A multi-functional orientation-adjustable ink printing device

A azimuth adjustment and ink printing technology, applied in printing, printing presses, rotary printing presses, etc., can solve the problems of poor printing effect and easy to change the printed matter, and achieve the effect of facilitating printing work and preventing movement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

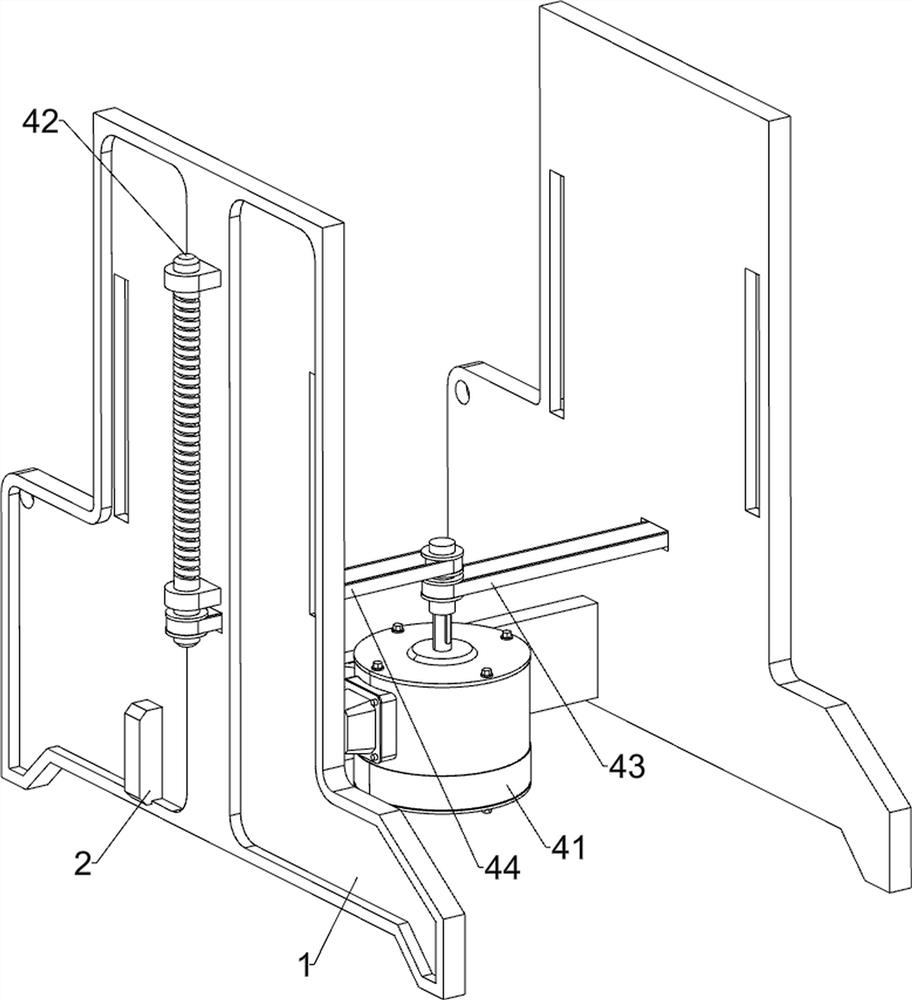

[0028] A multifunctional azimuth-adjustable ink printing device, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a bracket 1, a support plate 2, a guide block 3, a drive assembly 4, a placement assembly 5 and a printing assembly 6. The lower part of the bracket 1 is connected with a support plate 2, and the left and right sides of the rear of the bracket 1 are fixed by bolts. The guide block 3 is provided with a driving component 4 between the bracket 1 and the support plate 2 , a placing component 5 is arranged between the bracket 1 and the driving component 4 , and a printing component 6 is arranged on the bracket 1 .

[0029] When printing is required, first place the object to be printed on the placement assembly 5, and apply ink to some parts of the printing assembly 6, and then the drive assembly 4 can be controlled to start working, and the drive assembly 4 will drive the placement assembly 5 to move up, so that the The printing assembly 6...

Embodiment 2

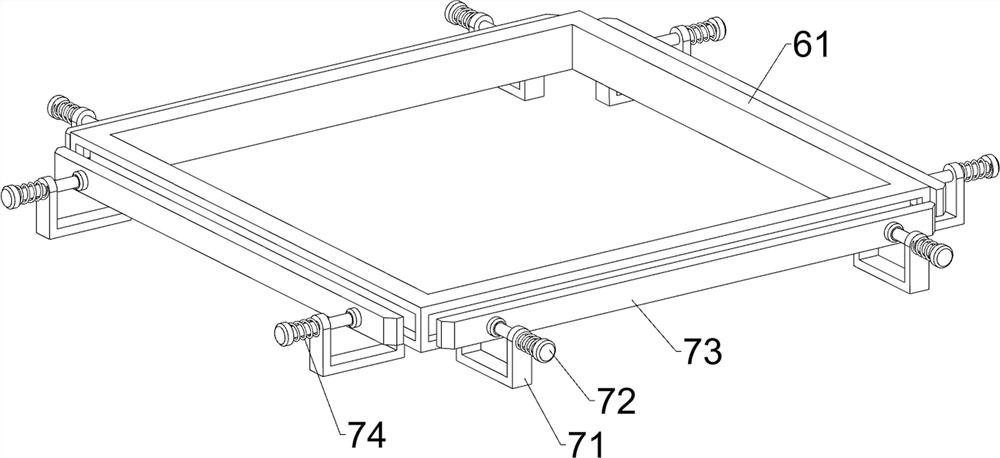

[0037] On the basis of Example 1, as figure 1 , Figure 5 and Image 6 As shown, a clamping assembly 7 is also included. The clamping assembly 7 includes a guide plate 71, a sliding rod 72, a clamping plate 73 and a second spring 74. The outer side of the square frame 61 is symmetrically provided with a guide plate 71, and the upper part of the guide plate 71 is slidably arranged. There is a sliding rod 72 , a clamping plate 73 is connected between the sliding rods 72 on the same side, the clamping plate 73 cooperates with the supporting plate 63 , and a second spring 74 is connected between the sliding rod 72 and the adjacent guide plate 71 .

[0038]When the guide plate 64 needs to be moved, it is necessary to first pull the splint 73 away from the square frame 61 . The movement of the splint 73 will also drive the slide bar 72 to move, and the second spring 74 is stretched. The guide plate 64 can be moved. When the guide plate 64 is moved to a suitable position, the pulli...

Embodiment 3

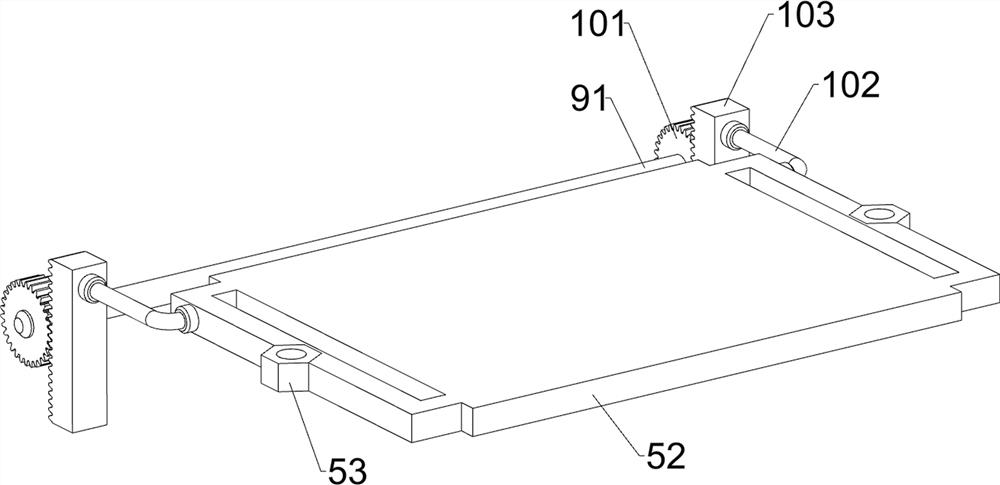

[0042] On the basis of Example 2, as figure 1 , Figure 7 and Figure 8 As shown, it also includes a smearing assembly 9. The smearing assembly 9 includes a rotating rod 91, a guide rail 92, a U-shaped rod 93, a long rod 94, a liquid storage frame 95, a sponge cylinder 96 and a collection frame 97. The rear side of the bracket 1 rotates There is a rotating rod 91, the left and right sides of the rotating rod 91 are connected with guide rails 92, a U-shaped rod 93 is slidably arranged between the guide blocks 3, and a long rod 94 is connected to the rear of the U-shaped rod 93, and the long rod 94 and the guide rails 92 sliding fit, a liquid storage frame 95 is connected between the guide blocks 3, a sponge cylinder 96 is rotatably provided on the front side of the U-shaped rod 93, and a collection frame 97 is connected to the front side of the U-shaped rod 93.

[0043] When the printing mold 67 starts to print, ink can be added to the liquid storage frame 95 first, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com