Transposition and transferring device for ampuliform containers

A transfer device and container technology, applied in the direction of packaging, conveyors, conveyor objects, etc., can solve the problems of complex structure, inconvenient picking and placing, and limited application, and achieve the effects of improving transmission efficiency, novel structure, and ingenious conception

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

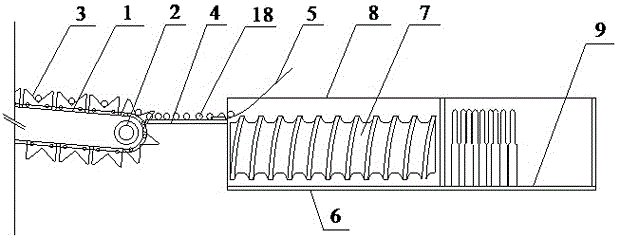

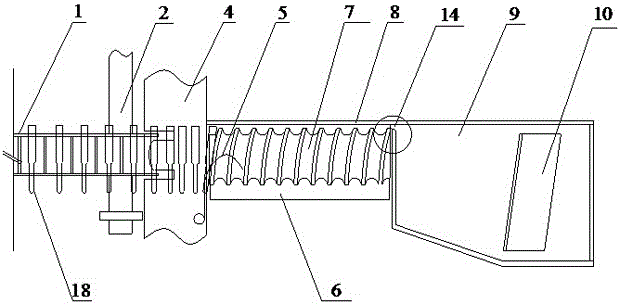

[0037] refer to Figure 1~Figure 6 , a transposition transfer device for bottle-shaped containers, including a flat transmission mechanism for horizontal transmission of bottle-shaped containers, a transposition mechanism for converting flat-position bottle-shaped containers into an upright state, and a transposition mechanism for vertical-position bottle-shaped containers The vertical transfer mechanism and the discharge mechanism for sorting and discharging the vertical bottle-shaped containers, the horizontal transmission mechanism, the transposition mechanism, the vertical transfer mechanism and the discharge mechanism are connected in sequence.

[0038] The horizontal transmission mechanism can adopt a belt conveyor, but considering the fixation of the bottle-shaped containers to prevent the bottle-shaped containers from colliding with each other, the present invention adopts a chain-plate conveyor, which includes a frame and a conveyor belt composed of multiple interconne...

Embodiment 2

[0048] refer to Figure 7 , the bottle-shaped container transposition transfer device described in this embodiment includes a horizontal transmission mechanism, a transposition mechanism, a vertical transfer mechanism and a discharge mechanism connected in sequence. The difference from Embodiment 1 is:

[0049] Both sides of the chain conveyor belt 1 are provided with bottle-shaped container support side plates 11 .

[0050] The above-mentioned bottle-shaped container support side plate 11 is parallel to the transmission chain 1, and one end is movably connected with the rotating shaft, and extends to the bottle slide plate, which is used to assist in supporting a longer end of the bottle-shaped container, so that the bottle-shaped container can be transported during the transmission process. Even if there is an error in the placement of the bottle-shaped container on the conveyor chain 1, or the center of gravity is not on the conveyor chain 1, the bottle-shaped container wil...

Embodiment 3

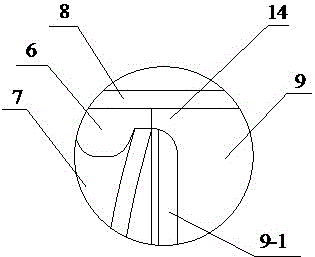

[0052] refer to Figure 8 , the bottle-shaped container transposition transfer device described in the present embodiment includes a flat transmission mechanism, a transposition mechanism, a vertical transfer mechanism and a discharge mechanism connected in sequence, and the vertical transfer mechanism is composed of a base plate 6, a screw transfer roller 7 Composed of a guide side plate 8, the spiral transfer roller 7 is connected to the bottom plate 6 through a shaft seat, and one end is connected with a reduction motor, the guide side plate 8 is located on one side of the bottom plate 6, and is arranged parallel to the screw transfer roller 7, The difference with embodiment 1 is:

[0053] The above-mentioned base plate 6 is provided with a guide groove 12; the guide groove 12 is used to guide the bottle-shaped container to move in a preset direction without deviating from the limit range of the guide groove 12; specifically, the shape of the guide groove 12 is strip-shaped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com