Dimension lumber tooth-connecting elongating method

A technology of standard timber and tooth connection, which is applied in the field of standard timber lengthening method, can solve the problems of lack of unified specifications and standards, achieve the effect of simple and easy method, and enhance the meshing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

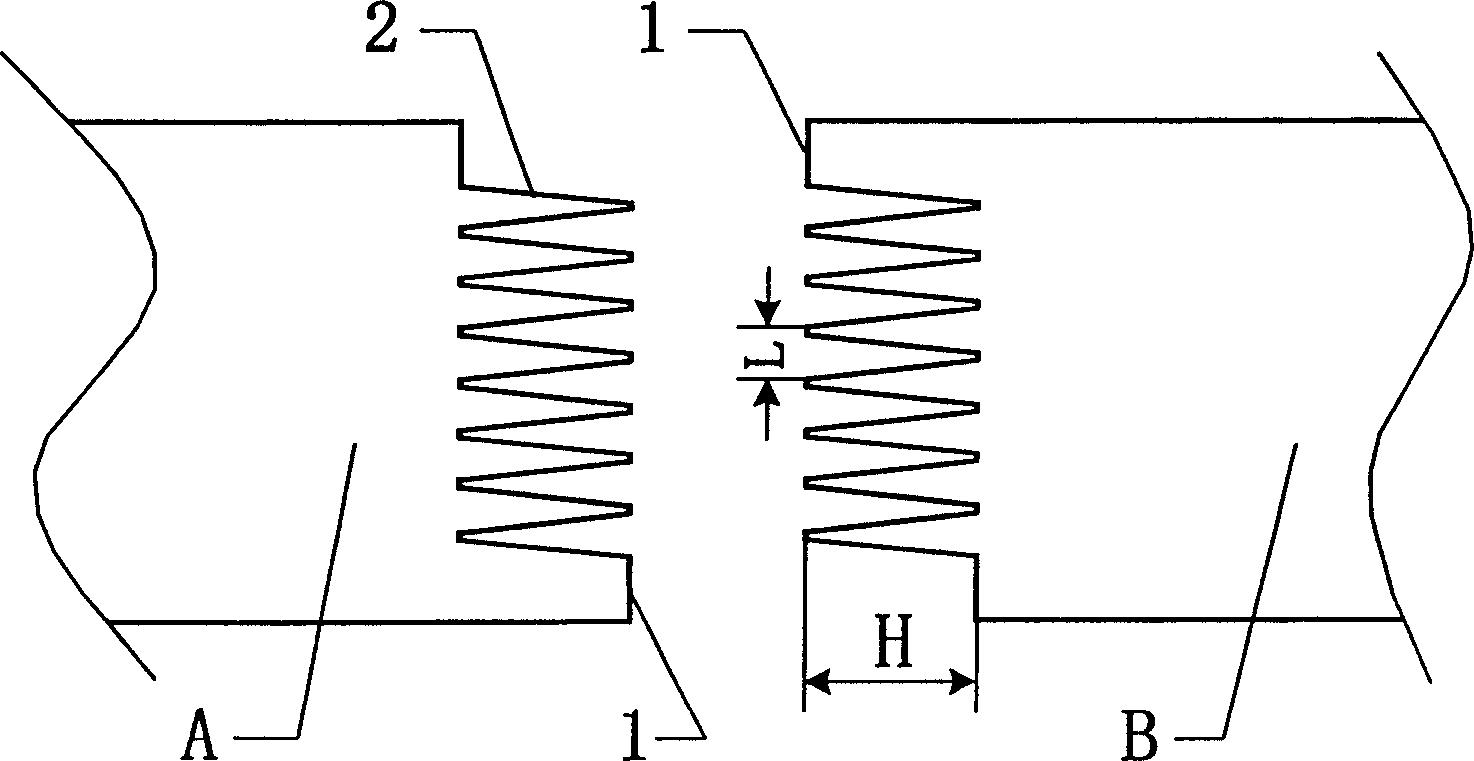

[0012] Below in conjunction with the accompanying drawings, the technical solution of the present invention will be further described in detail by taking the formation of a stud or column with a relatively long length and a relatively high load-bearing requirement in a wooden structure house after being lengthened by the tooth connection method as an example.

[0013] In the construction industry, timber with the same thickness or basically the same thickness is usually called the same specification timber. In general wooden structure houses, stud columns are mostly made of 38mm thick and 89mm wide lumber, columns are made of 38mm thick and 138mm wide lumber, and their lengths are cut as needed. During the construction process, stud columns and columns will produce various short materials, which can no longer be used alone. At this time, the short materials of the same material and the same width can be collected, one or both ends of which are sawed flat, and tooth joints are u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com