Cable extruder constant tension wire storing device utilizing magnetic effect

An extruder and constant tension technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve problems such as increased tension, thin wire diameter, and insufficient technical considerations, etc., to achieve the lifting volume The effect of line quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

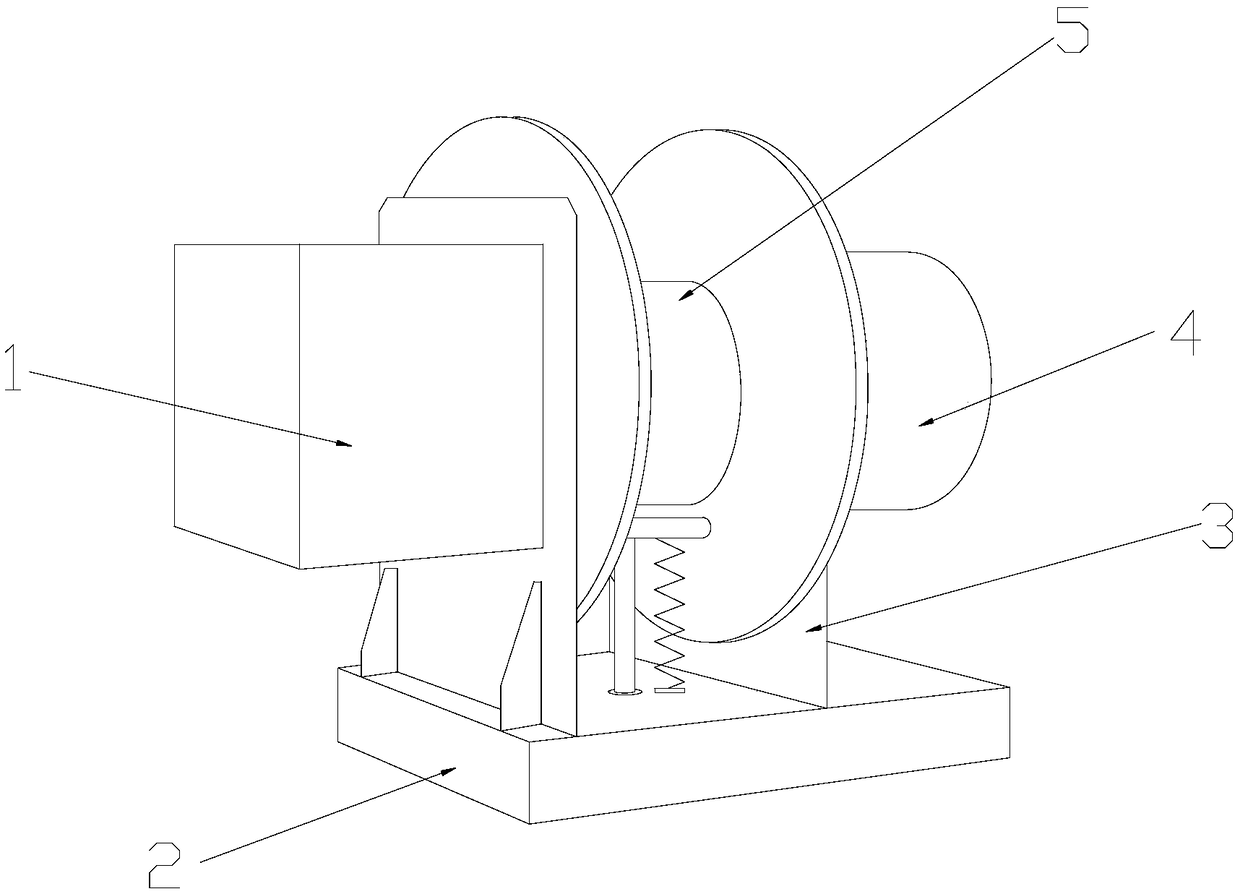

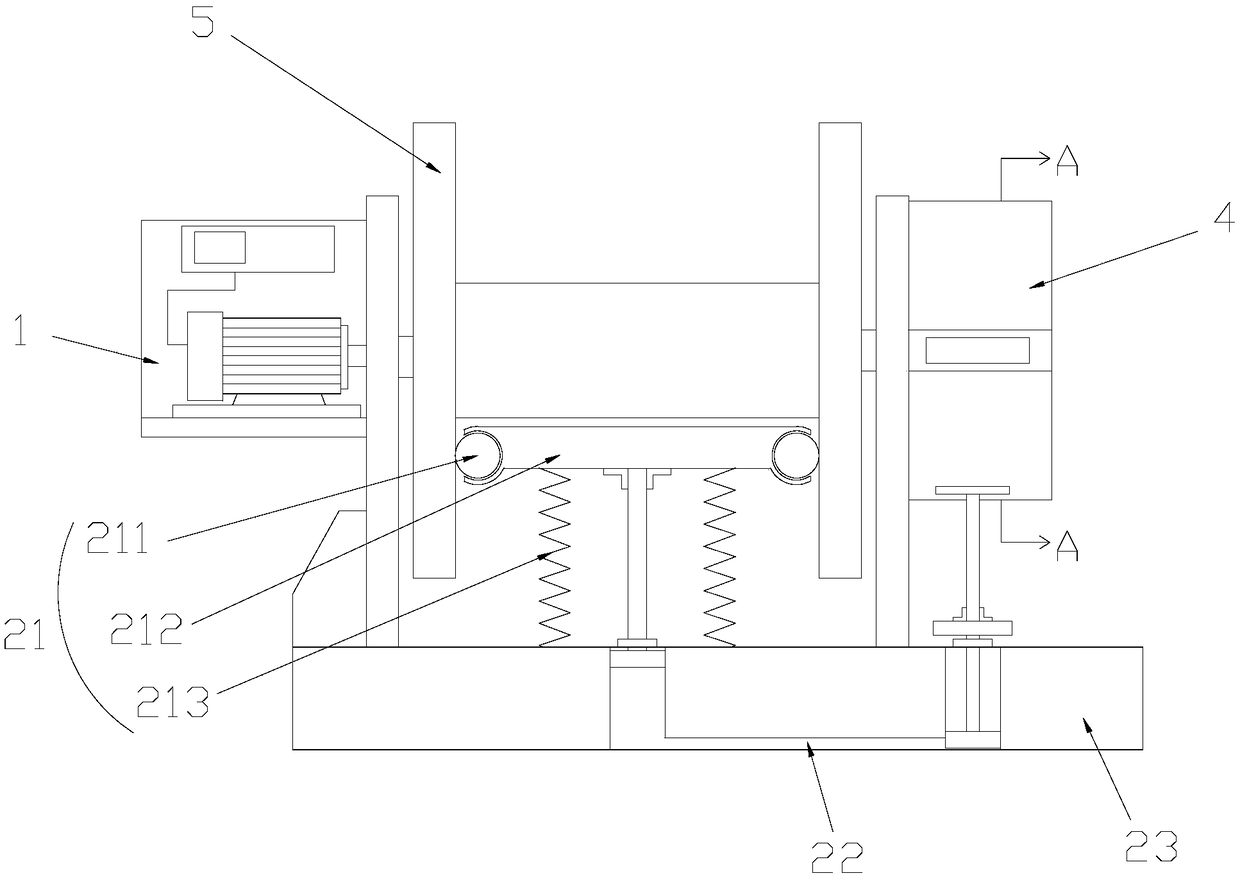

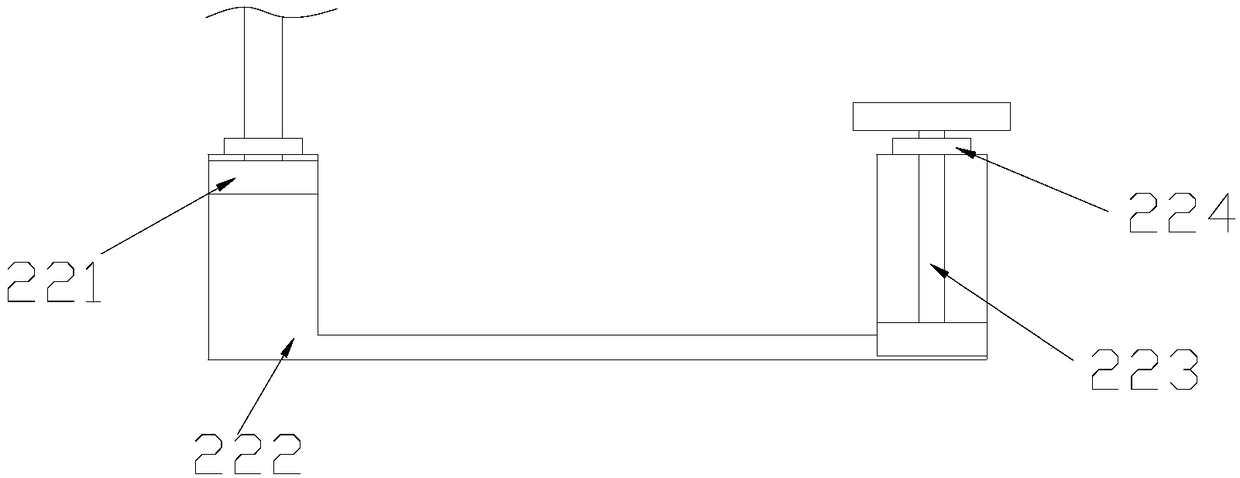

[0024] see Figure 1-Figure 2 , the present invention provides a constant tension wire storage device for a cable extruder using magnetic effects, the structure of which includes an electric drive structure 1, a cable detection device 2, a reel holder 3, a magnetic force adjustment device 4, and a reel body 5, The reel holder 3 is provided with two vertically welded to the left and right ends of the upper surface of the cable detection device 2 respectively, and the reel main body 5 is nested in the middle of the reel holder 3 and tightly connected to the cable detection device 2. Close together, the electric drive structure 1 is welded in the middle of the left surface of the reel fixing frame 3 and mechanically connected with the reel main body 5, and the magnetic force adjustment device 4 is installed on the right end of the reel main body 5 and the reel is fixed The right side surface of the frame 3; the cable detection device 2 is composed of a disc diameter detection str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com