Paper feeding mechanism for flexible plate printer

A printing machine and paper feeding mechanism technology, applied in the direction of object supply, pile separation, thin material processing, etc., can solve the problems of unable to adjust the paper feeding module, time-consuming and laborious, troublesome equipment handling, etc., to achieve convenient paper feeding width, convenient Adjustment, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

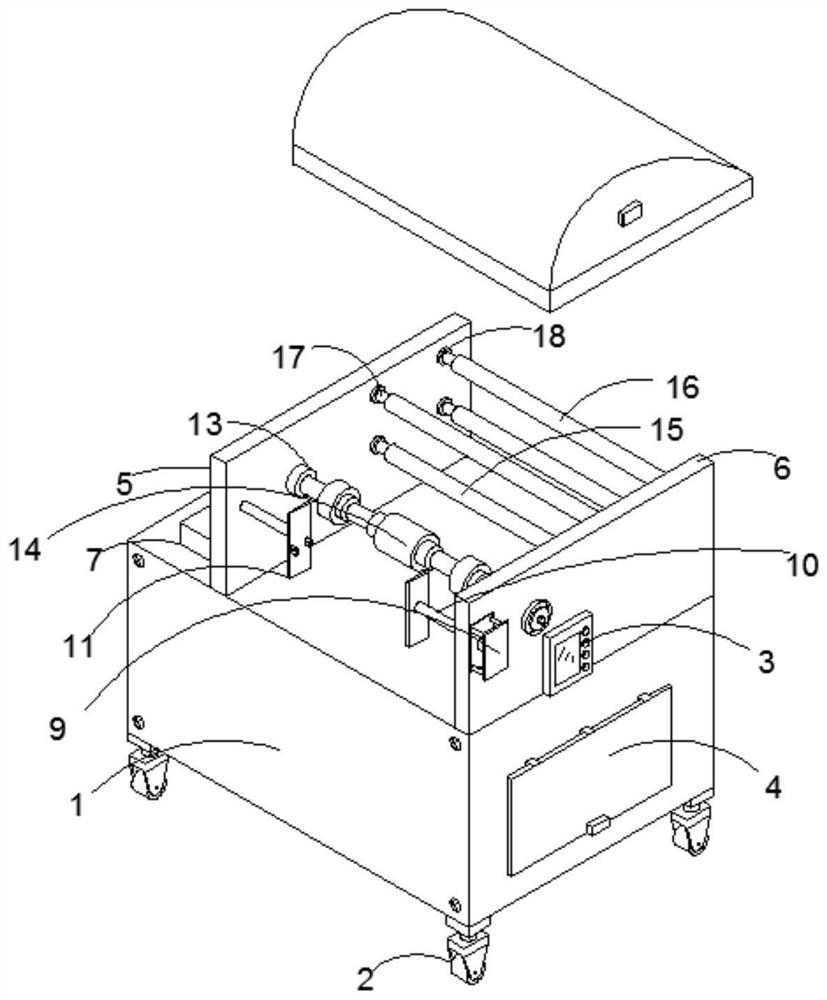

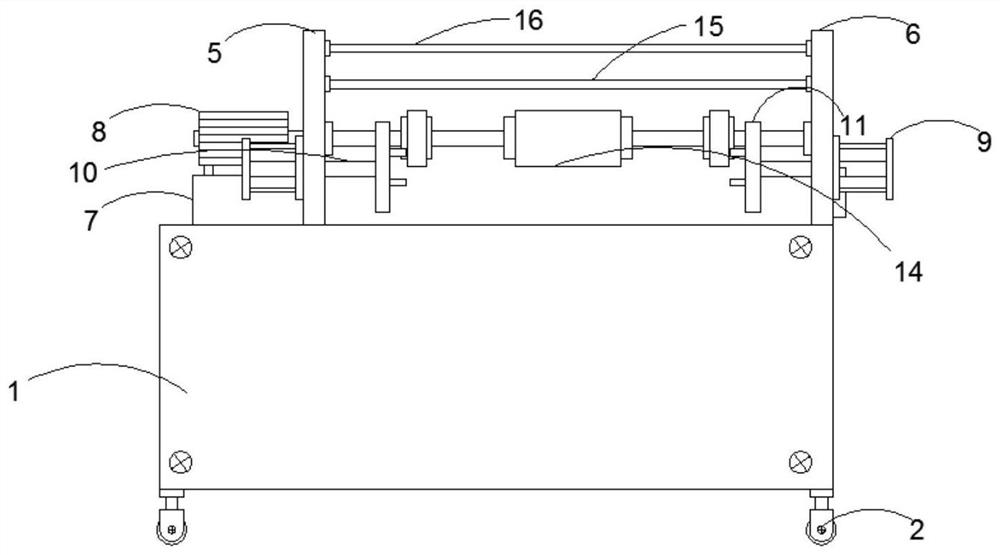

[0027] Such as Figure 1-3 As shown, the present invention provides a paper feeding mechanism for a flexo printing machine, including a workbench 1, self-locking universal wheels 2 are fixedly installed at the four corners of the bottom of the workbench 1, and one side of the workbench 1 is fixedly installed with A control module 3, a storage box 4 is provided at the bottom of the control module 3;

[0028] On the left side plate 5, a right side plate 6 is installed parallel to the right side of the left side plate 5, a support platform 7 is fixedly installed on one side of the left side plate 5, and a paper feeding motor 8 is fixedly placed on the top of the support platform 7, A hydraulic module 9 is fixedly installed on the front side of the left side plate 5, a hydraulic telescopic rod 10 is placed on one side of the hydraulic module 9, and a baffle 11 is fixedly installed on the top of the hydraulic telescopic rod 10;

[0029] Paper feeding module 12, described paper fee...

Embodiment 2

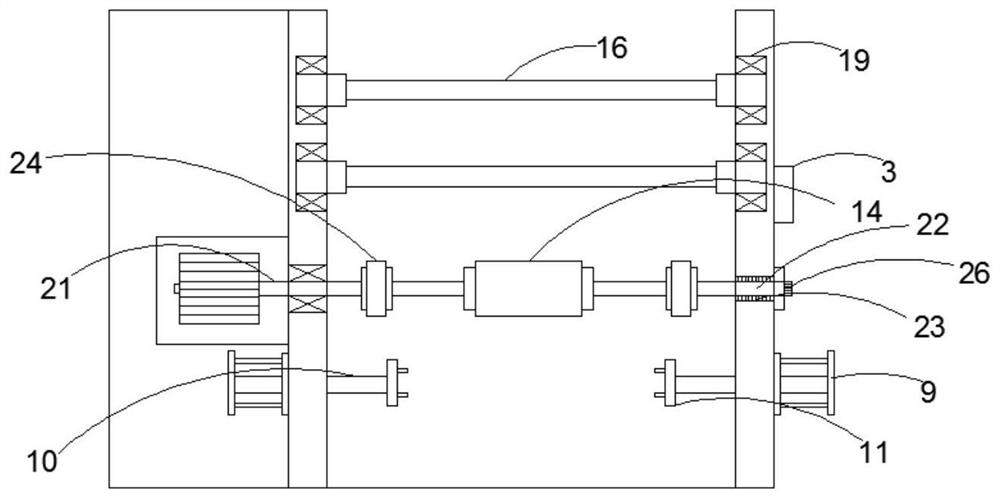

[0038] Such as Figure 1 to Figure 3 As shown, the parts that are the same as or corresponding to those in the first embodiment use the reference numerals corresponding to the first embodiment. For the sake of brevity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is: as image 3As shown, the leftmost end of the connecting shaft 23 and the rightmost end of the machine shaft 21 are provided with fixed disks 24, and the two fixed disks 24 are attached to the outsides of the left and right ends of the roller shaft 14 respectively. The rightmost end of 22 is connected with an operating gear 25, and the left and right ends of the two paper feed rollers A15 and the two paper feed rollers B16 are fixedly connected to the left side plate 5 and the right side plate 6 respectively through eight other fixed bearings, The paper feeding motor 8 is electrically connected to an external power source.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com