Assembly line conveying structure for piston rod of hydraulic oil cylinder

A technology of hydraulic cylinder and piston rod, applied in the field of hydraulic cylinder piston rod pipeline conveying structure, can solve the problems of unfixed position, high replacement cost, hard material of transmission belt, etc., and achieve convenient disassembly and assembly of conveyor belt, prolong service life, and simple maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

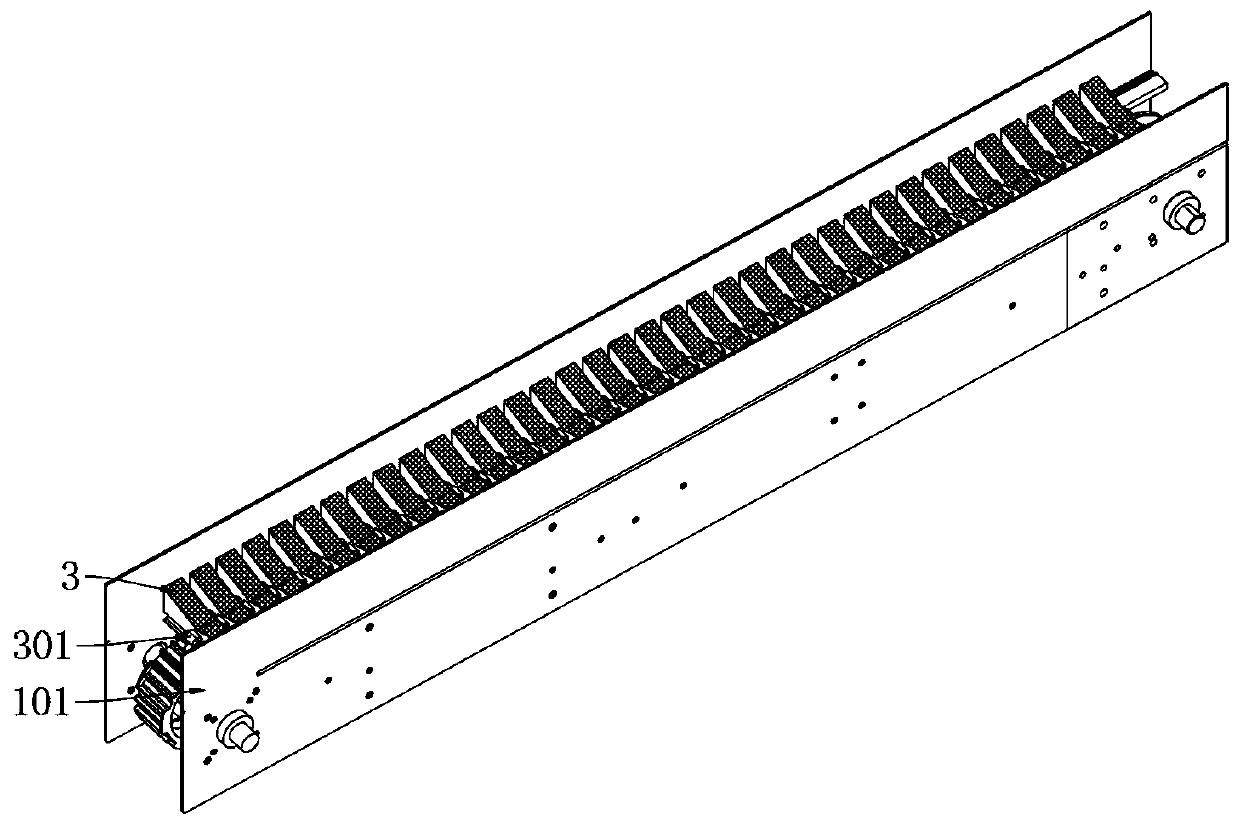

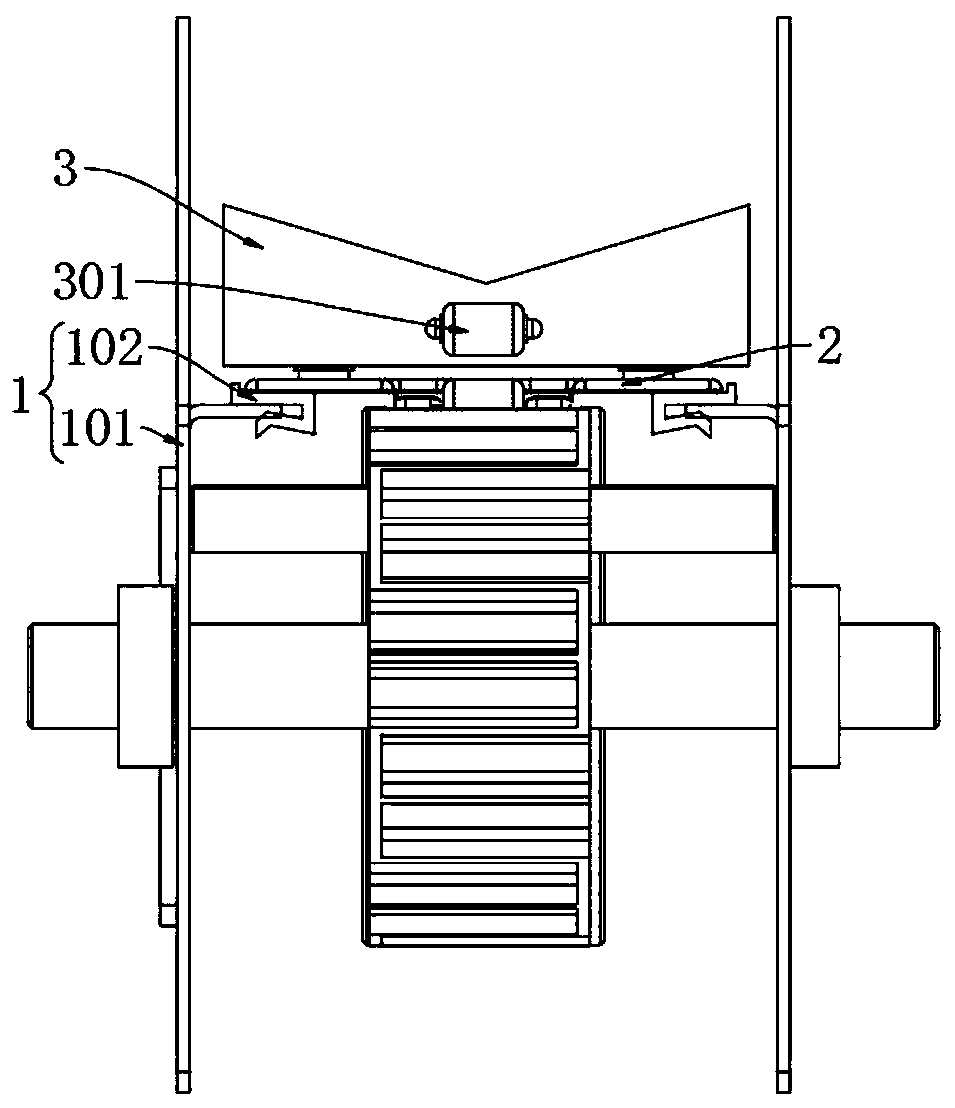

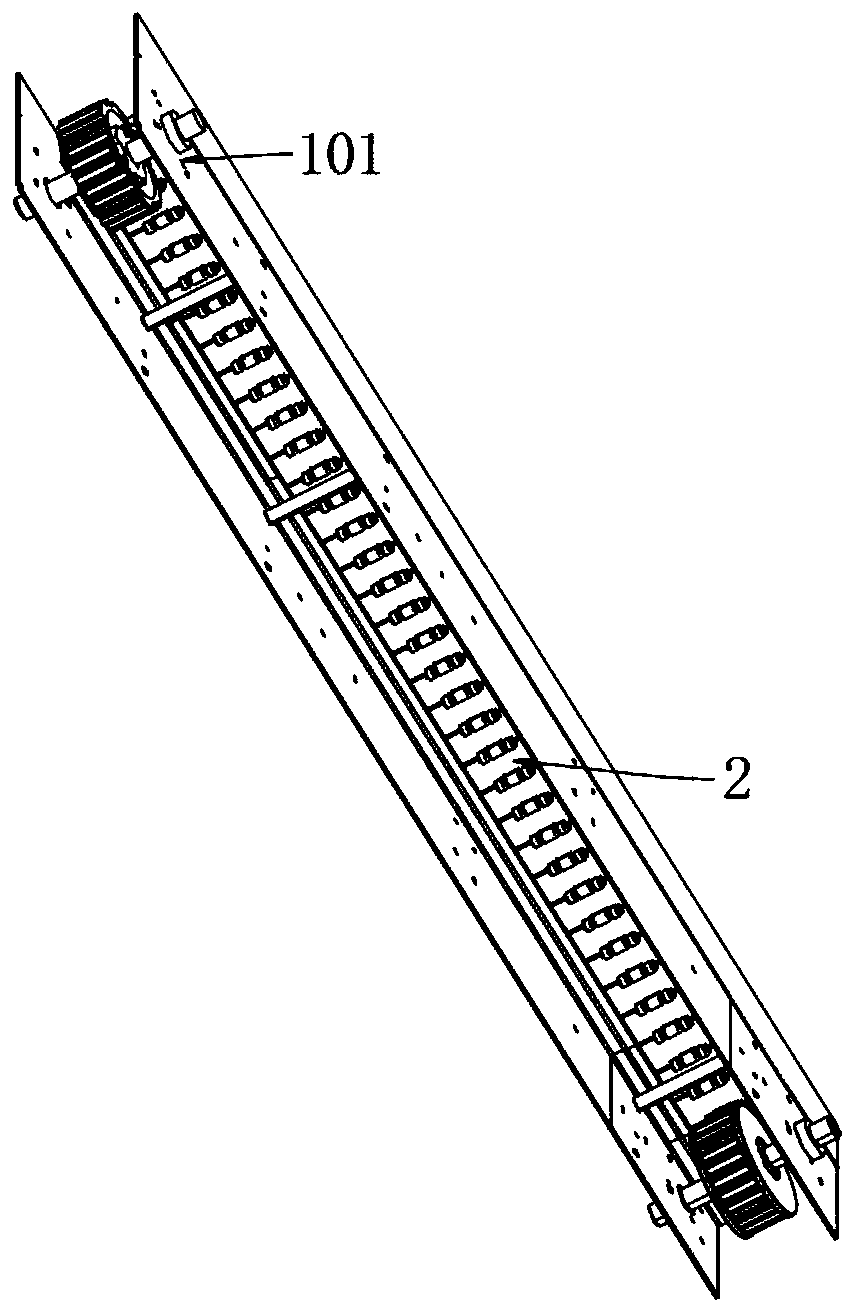

[0032] as attached figure 1 to attach Figure 7 Shown:

[0033] The present invention provides a hydraulic cylinder piston rod assembly line conveying structure, including a supporting mechanism 1;

[0034] The support mechanism 1 is symmetrically installed with two rotationally connected sprockets, and two rectangular support plates are installed on the support mechanism 1; The chain plates 2 are connected to each other through pin shaft hinges; the chain plates 2 form a transmission belt after being connected, and the transmission belt is connected with the sprocket through the hinge, and each chain plate 2 is clamped with a V-shaped fixed block 3; several V The fixed block 3 is also connected to each other through a pin hinge for transmission, and an elastic shaft 4 is placed on the V-shaped fixed block 3, and the V-shaped fixed block 3 is a nylon material lower than the hardness of the rod body.

[0035] Wherein, the support mechanism 1 includes a baffle 101 and a limit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com