Space curve engagement transmission mechanism

A technology of space curve and transmission mechanism, applied in transmission devices, mechanical equipment, belts/chains/gears, etc., can solve the problems of unsteady transmission, unstable performance, complex structure, etc., and achieve continuous and stable meshing transmission, structure The effect of simple, simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

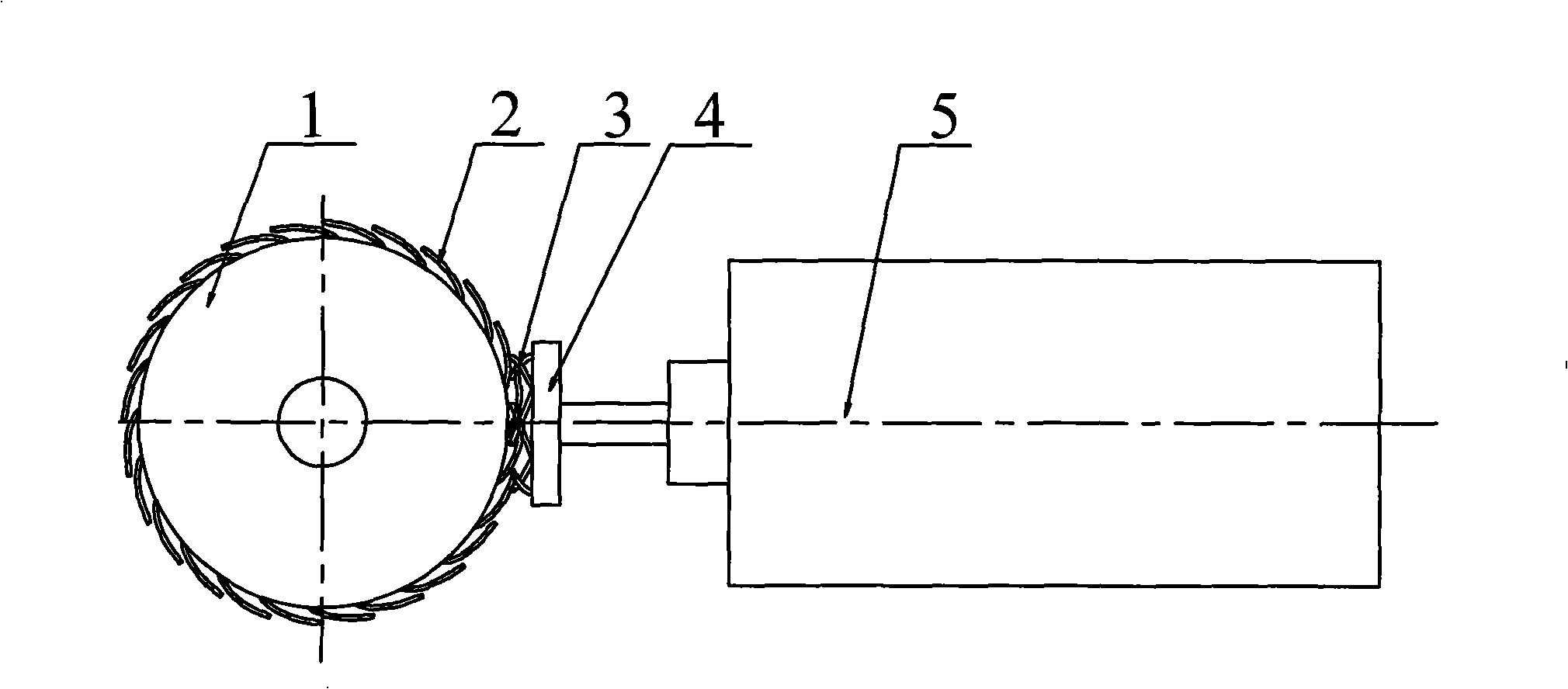

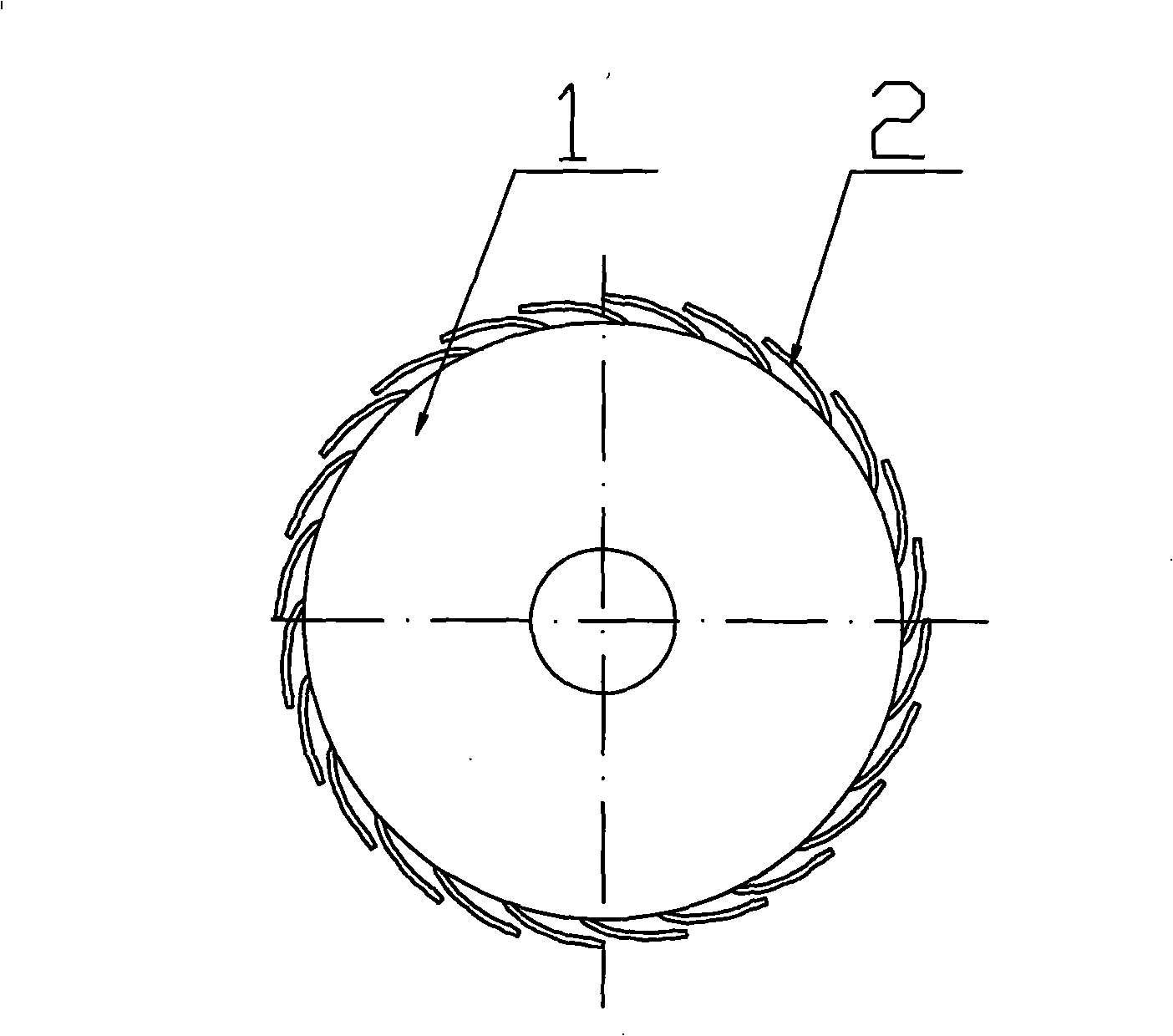

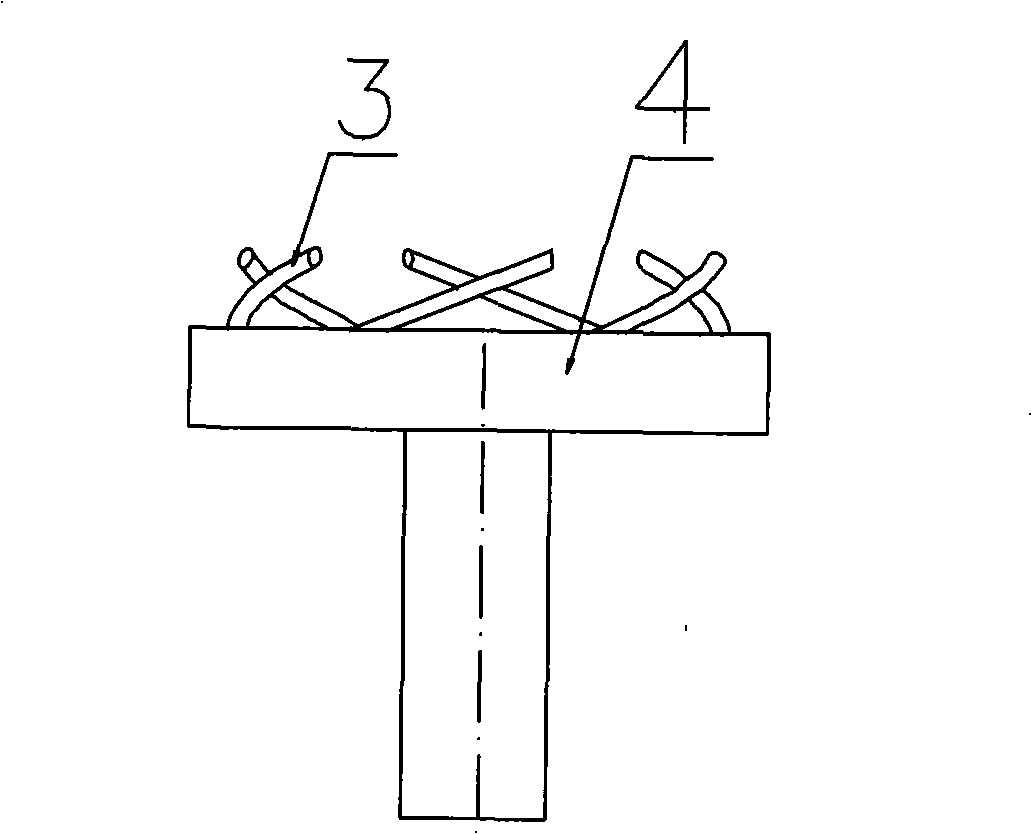

[0019] The method and mechanism of the invention are suitable for providing drivers for micro-mechanical devices. like figure 1 As shown, the space curve meshing transmission mechanism is composed of a driven wheel 1, a driven wheel hook bar 2, a driving wheel hook bar 3, a driving wheel 4, and a micro-motor 5. The driving wheel 4 is connected with the main shaft of the micro-motor 5, and the driven wheel 1 is connected with the rotating shaft of the driven device. The transmission pair is formed between the driving wheel 4 and the driven wheel 1 by the driving wheel hook bar 3 and the driven wheel hook bar 2 .

[0020] The transmission principle of the space curve meshing transmission mechanism is: the driving wheel rotates under the drive of the micro-motor, and a pair of driving wheel hook rods contact with the driven wheel hook rods to start meshing. At this time, the driven wheel hook rods hinder the driving wheel hook rods Motion, the interaction between them produces ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com