Cable-forming machine by utilizing centrifugal adjustment tension

A cable forming machine and tension technology, which is applied in the direction of cable/conductor manufacturing, electrical components, circuits, etc., can solve problems such as different cable tension, waste wire, and insufficient cable consideration, so as to ensure constant tension, improve processing quality, Avoid the Serpentine Bending Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

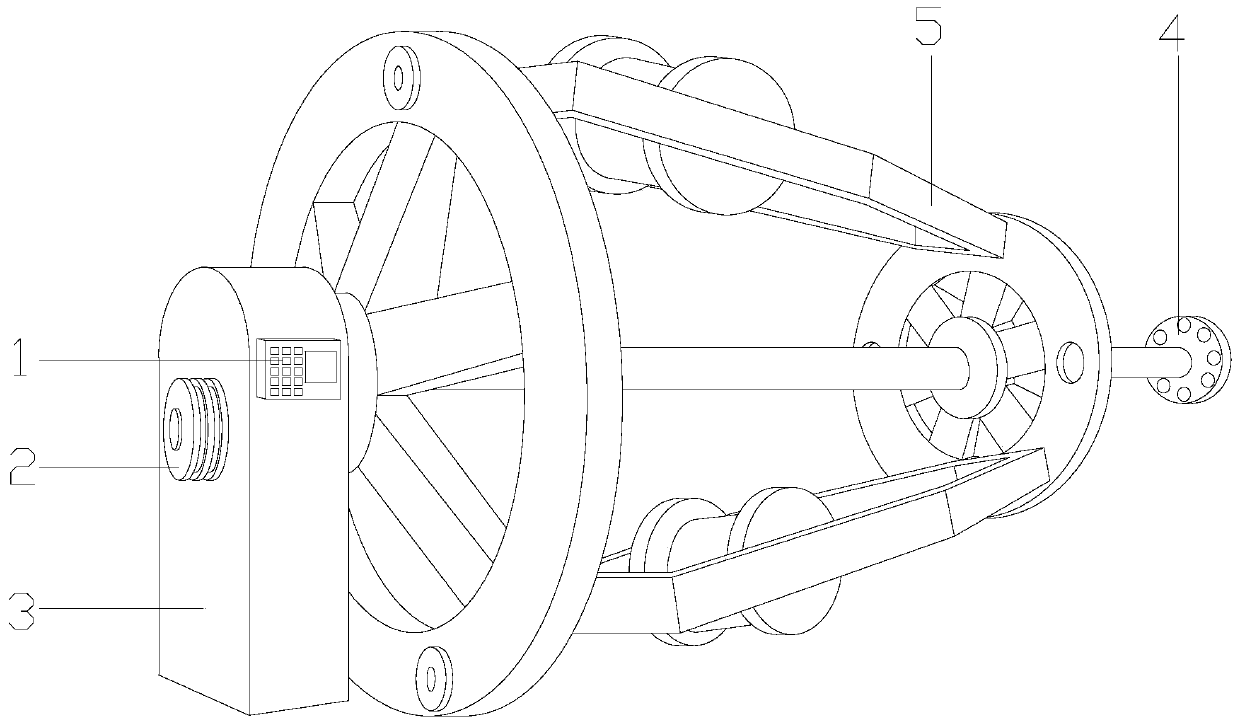

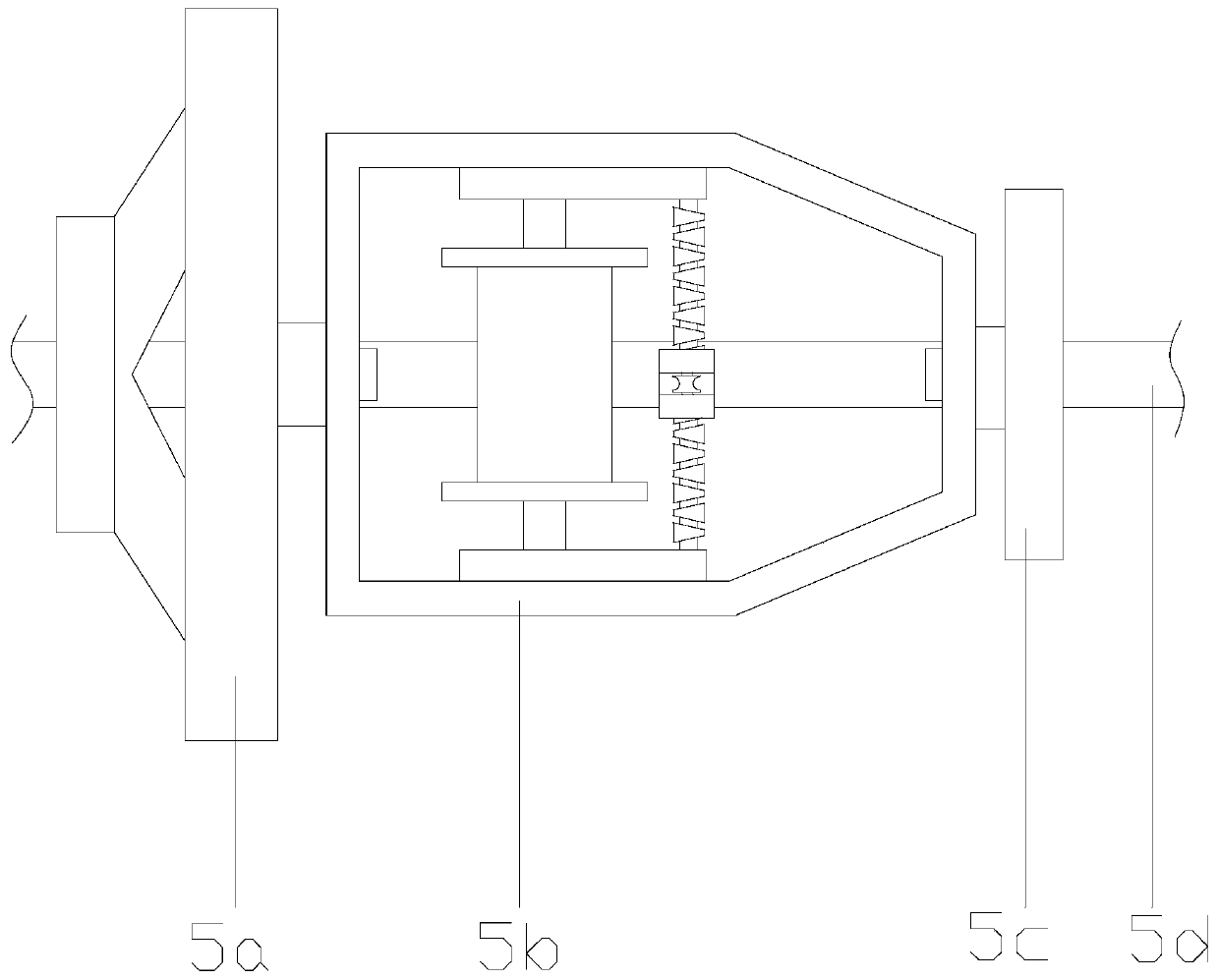

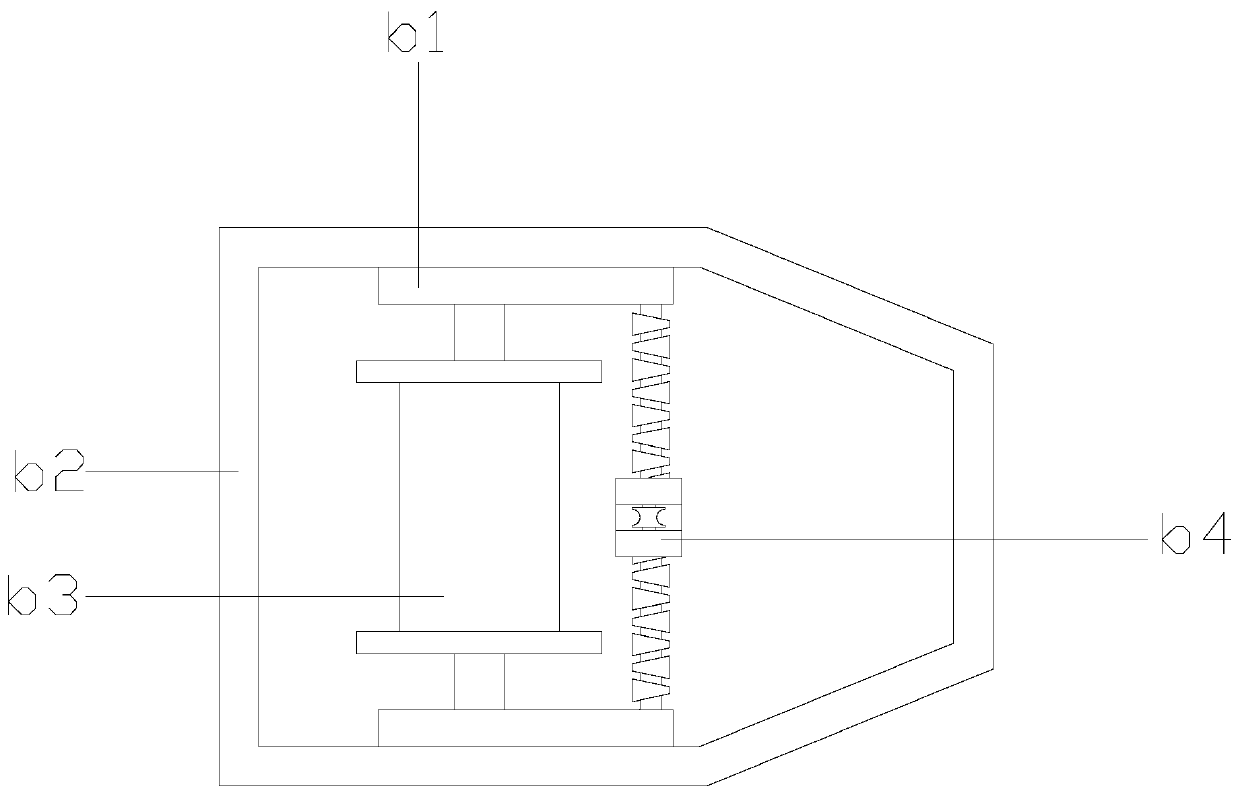

[0030] see Figure 1-Figure 2 , the present invention provides a cable forming machine using centrifugal tension adjustment, its structure includes a control panel 1, a belt drive shaft 2, a drive gear box 3, a cable traction reel 4, a cable cradle frame 5, and the drive gear box 3 is vertically Placed on the floor of the workshop, the control panel 1 is nested on the top right side of the drive gearbox 3, the belt drive shaft 2 is connected through the front of the drive gearbox 3 from top to bottom, and the cable cradle 5. The left side is interlocked with the drive gear box 3. The cable traction plate 4 is a cylindrical structure and the middle of the front is welded together with the right end of the cable cradle frame 5. The cable cradle frame 5 is composed of the first fixed plate 5a, the cradle frame The main body 5b, the second fixed disk 5c, and the driving shaft 5d are composed. The left end of the driving shaft 5d is interlocked with the driving gear box 3. The midd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com