Three-section electric connecting guide wire for electric light source and its manufacturing process

A manufacturing process and technology of electric light source, applied in the field of lighting, can solve the problems of increasing production cost, generating air bubbles, easy air leakage, etc., and achieving the effect of saving production cost, improving production efficiency, and solid welding point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

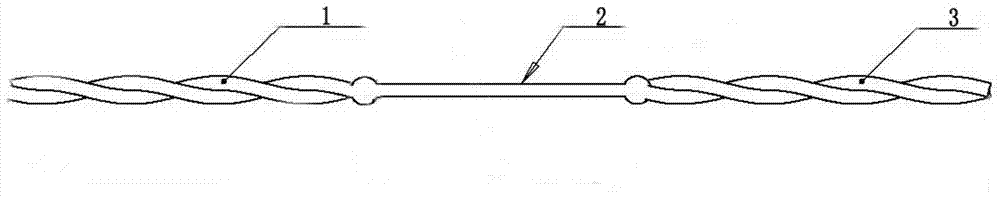

[0028] Such as figure 1 As shown, the electric light source uses three electrically connected guide wires, including an inner guide wire 1, a sealing wire 2, and an outer guide wire 3. The inner guide wire 1 is welded to one end of the sealing wire 2, and the other end of the sealing wire 2 is connected to the outer guide wire. The guide wire 3 is welded and connected, the inner guide wire 1 and the outer guide wire 3 are formed by twisting at least two strands of conductive metal monofilaments along the central axis, and the sealing wire 2 is du magnesium wire. In this embodiment, the diameter of the inner guide wire is 0.6mm-1.7mm, and the length is 6mm-120mm; the diameter of the sealing wire is 0.1mm-0.4mm, and the length is 2mm-30mm; The guide wire length is 18mm-120mm.

[0029] In this embodiment, the inner guide wire is twisted from copper-plated nickel wire, the diameter of the copper-plated nickel wire is 0.2mm-0.6mm, the twisting distance is 6mm-12mm, the pitch ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com