Template sewing machine for down jackets

A technology for sewing machines and down jackets, which is applied in the direction of sewing machine components, sewing machine needle holders, sewing machine ring mechanisms, etc., which can solve problems such as uneven distribution, uneven plane pressure, and unfavorable use, so as to prevent uneven distribution and facilitate uniformity Distribution, the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The application will be described in further detail below in conjunction with the accompanying drawings. It is necessary to point out that the following specific embodiments are only used to further illustrate the application, and cannot be interpreted as limiting the protection scope of the application. The above application content makes some non-essential improvements and adjustments to this application.

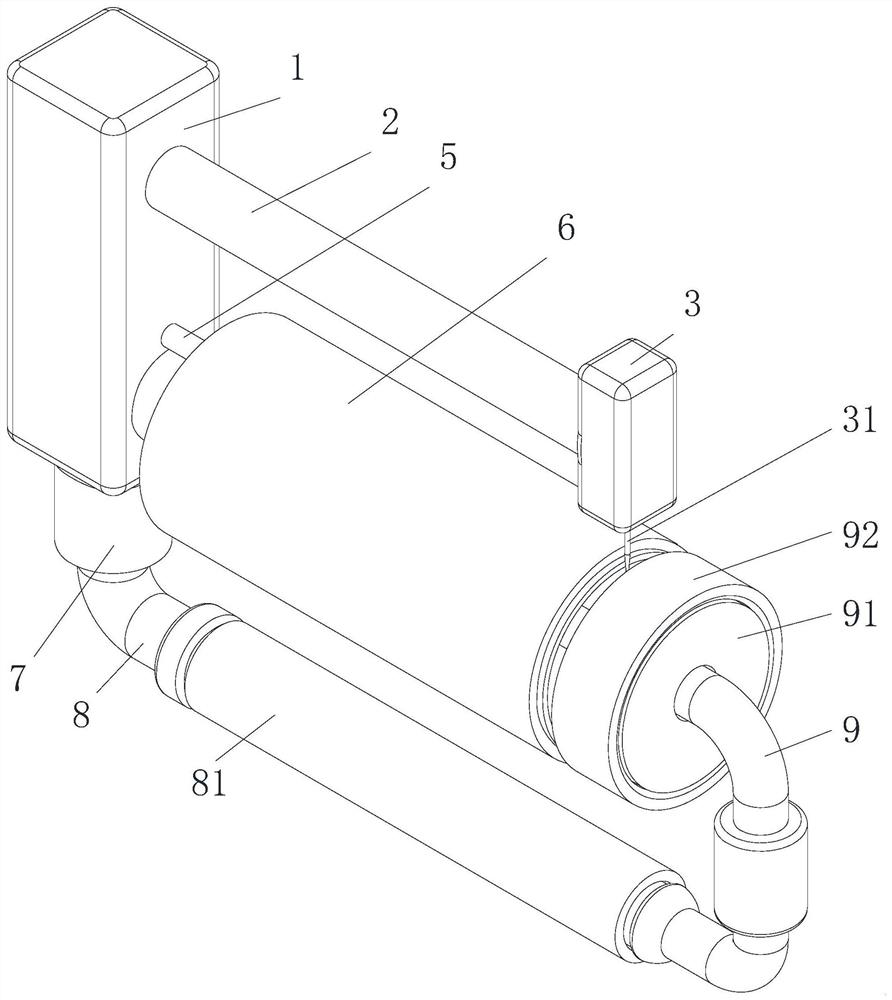

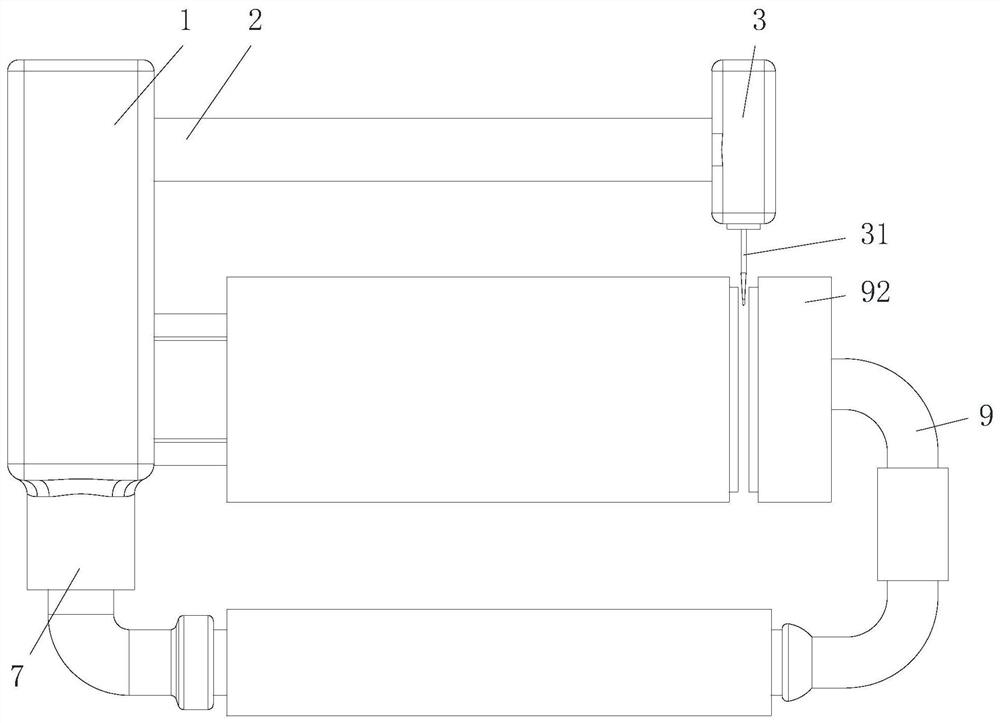

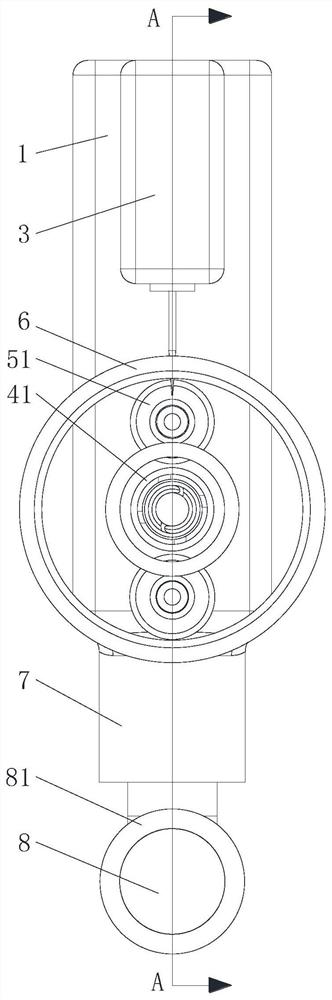

[0023] Such as Figure 1-4 As shown, a template sewing machine for down jackets in this embodiment includes a power module 1 and a first dowel bar 2 and a second dowel bar 4 respectively meshed with the power module 1, and the first dowel bar 2 The end is provided with a threader 3, the threader 3 is provided with a needle 31, the needle 31 and the shuttle 41 are in the same plane, the end of the second dowel 4 is provided with a shuttle 41, the threader 3 and the shuttle 41 are mutually Cooperate to complete the cloth sewing, the power module 1 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com