Method for improving meshing performance of ultra-short cup-shaped harmonic flexible gear through axial modification

A technology of ultra-short cup type and ultra-short cup, which is applied to components with teeth, belts/chains/gears, portable lifting devices, etc., and can solve the problem of reduced bearing capacity and service life, no meshing, increased flexwheel stress, etc. problems, to achieve the effect of improving meshing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

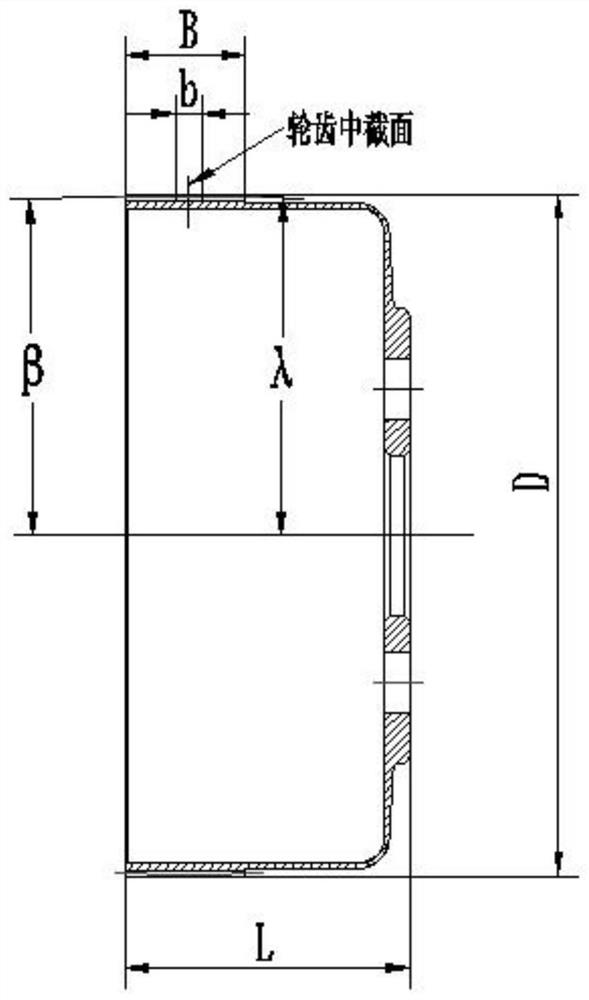

[0012] Embodiments of the invention: see figure 1 , a method for improving the meshing performance of ultra-short cup-type harmonic flexsplines through tooth modification. The method is to modify both ends of the gear teeth on the ultra-short cup type No modification is carried out within the range of the middle tooth width b near the section; the modified gear teeth are divided into three sections within the full tooth width B range, showing a form of high middle and low ends; after tooth modification, front and rear The pitch circle line of the two segments of gear teeth and the center axis of the harmonic flexspline form the first contact angle β and the second contact angle λ, respectively, and the first contact angle β and the second contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com