Continuous adjustable small-diameter steel pipe cutting device

A cutting device and adjustable technology, which are applied in the field of continuous adjustable small-diameter steel pipe cutting devices, can solve the problems that the cutting length cannot be adjusted in real time, the continuous cutting cannot be realized, the danger of manual hand-held cutting, etc., and the scope of application can be increased. , novel design, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

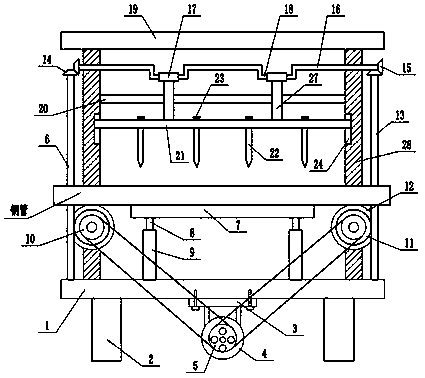

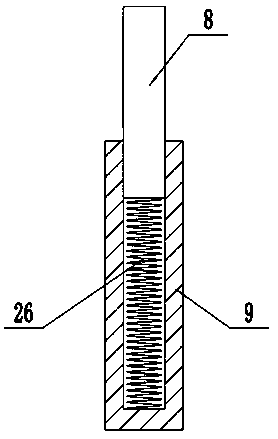

[0028] refer to figure 1 and figure 2 , in an embodiment of the present invention, a continuous adjustable small-diameter steel pipe cutting device includes a fixed base 1, and support legs 2 are installed on both sides of the lower end of the fixed base 1 to realize the support and fixation of this device. A support frame 28 is installed on both sides of the upper end of the base 1, and a top plate 19 is installed on the top of the support frame 28. A motor seat 3 is installed in the middle part of the lower end of the fixed base 1, and a motor 4 is installed at the lower end of the motor seat 3. The output shaft of the motor 4 is connected with a drive Pulley 5, driving pulley 5 is respectively connected with driven pulley 10 by two road pulleys, and driven pulley 10 is coaxially connected with transmission roller 12 and worm wheel 11, and described driven pulley 10, worm wheel 11 and transmission The rollers 12 are all rollingly connected to the middle part of the support...

Embodiment 2

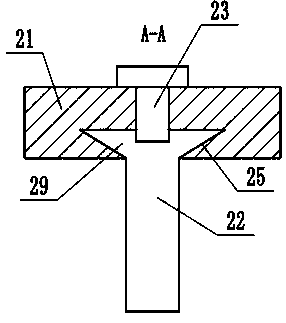

[0031] refer to image 3 , in another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that the top end of the moving cutting knife 22 is set inside the moving groove 25 through the trapezoidal block 29, and the moving groove 25 is a dovetail groove. A trapezoidal block 29 that cooperates with the moving groove 25 is arranged on the top of the moving cutting knife 22, and cooperates with the moving groove 25 of the dovetail groove type, so that the moving cutting knife 22 does not shake when cutting steel pipes, thereby increasing the stability of steel pipe cutting sex.

[0032]In the present invention, when working, the steel pipe is placed on the buffer table 7, and then the motor 4 is started, and the motor 4 drives the driving pulley 5 to rotate, and then the driven pulley 10 is rotated through the belt, so that the worm wheel 11 and the transmission roller 12 rotate synchronously, the transmission roller 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com