Device and method for continuous hydrophobicity of gas diffusion layer of fuel cell

A technology for gas diffusion layer and water, which is applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of labor cost, prolonged working hours, unrealistic, etc., and achieve the effect of avoiding accidental injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

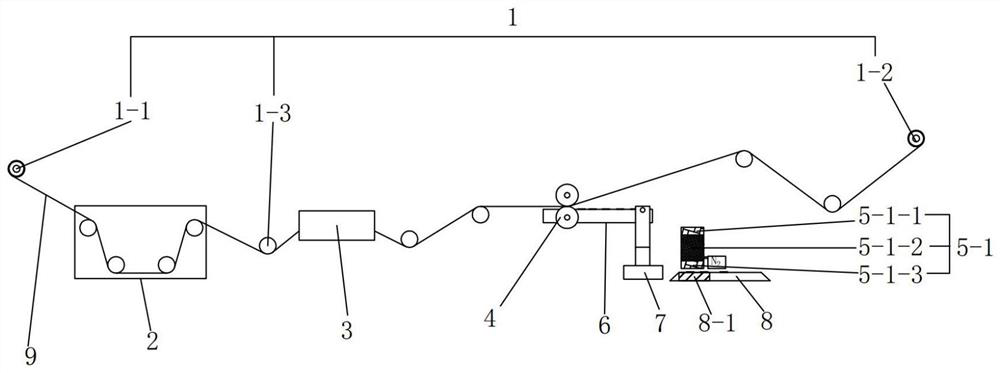

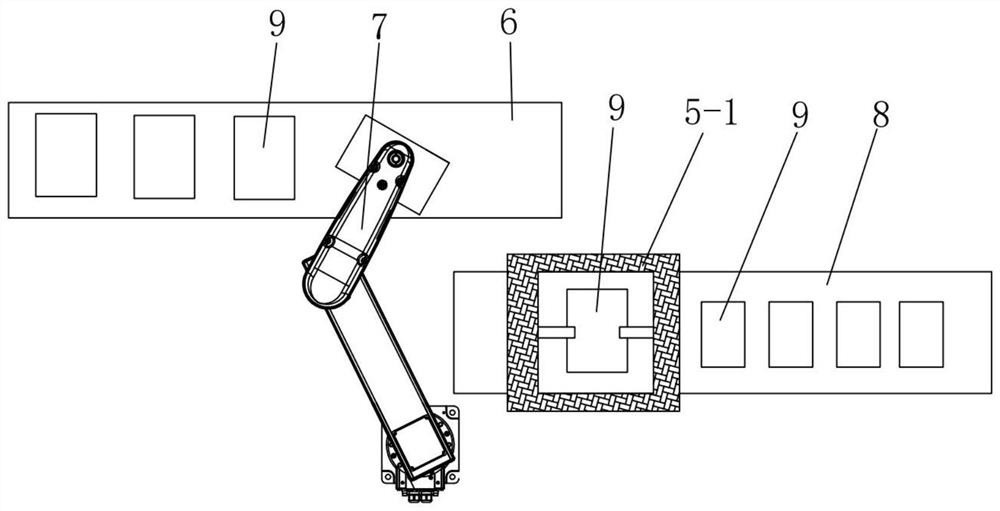

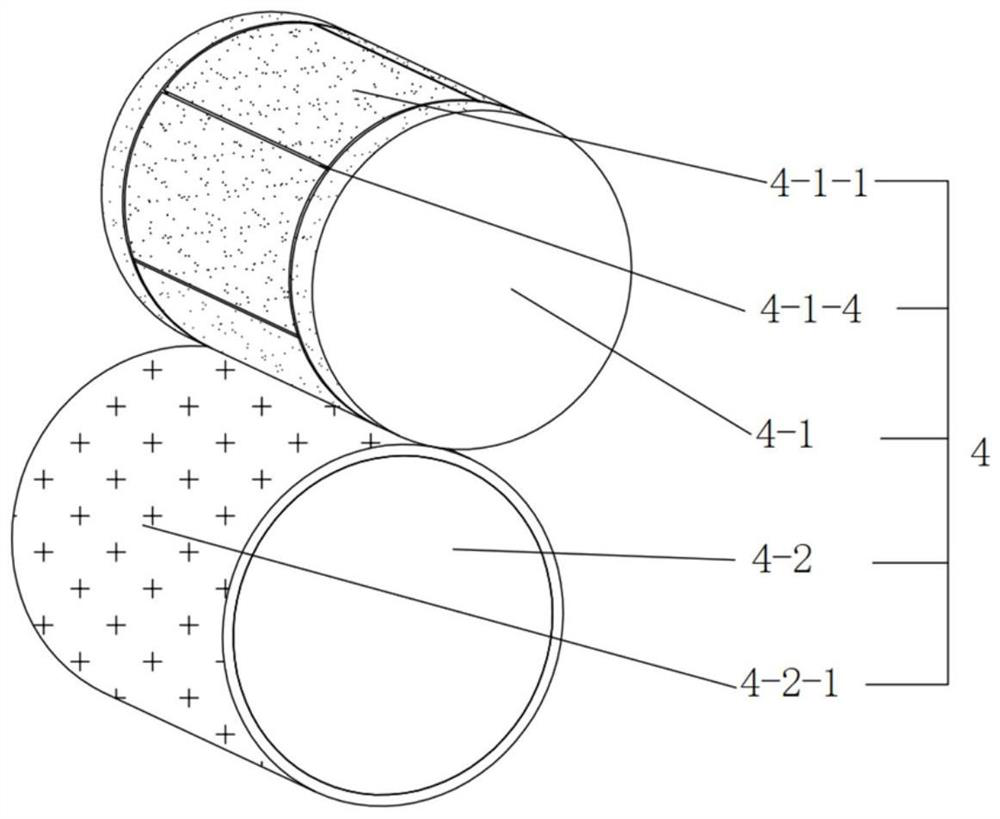

[0045] Example: a gas diffusion layer continuous hydrophobic equipment, such as figure 1 As shown in the figure, it includes a transfer roller mechanism 1 for the flexible carbon paper 9 to be wound and inserted to realize the transfer. The transfer roller mechanism 1 includes an unwinding roller 1-1 at the starting end, a winding roller 1-2 at the end The tensioning drive roller 1-3 between the winding roller 1-1 and the winding roller 1-2, the whole roll of the flexible carbon paper 9 is placed on the unwinding roller 1-1, and its starting ends are respectively tensioned around each The tensioning drive rollers 1-3 are then wound on the winding rollers 1-2, so as to realize the continuous transmission of the flexible carbon paper 9. Continuous transmission, at the same time, the PLC system is also used in this equipment to control the working sequence of the servo motor and the following electrical components through the program, so as to realize intelligent control and oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com