A Wrap Angle Adjustable Expanding Device with Cloth Length Compensation Function

A cloth length compensation and widening device technology, applied in the direction of fabric elongation, textile and papermaking, fabric surface trimming, etc., can solve problems such as affecting the quality of sanding, and achieve the effect of maintaining fabric tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

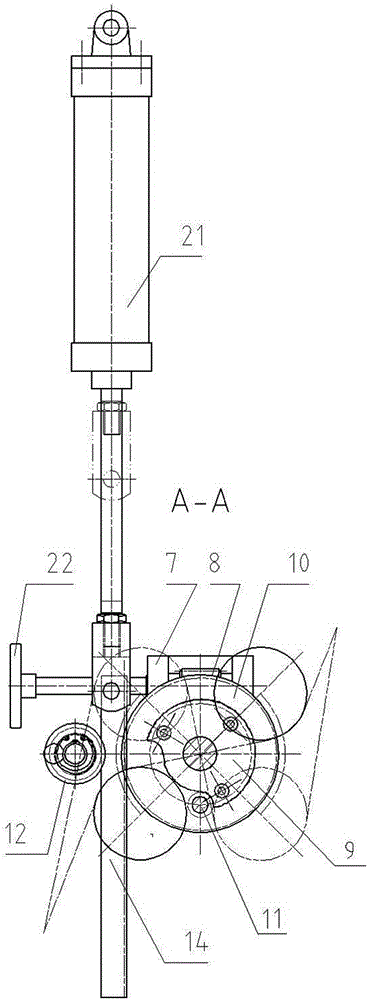

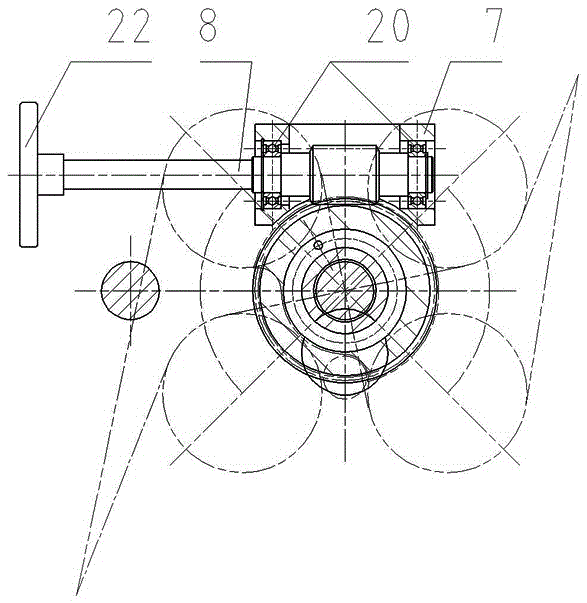

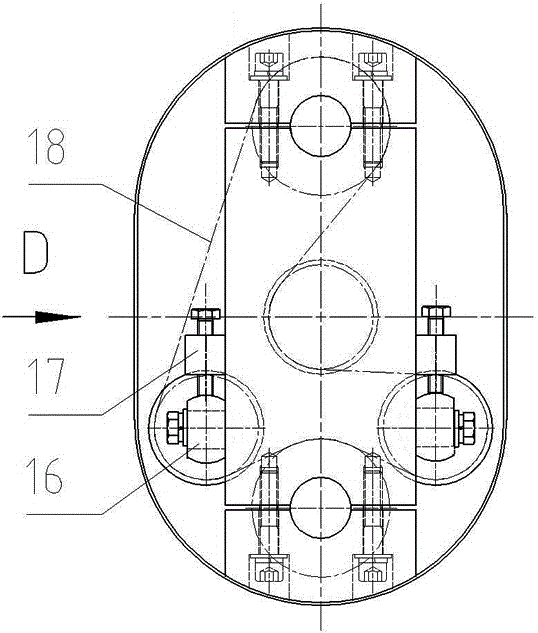

[0015] Example 1: as attached figure 1 , figure 2 , image 3 , Figure 4 and Image 6 As shown in the figure, a wrap angle adjustable expansion device with cloth length compensation function includes a frame, an expansion roller drive assembly 1, an expansion roller assembly 2, a worm gear assembly for wrap angle adjustment, and a timing belt pressure roller assembly 16 , wherein the expanding roller drive assembly 1 is sleeved in the center hole at the right end of the expanding roller assembly 2, the synchronous belt pressing wheel assembly 16 is fixed on the support plate at the right end of the expanding roller assembly 2, and the synchronous belt pressing wheel assembly 16 includes several synchronous pulleys, Between the synchronous pulleys, there is a reverse-rotating double-sided synchronous belt 18, the adjustment code 17 is installed with bolts, the synchronous belt pressing wheel assembly 16 is supported and the synchronous belt is tensioned. A gear 10 is provi...

Embodiment 2

[0017] Example 2: as attached Figure 5 As shown, the synchronous belt pressing wheel assembly 16 includes a plurality of synchronous pulleys, and a co-rotating double-sided synchronous belt 19 is arranged between the synchronous pulleys. Others are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com