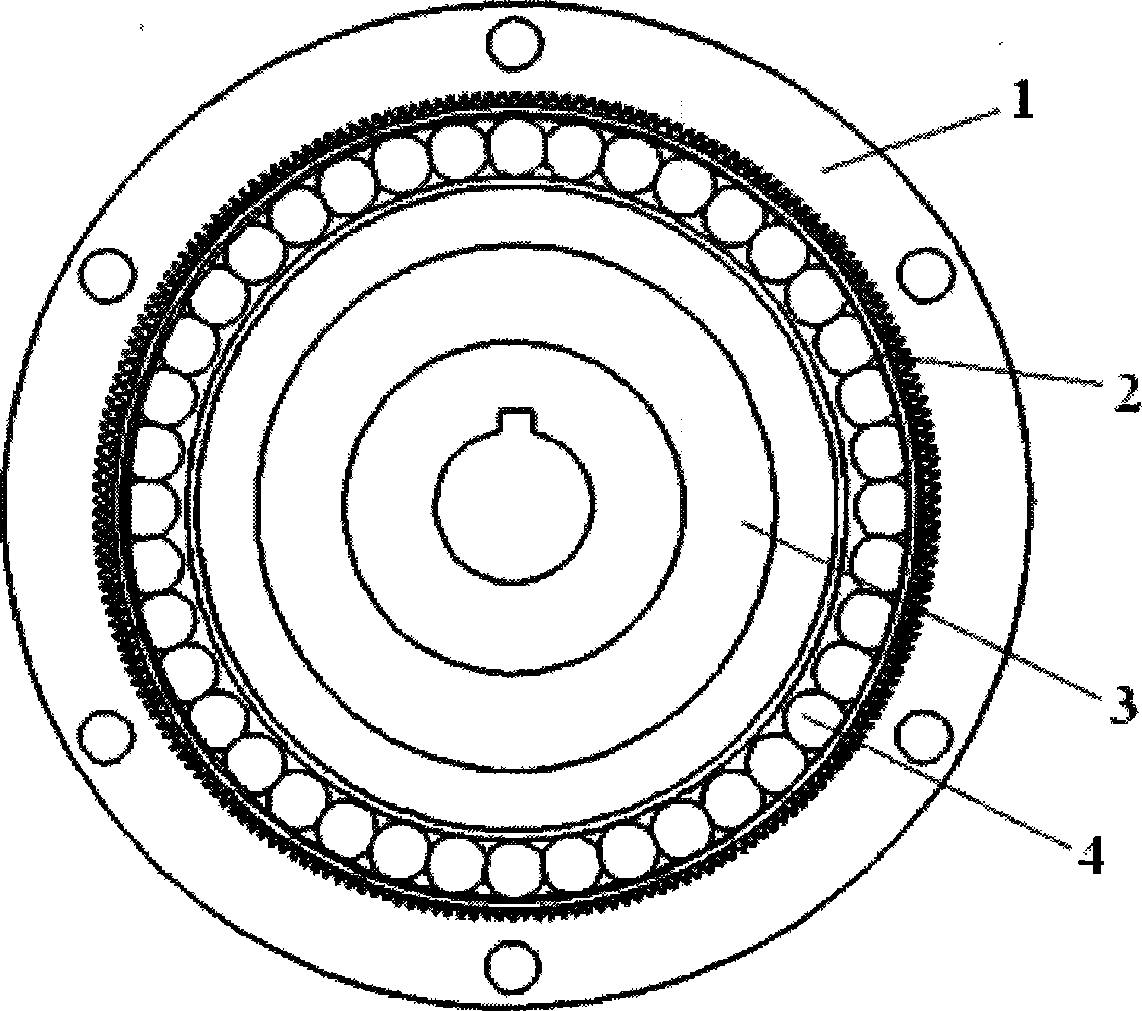

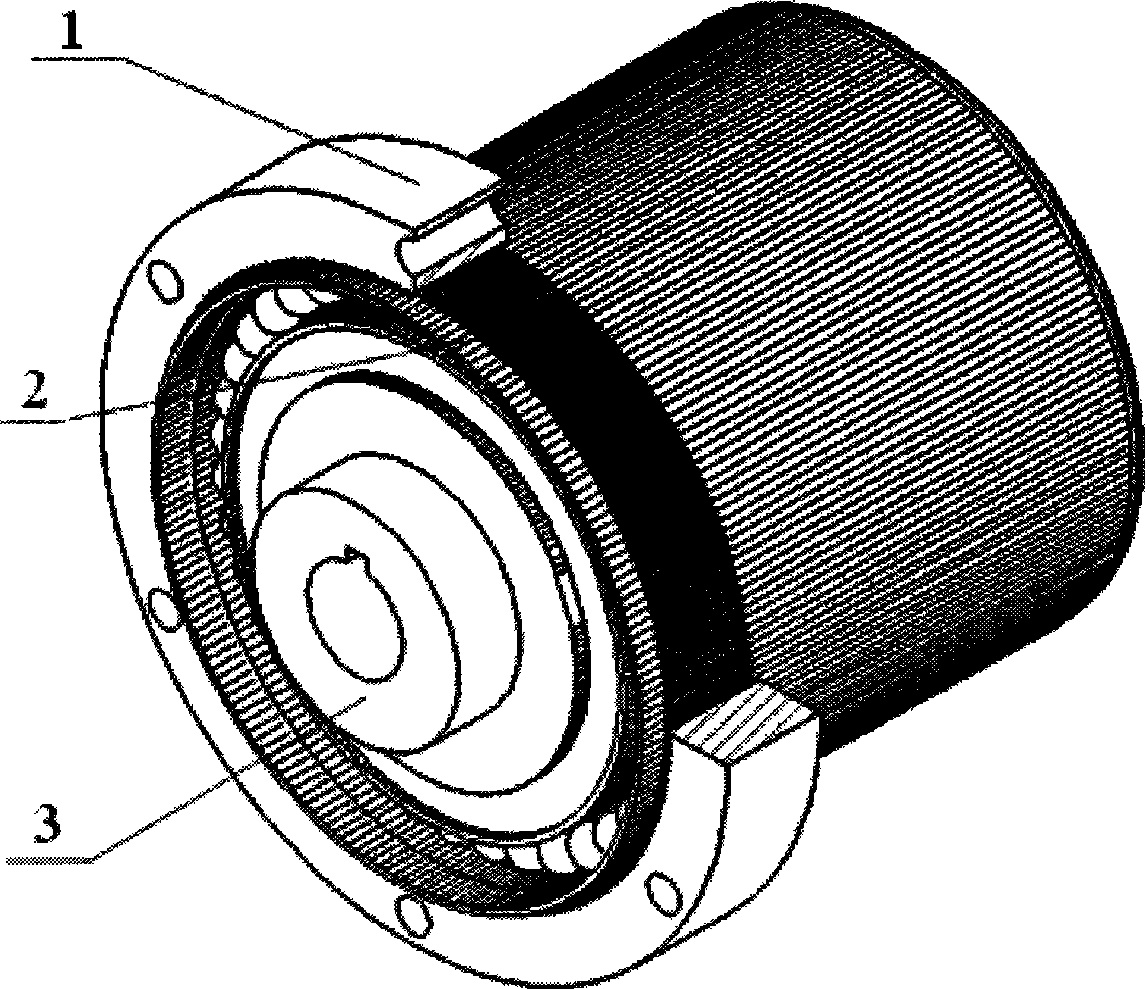

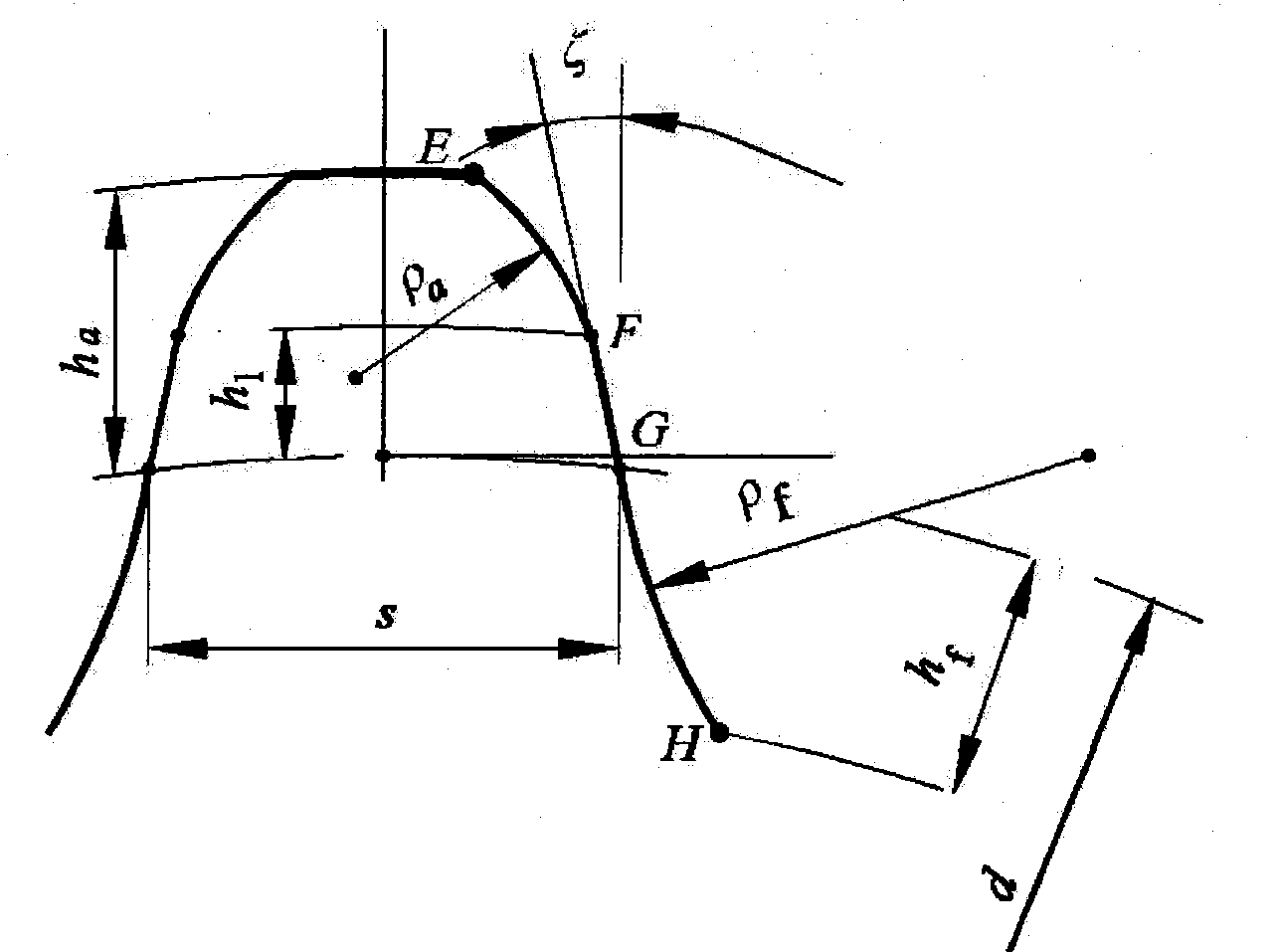

[0036] The present invention has the cup-shaped harmonic gear of common tangent type double arc tooth profile (referring to figure 1 , 2 ), consisting of a rigid spline 1, a flexible spline 2, a wave generator 3 and a flexible bearing 4, the rigid spline 1 is a rigid internal gear, the flexible spline 2 is a cup-shaped cylindrical spur external gear, and the circumference of the rigid spline 1 and the flexible spline 2 The joints are the same, but the number of teeth of the flexible spline 2 is two less than that of the rigid spline 1; the shape of the wave generator 3 is an elliptical cam, and a flexible bearing 4 is installed outside the wave generator 3; after the wave generator 3 is installed in the flexible spline 2 , the teeth in different sections between the long axis and short axis of wave generator 3 are in different states of meshing in or out, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com