Harmonic gear with continuous meshing tooth profile and tooth profile design method thereof

A harmonic gear and tooth shape technology, which is applied in belts/chains/gears, mechanical equipment, special data processing applications, etc., can solve the complicated implementation, calculation error conjugate tooth shape design influence, fitting error fitting function selection Difficulty and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

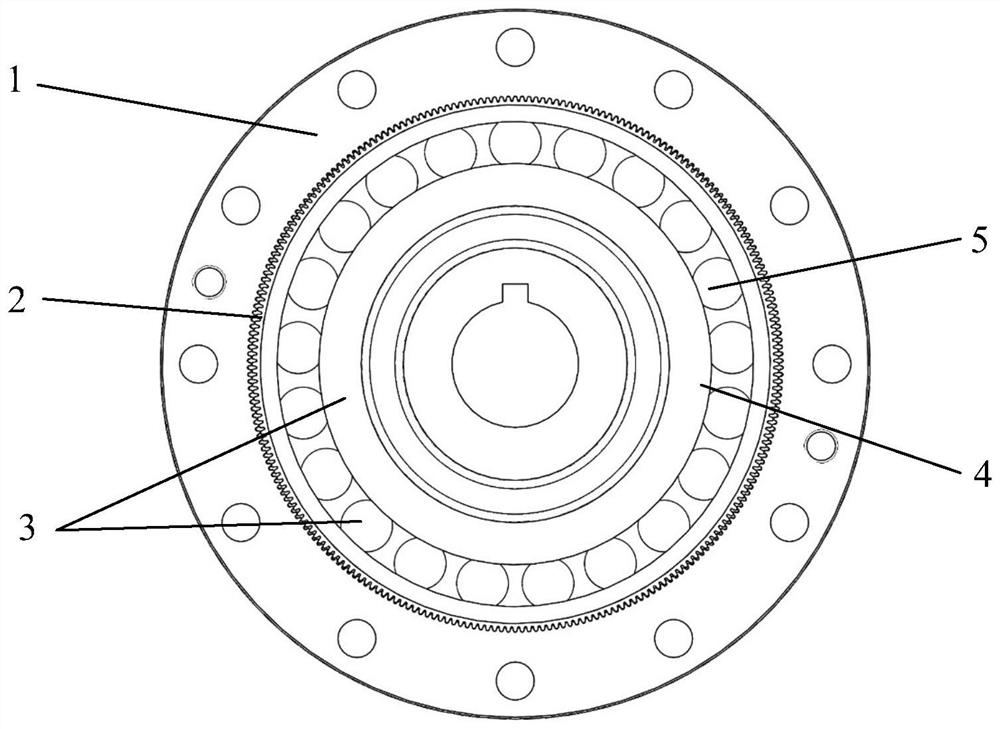

[0074] The present invention provides a harmonic gear with a continuously meshing tooth profile. In this example, the harmonic gear modulus is 0.5mm, the flexible spline is an external gear, and the number of teeth is 240, and the rigid wheel is an internal gear, and the number of teeth is 242. The major axis of the elliptical cam is 91mm, and the minor axis is 89mm, and the equidistant distance from the elliptical cam to the centerline of the flexspline deformation section is 16.555mm.

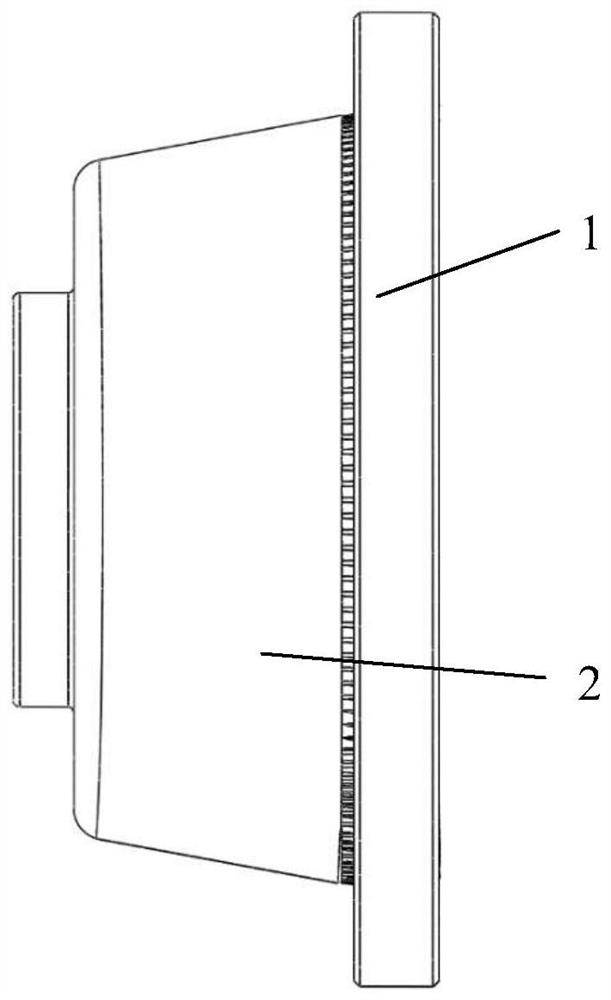

[0075] figure 1 It is the assembly front view of the harmonic gear with continuous meshing tooth profile of the present invention, figure 2 It is the left view of the harmonic gear assembly with continuous mesh tooth profile of the present invention; as figure 1 and 2 As shown, the designed harmonic gear is composed of a rigid wheel 1, a flexible wheel 2 and a wave generator 3, and the wave generator 3 is composed of an elliptical cam 4 and a flexible bearing 5; the elliptical cam 4 is em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com