Tension balance type flying shuttle and balance assembly

A balanced component and balanced technology, which is used in textiles, textiles, papermaking, looms, etc., can solve the problems of easy tearing, large changes in thread tension, low thread tension values, etc., to achieve the effect of not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with specific embodiment and accompanying drawing, the present invention is further elaborated and illustrated:

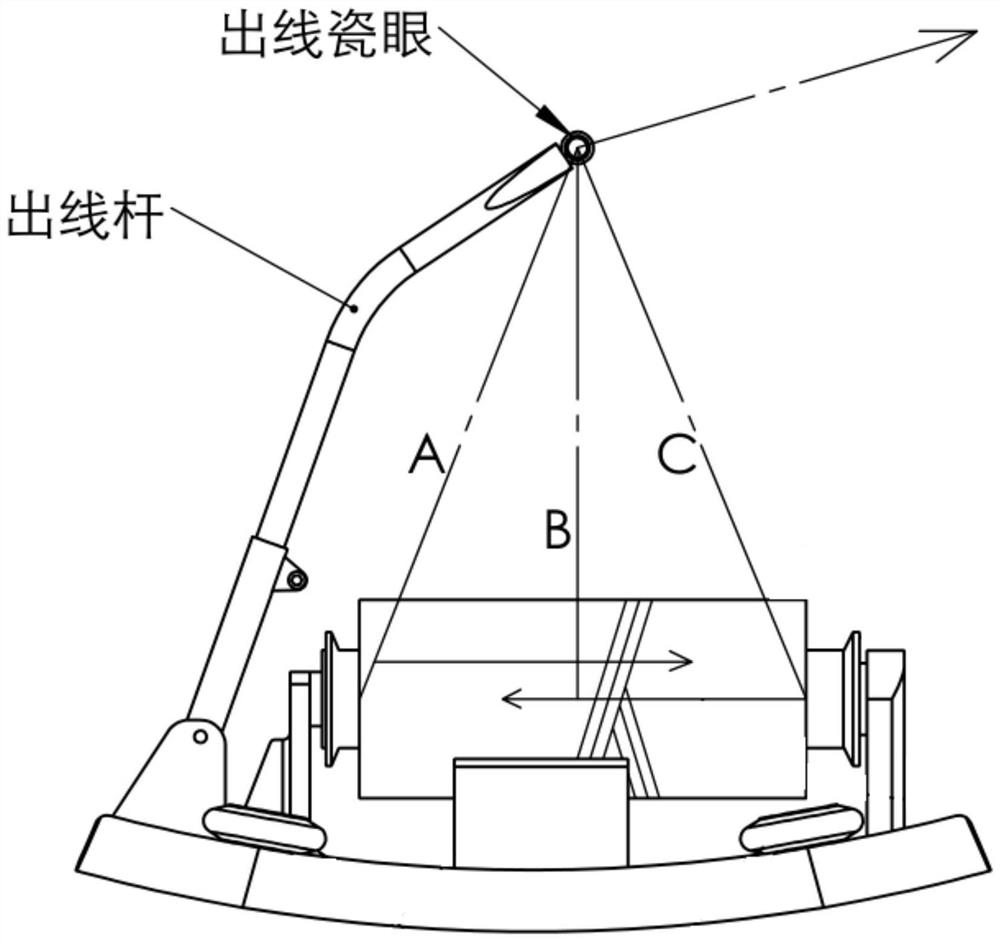

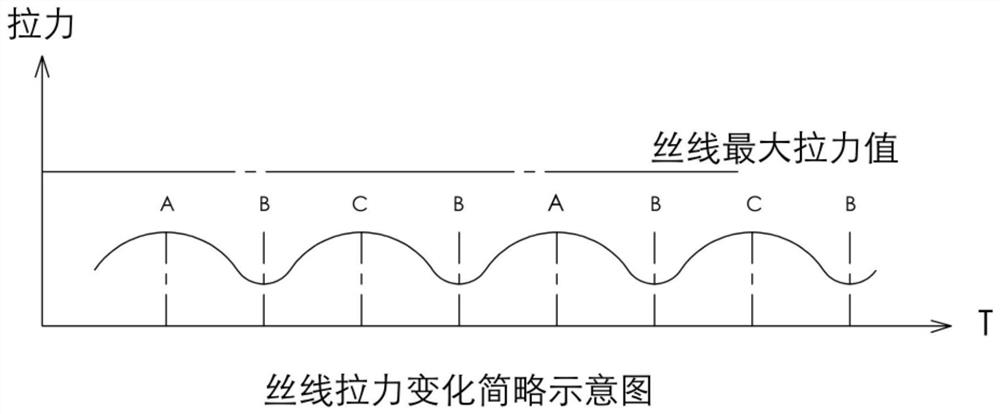

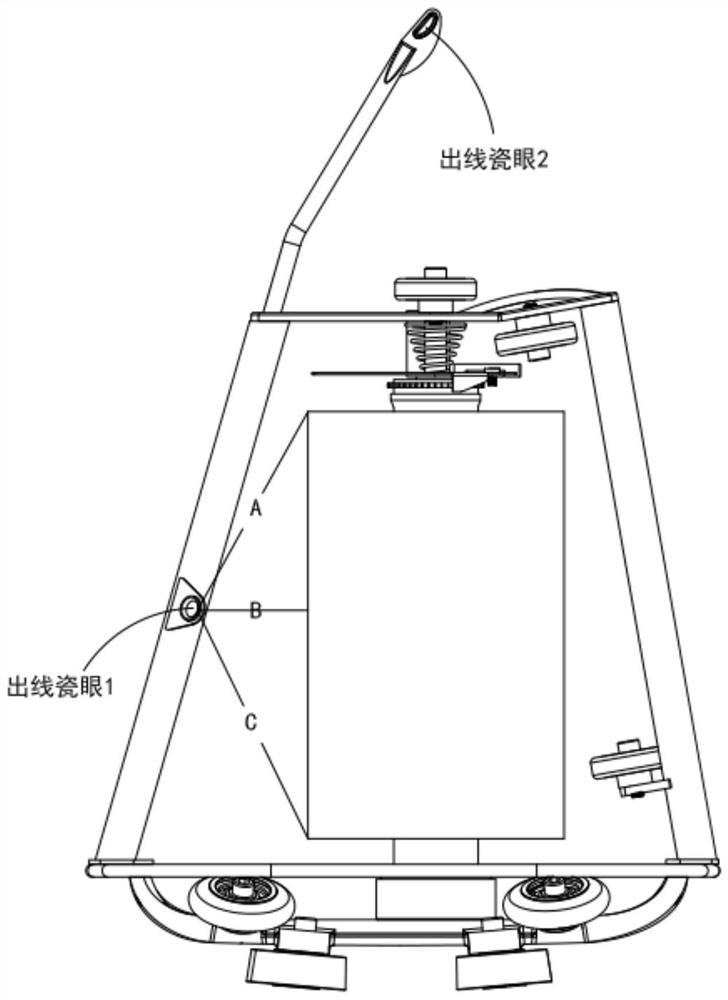

[0027] Please refer to Figure 4 , Figure 5 and Figure 10 , the tension balance shuttle includes a frame body 10, the frame body 10 is provided with a porcelain eye 12, and a yarn shaft 14 for installing a yarn roll 30. Also includes a balance assembly 20, the balance assembly 20 includes a balance plate 21, the balance plate 21 is provided with an arc surface 212, the thread is drawn out from the outlet point of the yarn roll 30, and reaches the porcelain eye 12 after passing through the arc surface 212 , the arc surface 212 makes the lengths of the silk from any exit point of the yarn roll 30 to the porcelain eye 12 equal.

[0028] After the thread is drawn out from the outlet point of the yarn volume 30, it first passes through the arc surface 212 of the balance plate 21 and then reaches the porcelain eye 12. Owing to adding bal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com